Workholding Devices

Features

Hytec’s air advance work supports have a spring return plunger which uses air pressure to extend it to contact the workpiece. To support any externally applied loads, the sleeve surrounding the plunger grips the plunger and holds it in place.

Air advance work supports allow the plunger to be retracted out of the way during workpiece load/unload operations. Applying air pressure to the work support gently raises the plunger until it contacts the workpiece. Adjusting the air pressure will vary the plunger contact force. The air pressure within the work support also serves to keep contaminants out.

The No. 100876’s threaded body may be compactly manifold mounted in your fixture or choose the No. 100877 which includes the 100876 work support and a mounting base for installation on a flat surface for conventionally plumbed circuits. Both feature fully corrosion resistant construction.

Extremely close manufacturing tolerances hold the plunger perpendicular to the workpiece and eliminates inaccuracies due to plunger movement during lock-up. After lock-up, the plunger is absolutely rigid and limits elastic deflection to .00007" per 100 lbs. of load. For base only, order number 500036.

- 1,300 lbs. capacity @ 5,000 psi maximum

- Fully corrosion resistant construction

- Manifold mount or conventional base mounting

- 1,000 psi minimum recommended pressure

View Catalog - Air Advance ‖ US

Features

Hytec’s block style cylinders are double acting only and do not contain return springs, making them perfect for applications where rapid positive return is essential or where both pushing and pulling forces are required.

Now, more applications are possible thanks to the new threaded piston rods. Hytec threaded inserts or any custom designed attachments may be used.

The cylinders can be mounted from top or bottom using a single cap screw and either the thru-hole on the top or the tapped hole in the bottom. A locating hole in the bottom can be used to prevent rotation when necessary. Cylinder control can be simplified in certain applications by supplying one side of the cylinder with a constant air pressure source to supply the return force. The other port of the cylinder can then be pressurized and released as if it were single-acting.

- Threaded, plated piston rod

- Double-acting

- Single screw mounting

- Piston threads withstand full retract forces

View Catalog - Block Style Cylinders ‖ US

Swing/Pull

Features

- Small footprint minimizes acreage on fixture

- Low profile reduces overall fixture height

- Manifold mounting eliminates exposed plumbing, reducing chip build-up on fixture

- “Live Roller” design provides industry’s most reliable swing/pull mechanism

- Piston/Cam combination provides solid path for clamping action

- Typical ball and groove mechanism has higher potential for clogging and for damage from mis-aligned work pieces

- Simple cavity design enables faster fixture building

- Available in single and double acting versions

- Special rod wiper seal protects internal clamp components

- Unique drainage system channels contaminants away from clamp

- Corrosion resistant construction

- Heat treated, chrome plated piston rod

- Manifold mountable

- Unique “Live Roller” swing mechanism for increased service life

- Power-Tech™ heat treated body and hardened cam for long wear and corrosion resistance

- Single-acting and double-acting models

- Straight pull capacity 480 - 5,900 lbs. at 5,000 psi max.

View Catalog - Cartridge Swing/Pull Clamps (US)

Features

These cylinders retract when hydraulically pressurized to exert a pulling force on clamping elements or mechanisms. For straight pull applications only, they allow the user to design a cylinder into a fixture while maintaining the replaceability and long life of a heat treated, corrosion resistant cylinder body. Designed for single-acting systems only, the cylinder’s return spring is built into the piston and requires no additional fixture space.

The pull cylinders are designed for cartridge mounting in a cavity supplied by the fixture builder. The required cavity is simply a cylindrical bore with a properly deburred pressure port intersecting it, providing the fluid connection. The depth of the bore matches nominal plate thickness so the cylinder can be easily “sandwiched” between two plates if desired. Where possible, pins inserted in the back of the piston are provided. These pins are guided by holes drilled in the sub-plate and will prevent cylinder rotation when adjustments are made. A breather hole should always be provided and may be combined with the pin holes where appropriate.

- Minimal space requirements

- 5,000 psi maximum

- Rod wiper excludes contaminants

- Manifold mounting eliminates exposed tubing

- Plating & Power-Tech™ processes resist corrosion

- Single-acting, spring-return

- Return spring included

- Power-Tech™ treated body for long wear and corrosion resistance

View Catalog - Cartridge Pull Cylinders

Features

Our center-hole cylinders can be used as single or double-acting workholding devices. Mounting can be done in any of several ways: use the thru-holes for mounting from the top, use the tapped holes in the bottom for mounting from underneath, or secure with a single stud or rod through the center. The pistons are threaded to accept the optional crowned threaded inserts, used when the cylinder contacts the work directly.

