D4PMO Series - Double Seat Mixproof Valves

Used for the reliable separation and continuous processing of dissimilar fluids in Grade A dairy, the D4PMO Series helps fulfill today’s customer demands.

FEATURES

The next generation of mixproof valve technology is the result of continued development from both APV™ and Waukesha Cherry-Burrell™ process technologies. Used for the reliable separation and continuous processing of dissimilar fluids in Grade A dairy, the D4PMO Series helps fulfill today’s customer demands for production flexibility, high productivity, rapid return on investment (ROI), and enhanced product quality across various applications in the fluid milk, cheese, cream, whey, and yogurt industries. High value, Low life cycle costs:

- Newest generation continuous process PMO valve helps maximize plant uptime and allows flexibility in cleaning and dairy production schedules

- “All In” standard features provide exceptional value and help to increase ROI to align with customer budgets

- Reduced inventory costs with same seal kit used on multiple size ranges such as one kit for 1.5" - 3.0" sizes

- Minimal CIP losses improve cost savings

- Low air consumption and air supply requirements

- Long housing ports ease manifold building

- Integrated shaft seal flush reduces need for external piping

- Mixed sizes and legacy centerline dimensions available to fit complex or existing installations with minimal piping rework

Reliable performance:

- Innovative control unit design for fully integrated position and seat lift detection without external sensors

- Fully balanced design helps to prevent hydraulic blocking, withstand pressure spikes, and enables flexible flow direction without slamming

- Light overall weight helps support handling without lifting tools

- Slim stainless actuator is fully enclosed to prevent fluid ingress

- No compressed air needed for removal and servicing

Cleanability:

- Designed to the latest 3-A Sanitary Standard 85-02 for PMO compliance

- Demonstrated ability to clean product-contact surfaces without full actuation of the valve

- Integrated flow channels clean product-contact portions of the upper balancer during seat lift movement so no cumbersome adapters or external piping are required

