Tigex® Draught Stabilizers

Draught stabilizers keeps the draught constant during the entire heating season and thereby secures optimal combustion. The draught stabilizer is also very important in ventilating condensate in the chimney.

FEATURES

- Constant Draught in the Chimney

- Fuel Savings

- Reduced influence on the environment

- Improved operation reliability

- Eliminates risk for soot fire

- Prevents chimney damages caused by condensation

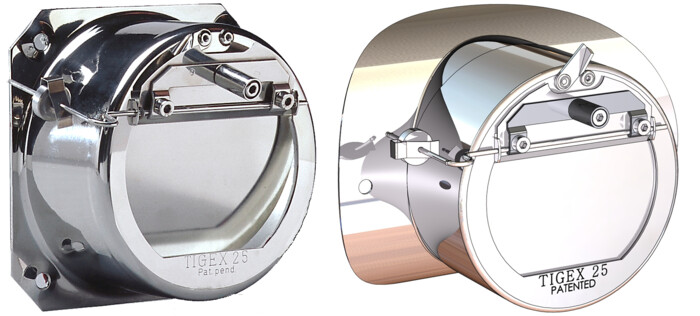

- Counter-balanced damper Tigex 25, allowing it to be fitted in almost any position (angled, vertical or horizontal)

- Gas-tight design Tigex 100-150-180, no exhaust fumes will leak into the heating area through the draught stabilizer

- Quiet operation

- High quality stainless steel design and high-temp (1000°C) superwool sealing material

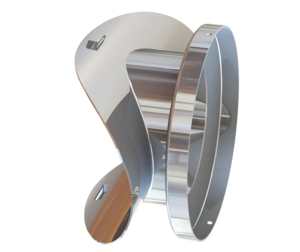

Gas tight

The ingenious, gas-tight design of the Tigex 100-150-180 allows the damper flap to close tight against the seal at the opening. By mounting the damper flap axel on the rear (back side), away from the opening, there is no leakage of exhaust fumes through hinge or axel joints. This allows the Tigex to close completely tight. The axel joint is also self-cleaning.

Technical Data

| Article Number | Description | Inner Ø (mm) | Draught Adjustable | Air group DIN 4795 |

| 60400 | Tigex 100 Stainless Steel, Shiny | 108 | 10-35 Pa | 1 - 2 |

| 60402 | Tigex 100 Stainless Steel, Black | 108 | 10-35 Pa | 1 - 2 |

| 61500 | Tigex 150 Stainless Steel, Shiny | 150 | 10-35 Pa | 1 - 4 |

| 61502 | Tigex 150 Stainless Steel, Black | 150 | 10-35 Pa | 1 - 4 |

| 61800 | Tigex 180 Stainless Steel, Shiny | 180 | 10-35 Pa | 1 - 5 |

| 61802 | Tigex 180 Stainless Steel, Black | 180 | 10-35 Pa | 1 - 5 |

Capacity

The chimney height, diameter/area and capacity will determine the correct size of the draught stabiliser.

| Model | Approx Capacity | Max. chimney height | Max. chimney dia. / area |

| Tigex 100 | up to 25 kW | up to 8 m | Ø130 mm / 132 cm² |

| Tigex 150 | up to 100 kW | up to 15 m | Ø200 mm / 314 cm² |

| Tigex 180 | up to 250 kW | up to 15 m | Ø280 mm / 615 cm² |

DIN 4795

Tigex draught stabilisers have been vigorously tested according to DIN 4795, which specifies air flow in m3/h.

Tigex 100 meets criteria for Air Group 1 - 2

Tigex 150 meets criteria for Air Group 1 - 4

Tigex 180 meets criteria for Air Group 1 - 5

Counter-balanced

Tigex draught stabilizer, developed and patented by SPX Tigerholm, is manufactured in stainless steel and is the market's only draught stabilizer with a fully balanced damper. In practical terms, this means it can be fitted in almost any position (angled, vertical or horizontal). Since its market introduction in Sweden in 1994, Tigex continues to be the first choice among the HVAC installers and boiler manufacturers of the private house segment.