- Single or double-acting

- Multiple mounting options

- Heavy-duty return spring

- Converts manual clamping to hydraulics

- Plated, threaded piston rods

View Catalog - Center Hole Cylinders ‖ US

Features

This clamp is ideal for permanent installation on presses to facilitate quick die changes or can be used in many workholding applications. Its unique design allows it to be mounted simply by using a clamp riser equal in thickness to the member being clamped. Just two 5⁄8, grade 8 cap screws are sufficient to mount the clamp and resist its 11,180 lbs. maximum clamping force. For proper clamp support and minimum deflection, design the riser so that it contacts the entire clamp mounting surface.

Two pressure ports make these clamps easy to chain together without the need for an extra tee fitting for each clamp.

The clamp features a low overall height, heat treated body bronze plated piston and a piston rod wiper seal to keep contaminant's out. Intended for use in 5,000 psi maximum systems, this single acting, spring return clamp has a 0.250 inch stroke.

- Bronze plated piston and piston rod

- Heat treated, corrosion resistant body

- Rod wiper seal

View Catalog - Die Clamps ‖ US

Features:

Hytec's edge clamps perform three functions: locating the workpiece, clamping horizontally against secondary locators and clamping vertically against the primary locating surface. This combined horizontal and vertical clamping force can locate and secure many parts with no other clamps being needed.

These clamps are extremely compact relative to their clamping force and are available in either conventionally or manifold mounted versions. At only 1 inch tall, their low profile design allows them to remain below most workpieces for unrestricted machining access to a part’s top surface.

The 100986 clamp is compactly designed for manifold mounting. The 100863 clamp has three pressure ports for convenient installation and easy chaining of multiple clamps. A generous 0.188" stroke compensates for workpiece variations. Includes removable mounting/ locating bushing.

- 15 degree clamping angle

- Hardened, serrated, plated gripper

- Single-acting

- Hardened, tool steel piston

- Three pressure ports (100863)

- Compact design

- Dual, zinc plated return springs

- Conventional and manifold mount versions

View Catalog - Edge Clamps ‖ US

Features

Hytec’s fluid advance work supports have a spring-loaded plunger which hydraulically extends to contact the workpiece. To support any externally applied loads, the sleeve surrounding the plunger grips the plunger and holds it in place.

Fluid advance work supports allow the plunger to be retracted out of the way during workpiece load/unload operations. The work support provides its own internal sequencing of a piston which gently raises the plunger until it contacts the workpiece. A spring between the piston and the plunger limits the workpiece contact force.

The 100882’s threaded body may be compactly manifold mounted in your fixture or choose the No. 100883 which includes the 100882 work support and a mounting base for installation on a flat surface for conventionally plumbed circuits. Both feature fully corrosion resistant construction.

Extremely close manufacturing tolerances hold the plunger perpendicular to the workpiece and eliminate inaccuracies due to plunger movement during lock-up. After lock-up, the plunger is absolutely rigid and limits elastic deflection to 0.00004" per 100 lbs. of load. For base only, order number 500028 for conventional mounting, and 421728 for manifold mounting.

- 4,000 lbs. capacity @ 5,000 psi maximum

- Fully corrosion resistant construction

- Manifold mount or conventional base mounting

- Small, filtered breather/rest button to accommodate intricate workpieces

- 1,000 psi minimum recommended pressure

View Catalog - Fluid Advance ‖ US

Features:

These single-acting, spring-return cylinders are designed for applications where high force and low overall height are requirements. Ideal for clamping fixtures where space is limited. The crowned piston makes them perfect for powering strap clamps, linkages or for direct contact with the workpiece. Cylinder bodies are heat-treated using a special process for exceptional wear and corrosion resistance. Three sizes to choose from – the largest being only 2" high – with maximum forces ranging from 4,920 lbs. to 22,150 lbs. Each cylinder has a built-in heavy-duty spring for fast return, and case hardened piston for long service life.

The 100855 and 100925 use the same rugged design with different mounting options. Designed for side mounting, four grade 8 mounting screws can easily resist the force of the clamp so no additional stops or clamp mounting structure is necessary.