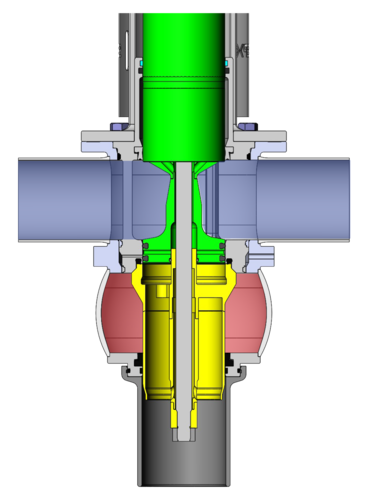

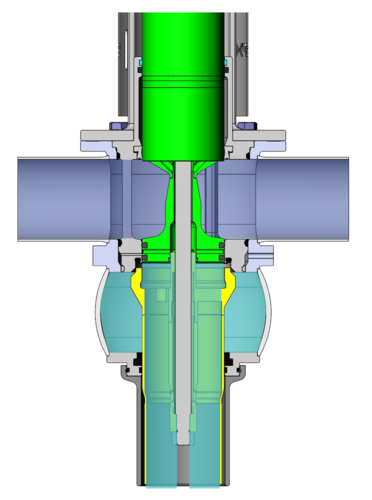

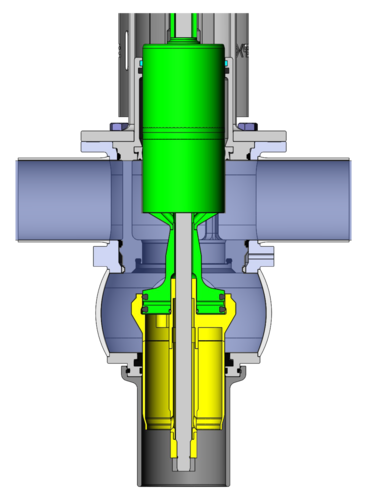

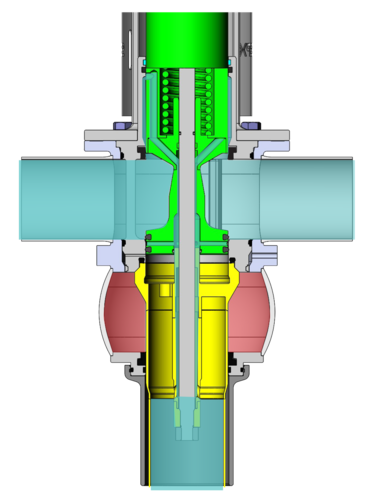

Double seat mixproof valves are used to efficiently process two different fluids (typically product and CIP) through the valve simultaneously. The D4PMO mixproof design has two seats which isolate the upper and lower pipe lines when the valve is in the fail-safe closed position. The innovative atmospheric vent cavity design in between the seats creates dual paths for any leakage should the seals fail as well as a drain for CIP solution during seat cleaning. Also, the upper seat clean movement allows integrated CIP flows to clean the portion of upper balancer exposed to product when open without the need for external flush piping.

Product 1 = Dark Blue/Purple

Product 2 - Red

CIP = Light Blue Turquoise

Valve Closed

Lower Seat Clean

Valve Open

Upper Seat Clean

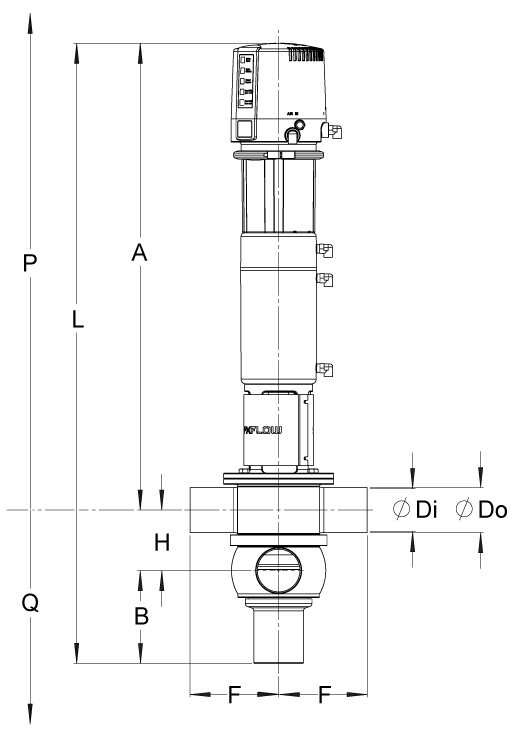

DIMENSIONS & SPECIFICATIONS

| DIMENSIONS INCH | A | A1 | B | øDa | øDi | F | H | L | L1 |

|---|---|---|---|---|---|---|---|---|---|

| 1.5 | 25.6 | 28.1 | 4.7 | 1.5 | 1.4 | 4.9 | 2.5 | 32.7 | 35.2 |

| 2.0 | 25.8 | 28.3 | 4.9 | 2.0 | 1.9 | 4.9 | 3.0 | 33.6 | 36.1 |

| 2.5 | 25.9 | 28.4 | 5.2 | 2.5 | 2.4 | 4.9 | 3.4 | 34.5 | 37 |

| 3.0 | 26.2 | 28.7 | 5.4 | 3.0 | 2.4 | 4.9 | 3.9 | 35.4 | 37.9 |

| 4.0 | 30.8 | 33.3 | 6.1 | 4.0 | 3.8 | 5.6 | 4.9 | 41.4 | 43.9 |

Minimum clearance required for installation and valve insert removal

| DIMENSIONS INCH | P (from centerline, above valve) | Q (from centerline, below valve) |

|---|---|---|

| 1.5 | 34.3 | 7.8 |

| 2.0 | 34.6 | 8.5 |

| 2.5 | 35.0 | 9.2 |

| 3.0 | 35.4 | 9.9 |

| 4.0 | 39.0 | 11.9 |

NOTE: Add the following approximate dimension to "F" for each clamp port connection 0.5" for valve sizes 1.5" - 3.0", 0.62" for valve size 4".