Technical Data

| Article Number | Description | Draught Adjustable |

| 60300E | Tigex 25 for mounting on flat collector box or bracket plate | 5-325 Pa |

| 60390/100E | Tigex 25 with adapter for round chimney - Ø 100 mm | 5-25 Pa |

| 60390/115E | Tigex 25 with adapter for round chimney - Ø 115mm | 5-25 Pa |

| 60390/120E | Tigex 25 with adapter for round chimney - Ø 120mm | 5-25 Pa |

| 60390/130E | Tigex 25 with adapter for round chimney - Ø 130mm | 5-25 Pa |

| 60390/150E | Tigex 25 with adapter for round chimney - Ø 150mm | 5-25 Pa |

Capacity

The chimney height, diameter/area and capacity will determine the correct size of the draught stabiliser.

| Model | Approx Capacity | Max. chimney height | Max. chimney dia. / area |

| Tigex 25 | < 25 kW | < 8 m | Ø125 mm/169 cm² |

Efficiency & reliability

Weather and wind conditions can vary drastically over the course of a year leading to a wide range of draught conditions in the chimney. On cold days with high wind conditions, the draught increases, while on calm, warm days there may be no draught at all. This leads to different draught conditions inside the fire chamber as the burner fan will give different amounts of air depending on the conditions. A properly dimensioned and correctly installed draught stabilizer will automatically and continuously allow only the necessary amount of combustion air to pass through the boiler resulting in an optimal efficiency rating.

Draught variations in the chimney influence the velocity of the exhaust fumes as they pass through the boiler, which effects heat exchange. For example, if draught conditions are too high when burning solid fuels, the time for carburetion and contact with the heat exchanger is too short, which leads to low thermal efficiency, poor combustion and eventually even problems in operation. Simply put, without a proper draught stabilizer, much of the heat produced in the boiler will be lost through the chimney.

Energy savings

The biggest energy losses in installations without draught stabilizers arise due to increased soot build up, breakdowns and unburned particles. Experience has shown that the total yearly savings for an installation with a properly designed and installed draught stabilizer is up to 10%, depending on various conditions.

Irrespective of whether the boiler is fired with oil, gas, pellets or wood, a stable draught in the chimney is important for combustion conditions in the burner chamber.

Prevent condensation

Condensation in chimneys can occur due to a number of various factors. The condensation that runs along the inside walls of the chimney consists mainly of water, but also contains corrosive acids. This is extra sensitive in a brick chimney since condensation leads to erosion and cracks from freezing.

The material in a chimney always maintains a lower temperature than the exhaust gas. It is important that the exhaust gas temperature is at least 10° C (50° F) above the dew point temperature when measured at 0.5 m (20") from the top of the chimney.

Installing a Tigex draught stabilizer will allow dry air from the boiler room to enter the chimney. This provides a certain amount of dilution to the exhaust gases during operation, which increases exhaust gas circulation and decreases the dew point by approx. 10° C (50° F) . This also provides a certain amount of drying while the burner is in stand by position.

Dew point

(temperature at which steam in exhaust gas starts to condensate)

| Pellets: | 45° C (113° F) at 13% CO2 |

| Oil: | 47° C (117° F) at 13% CO2 |

| Gas: | 57° C (135° F) at 13% CO2 |

The dew point temperature varies depending on CO2 content - the lower the CO2 content, the lower the dew point.

Draught stabiliser location

The optimal placement depends mainly on the task it must fulfil. Possible placements include; on connection pipe directly after the boiler via an adapter for round pipes. It is possible to build it in the brickwork above the boiler or under the flue pipe. Special adapters must be used in the latter two cases for building into brickwork.

Always install a Tigex

A large number of domestic oil boilers that are sold today are replacements for older heating installations. They are often connected to old chimneys and/or chimneys with insufficient insulation. These older chimneys often have an open area that is too large for today’s modern and efficient boilers. When changing from oil heating to wood or pellets, the problem is often the opposite since smoke gas volumes increase when burning solid fuels, demanding a larger area.

The best solution is to install a correctly dimensioned stainless steel pipe in the chimney in combination with a Tigex draught stabilizer. Installing only the stainless steel pipe without a Tigex would make it impossible to regulate stable combustion conditions in the burner chamber throughout the year. Not using Tigex also increases the risk of condensation.

Tigex100 Adapter

Tigex100 Adapter Tigex150 Adapter

Tigex150 Adapter Tigex180 Adapter

Tigex180 Adapter