- Low overall height

- Bronze plated piston

- Piston rod wiper seal

- Heavy-duty return spring

- Heat treated and plated cylinder body

- Single-acting

- Power-Tech™ treated body for long wear and corrosion resistance

View Catalog - Low Profile Cylinders ‖ US

Manifold Mounted

Features

- Unique connector bushing provides positive mating with fixture, reducing the potential for leakage or weeping.

- Simple cavity design eliminates need for threaded holes in mating surfaces

- Manifold design eliminates external plumbing and reduces fixture height

- “Live Roller” design provides industry’s most reliable swing/pull mechanism

- Piston/Cam combination provides solid path for clamping action

- Typical ball and groove mechanism has higher potential for clogging and for damage from misaligned work pieces

- Available in single and double acting versions

- Special rod wiper seal protects internal clamp components

- Unique drainage system channels contaminants away from clamp

- Corrosion resistant construction

- Heat treated, chrome plated piston rod

- Manifold mountable

- Unique “Live Roller” swing mechanism for increased service life

- Power-Tech™ heat treated body and hardened cam for long wear and corrosion resistance

- Single- and double-acting models are dimensionally interchangeable

- Straight pull capacity 480-1,472 lbs. at 5,000 psi max.

View Catalog - Manifold Mounted Clamps (US)

Features

Single screw mounting and the adjustable clamping screw make these clamps easy to reposition on the fixture to adapt to various workpiece sizes, and make set up and adjustment faster than other methods. Plus, it enables you to work several piece sizes without changing the fixture each time. When mounted on a T-slot machine table, the need for fixtures is often eliminated.

Very similar in operation to the swing clamps, with the exception of having the clamping arm move out toward the workpiece in a straight line rather than rotating 90°, making them ideal for applications where the shape of the fixture or part does not allow room for the clamp to swing.

These clamps are available with maximum clamping forces of up to 8,295 lbs.: Minimum operating pressure is 500 psi, maximum is 3,500 psi.

- Single or double-acting

- Single screw mounting

- Internal sequence valve

- Adjustable clamping screw

- T-slot mountable

- SAE and NPT ported versions

Retract Clamp Modification Information

- Standard arm may be customized for use in specific applications.

- Standard clamping arm is 1045 steel heat treated to 38 Rc max.

- Modified/custom-designed clamping arms must be spring biased or counterweighted so that the arm pivots away from the workpiece.

NOTE: Modified arms may not have the same workpiece clamping force as standard clamps. Clamping force may be calculated by using the dimensions and cylinder force data below. Any clamp using a modified or custom arm that is heavier than the standard arm, must have its flow restricted to prevent internal damage.

View Catalog - Retract Clamps ‖ US

Features

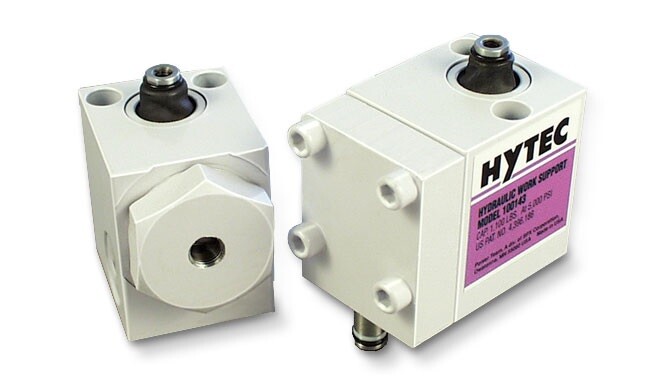

Hytec's 1,100 lb. capacity work supports use a boot attached between the body and plunger to effectively seal out contaminants. A diaphragm breather system further protects internal components, and the block style design requires only a flat surface for mounting rather than the large threaded hole needed with threaded body designs. Two mounting styles are available for plumbing convenience: manifold and conventional mount.

These work supports use a spring-loaded plunger to minimize deflection and vibration: As the workpiece is loaded into the fixture, it contacts the plunger, and its weight or the design of the fixture holds the plunger depressed. When the work support is hydraulically pressurized, the plunger is locked into position.

