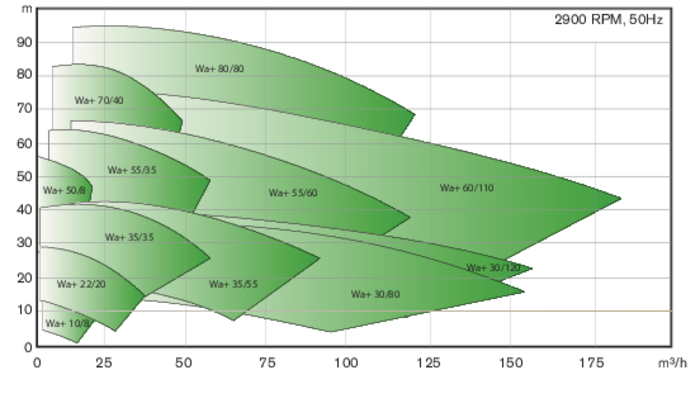

Wa+ Series - Aseptic Centrifugal Pumps

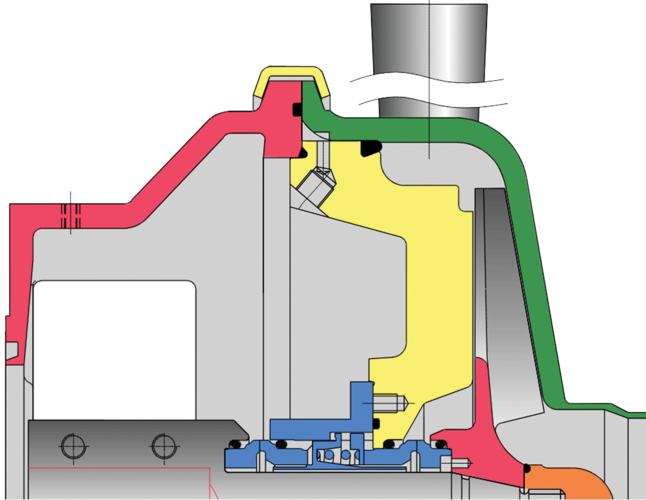

Aseptic version of the W+ Pump with double seal barrier fluid at all connections.

FEATURES

Environmental requirements are getting strict. But today, aseptic production is already essential to certain processes - including the manufacture of long life food and pharmaceutical products. The Wa+ pump is the perfect solution. All seals, including the shaft seal, are designed as double seals.

- Double mechanical shaft seals fitted for sterile flushing

- Double O-ring sealing of pump housing fitted for sterile flushing

- Special aseptic fittings fitted for sterile flushing

Wa+ pumps ensure absolutely aseptic production processes with barrier media up to 150°C (320°F). With a Wa+ pump, the risk of contaminating the product and environment is thus reduced to an absolute minimum. Wa+ pumps are 3-A (optional) and EHEDG (European Hygienic Engineering & Design Group) certified.

Wa+ pumped products ensure aseptic production processes with barrier media up to 320ºF (150ºC). With a Wa+ pump, the risk of contaminating the product and environment is thus reduced to an absolute minimum.

- Double mechanical shaft seals fitted for sterile flushing

- Double o-ring sealing of pump housing fitted for sterile flushing

- Special aseptic fittings fitted for sterile flushing

|

|

Pump with double seal barrier fluid at all connections. |

Aseptic Fitting |

The W+ pump series is based on a proven hydraulic design that promotes high operational efficiency and reduces noise and vibration levels while maintaining hygienic standards.

Low viscous fluids enter through the center inlet and flow around the impeller which turns at various speeds based on application requirements. The fluid then moves to the outer extents of the impeller vanes by centrifugal force and is directed through the outlet. As with other SPX FLOW centrifugal pumps, impeller and casing designs are optimized to perform more efficiently over a wide range of operating conditions. The casing and port are further designed to maximize performance under low NPSH conditions.

- 1 - Unique spiral volute positioned in the back plate of the pump ensures a direct transfer of liquid from inlet to outlet

- 2 - Advanced, high efficiency impeller design

- 3 - Extended outlets smooth transition to process piping while reducing turbulence and preventing product build-up

- 4 - Heavy walled pump casing insures that efficiency levels are maintained even at high pressure