- Spring advance

- 1,100 lb. rated capacity at 5,000 psi maximum

- Single-acting

- Manifold or conventionally mounted styles

- Sealed against contamination

View Catalog - Spring Advance ‖ US

Surface Mounted

Externally Plumbed-Lower Flange Style

Features

- External plumbing eliminates need to gun drill additional ports in fixture

- Can be inserted from above or below fixture plate

- Top mounting provides extra height to accommodate large work pieces

- Top mounting does not require drilling of large fixture hole

- Special rod wiper seal protects internal clamp components

- Corrosion resistant construction

- Heat treated, chrome plated piston rod

- Power-Tech® treated body and hardened cam for long wear and corrosion resistant

View Catalog - Surface Mounted Clamps (US)

Features

Single-screw mounting and the adjustable clamping screw make these clamps easy to reposition on the fixture to adapt to various workpiece sizes, and make set-up and adjustment faster than other methods. It also lets you clamp several workpiece sizes without changing the fixture each time. When mounted on a T-slot machine table, the need for fixtures is often eliminated.

Two separate actuators are used to perform the clamping function. First, a cylinder is used to swing the clamping arm 90° into position over the workpiece. Then a second cylinder is sequenced to pivot the clamping arm into contact with the workpiece and hold it in place.

Twelve clamps are available with maximum clamping forces of up to 8,295 lbs.: six with right hand and six with left hand swing. Minimum operating pressure is 500 psi, maximum is 3,500 psi.

- Single or double-acting (See Threaded Body Style - 365 lbs.)

- Single screw mounting

- Internal sequence valve

- Adjustable clamping screw

- T-slot mountable

- SAE and NPT ported versions

Swing Clamp Modification Information

- Standard arm may be customized for use in specific applications.

- Standard clamping arm is 1045 steel heat treated to 38 Rc max.

- Modified/custom-designed clamping arms must be spring biased or counter weighted so that the arm pivots away from the workpiece.

- Arms must be stopped such that they do not pivot below the retracted height of the clamping cylinder.

Note: Modified arms may not have the same workpiece clamping force as standard clamps. Clamping force may be calculated by using the dimensions and cylinder force data below. Any clamp using a modified or custom arm that is longer or heavier than the standard arm, must have its flow restricted to prevent internal damage.

View Catalog - Swing Clamps ‖ US

Features

- Simple cavity design eliminates need for threaded holes in mating surfaces

- Manifold design eliminates external plumbing and reduces fixture height

- “Live Roller” design provides industry’s most reliable swing/pull mechanism

- Piston/Cam combination provides solid path for clamping action

- Typical ball and groove mechanism has higher potential for clogging and for damage from mis-aligned work pieces

- Available in single and double acting versions

- Special rod wiper seal protects internal clamp components

- Unique drainage system channels contaminants away from clamp

- Corrosion resistant construction

- Heat treated, chrome plated piston rod

- Manifold mountable

- Unique “Live Roller” swing mechanism for increased service life

- Power-Tech™ treated body and hardened cam for long wear and corrosion resistance

- Single- and double-acting models are dimensionally interchangeable

- Straight pull cap. 1,472 lbs. at 5,000 psi maximum

- Flange top or bottom mounting

View Catalog - Swing / Pull Clamps ‖ US

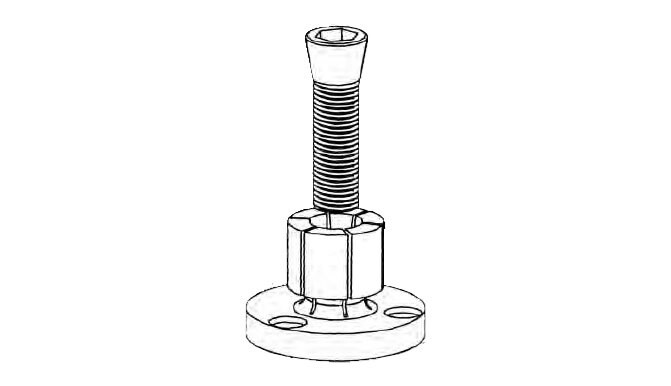

Features

Machining and Installation

Expand clamp approximately .005 over relaxed diameter and machine to fit workpiece bore, either on lathe or mill.

If machining the clamp on a lathe use the nut provided, on the back of the clamp, to tighten the tapered screw. This nut is used only to machine the clamp.

Machine a pocket, in the fixture, for the close tolerance “E” dimension and drill and tap mounting holes per “H” column. Drill and tap a hole from the “I” column in the center of the pocket for the tapered screw.

A recessed dowel pin may be installed into the flange for additional rigidity if required.

View Catalog - Tapered Screw Clamps ‖ US

Features

This is our highest capacity cylinder in the threaded body style. This premium grade cylinder includes a gland bearing, wiper seal, and extension style return spring. Its plated, threaded piston rod resists wear and corrosion and accepts Hytec threaded inserts or custom made attachments. The 100208 can be mounted by threading it into a tapped hole in the fixture or by inserting it into a drilled hole and locking it on both sides using two hex jam nuts (optional). This conventionally mounted 1" stroke, single acting cylinder has a 1/8" NPT side port for making hydraulic connections. Like our smaller, threaded body cylinders, the 110132 is intended for manifold mounting and requires only a flat-bottom hole for installation.

- Threaded body design

- Single-acting

- Threaded, plated piston rod

- Optional hex jam nut

- Rod wiper seal in gland bearing

- Power-Tech™ treated body for long wear and corrosion resistance

View Catalog - Threaded Body Cylinders ‖ US

Swing/Pull

Features

- Full thread provides wide range of precise height adjustment

- Simple installation/removal

- “Live Roller” design provides industry’s most reliable swing/pull mechanism

- o Piston/Cam combination provides solid path for clamping action

- o Typical ball and groove mechanism has higher potential for clogging and for damage from mis-aligned work pieces

- Available in single and double acting versions

- Special rod wiper seal protects internal clamp components

- Unique drainage system channels contaminants away from clamp

- Corrosion resistant construction

- Heat treated, chrome plated piston rod

- Unique “Live Roller™” swing mechanism for increased service life

- Power-Tech™ treated body and hardened cam for long wear and corrosion resistance

- 5,000 psi max.

- Straight pull capacity 480 - 5,900 lbs. at 5,000 psi max.

View Catalog - Threaded Swing/Pull Clamps (US)

Features

Our most versatile cylinder style, these threaded body cylinders are single-acting, spring-return, and can be outfitted for a wide variety of applications. Available in either Unified National Coarse or Fine threads, they’re ideal for manifold mounting, but can also be used for external plumbing connections when fitted with a feeder cap. Mounting brackets and jam nuts can be specified for added mounting versatility. The threaded pistons will accept optional Hytec pointed or crowned threaded inserts, flat faced toggle pads, or you can custom design your own attachments. These cylinders should always be used with a threaded insert to prevent damage to the workpiece and the cylinder.

- Manifold or conventional mounting

- Heavy duty return springs

- Optional jam nuts, feeder caps and mounting brackets

- Threaded, plated piston rod

- Fine or coarse threads

- “O” ring seal included

- 100% corrosion resistant

- Single-acting

- Power-Tech treated body for long wear and corrosion resistance

View Catalog - Threaded Cylinders ‖ US

Features

These clamps are a combination of Mitee-Bite® Products Uniforce® Clamp and Hytec’s cartridge pull cylinders. Two pull cylinders are offered to power each of five of the most popular Uniforce clamps. One will create the force necessary to achieve the clamp’s rated force at 5,000 psi hydraulic pressure. The other powers the clamp to its maximum rating at only 2,500 psi. This allows the efficient use of these clamps in lower pressure systems however, never exceed the maximum pressure rating of the clamp/cylinder assembly.

The pull cylinders are designed for cartridge mounting in a cavity supplied by the fixture builder. The required cavity is simply a cylindrical bore with a properly deburred pressure port intersecting it, providing the fluid connection. Where possible, pins inserted in the back of the piston are provided. These pins can be guided by holes drilled in the sub-plate to prevent cylinder rotation when adjustments are made. A breather hole should always be provided and may be combined with the pin holes where appropriate.

An external stop prevents over-travel of the clamp if actuated without a workpiece in place.

- Minimal space requirements

- Reduces repetitive motion injuries

- 5,000 psi and 2,500 psi maximum versions

- Cylinders require no additional fixture space

- Rod wiper excludes contaminants

- Plating & Power-Tech™ processes resist corrosion

- Single-acting, spring return

Mitee-Bite and Uniforce are registered trademarks of Mitee-Bite Products Company.

View Catalog - Uniforce Clamps ‖ US