FEATURES

Revolutionize Your UHT Processing

Producing premium UHT products traditionally requires significant fresh-steam input. The APV® SteamRecycle™ system redefines energy efficiency in infusion UHT technology by continuously recirculating 100% of vapor from the UHT flash vessel back into the infusion chamber. This maximizes energy recovery, significantly reduces environmental impact and delivers substantial energy savings over traditional infusion UHT systems—all while preserving the taste and quality your customers expect.

Why Choose SPX FLOW for Your UHT Processing?

SPX FLOW is a market leader in UHT technology, offering sustainable, energy-efficient solutions that ensure superior product safety. Our aseptic processing systems are rigorously tested and globally supported, delivering longer run times and smooth, reliable operations. Infusion UHT featuring SteamRecycle™ is ideal for dairy and plant-based producers looking to produce premium products with a fresh taste while reducing OPEX and total cost of ownership (TCO) and enhancing efficiency and sustainability.

Energy and CO2 Savings

-

Significant energy savings:

The high-efficiency compressor system minimizes reheating needs , lowering operational costs by reusing steam and maximizing energy recovery. -

100% Steam Recovery:

The captures low-pressure vapor and recycles it through high-speed steam compressors, eliminating the need for system new steam generation. -

Lower CO2 Emissions:

Repurposing steam in UHT milk and plant-based beverage processing lowers emissions by up to 2,000 tons annually compared with traditional Infusion UHT systems, helping you reduce your carbon footprint and achieve sustainability targets. -

Superior Steam Quality:

Optimized steam purity for dairy and plant-based applications. -

Efficient High-Pressure Steam:

Delivers reliable steam at >5 bar, ensuring consistent process efficiency. -

Seamless integration:

Integrates easily with existing systems for maximum efficiency and minimal disruption -

Independent Operation:

Works alongside your Infusion UHT system, ensuring continuous production. -

Proven Reliability:

Rigorously tested for consistent performance and smooth UHT system integration in real-world production environments, ensuring long production runs and minimal downtime. -

Easy Maintenance:

Simplified maintenance reduces downtime and operational interruptions. -

Hygienic & Compliant Design:

Meets stringent hygiene standards for safety and ease of cleaning. -

Cost Reduction and ROI:

By cutting energy costs and improving operational efficiency, you’ll see a significant return on investment with a typical ROI of 3-4* years.

*Actual ROI depends on site-specific utility rates and production parameters.

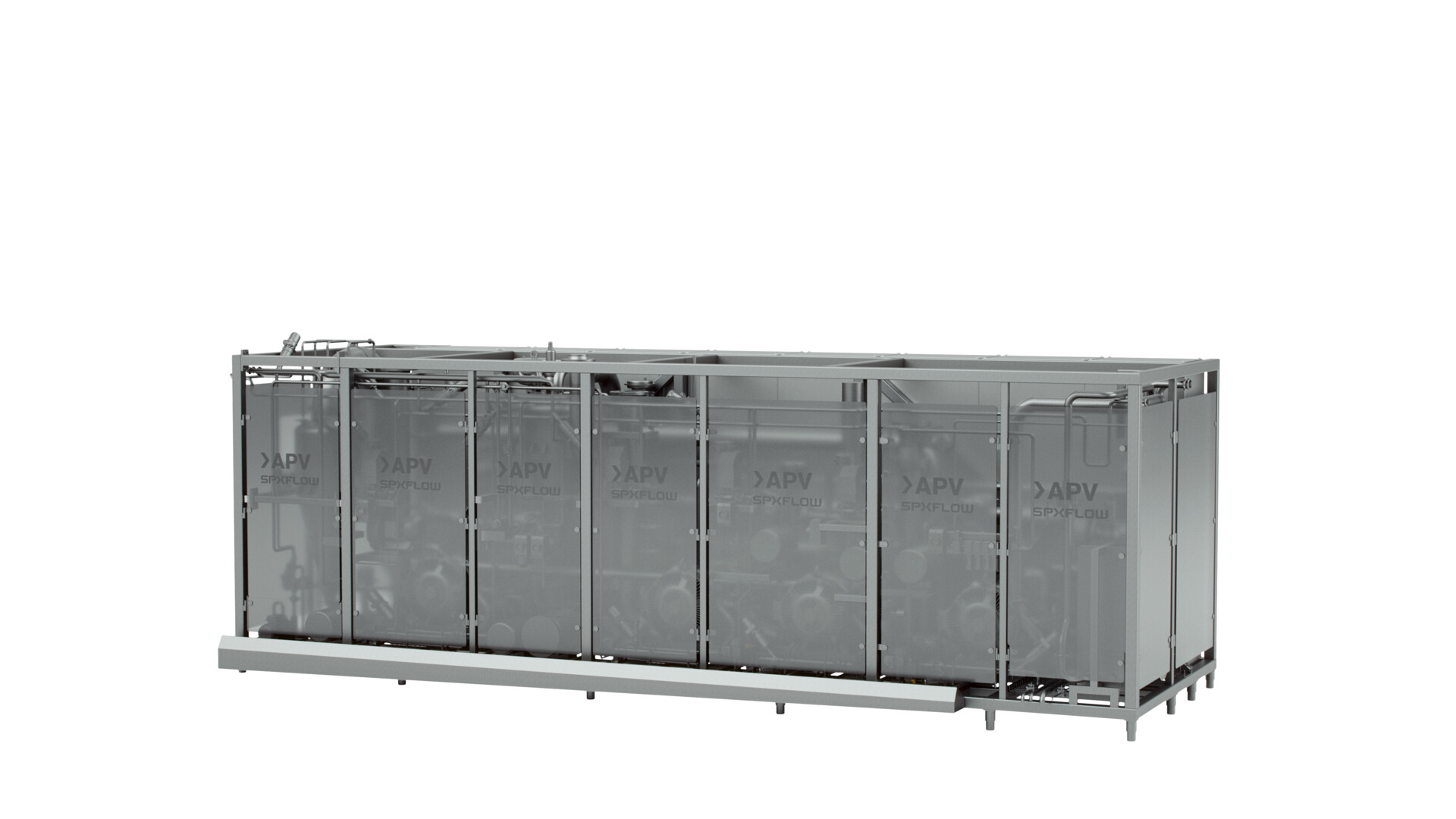

Advanced Technical Design

The APV® SteamRecycle™ system uses high-speed steam compressors with frequency converters for precision control. Vapor is collected at approximately 75°C from the flash vessel and compressed to the desired pressure and temperature for reuse. Desuperheating loops stabilize steam properties and surplus steam is managed through bypass and flow control systems for secondary uses.

Additional integrated features include:

- CIP-enabled spray balls for hygienic design

- Pressure relief valves for safety

- Flow transmitters for accurate monitoring

Make Your UHT System Climate-Neutral

By dramatically reducing energy consumption and eliminating fossil fuel dependence, the APV® SteamRecycle™ system empowers producers to operate more sustainably, without compromising on product quality or operational efficiency.

Key Applications

Dairy

- Milk

- Cream (whipped)

- Ice cream mix

- Flavored milk

Plant-Based Alternatives

- Soy drinks

- Oat drinks

- Almond drinks

- Juices

Specialized Nutrition

- Liquid breakfast

- High-protein drinks

- Infant formula

- Liquid baby food

THEORY OF OPERATION

How the SteamRecycle System Works

The APV® SteamRecycle™ system captures low-pressure steam vapor (around 75°C) from the UHT flash vessel and compresses it into high-pressure, high-temperature steam (to 145+°C at >5 bar) using high-speed mechanical vapor compressors with frequency converters. This recycled steam is then fed back into the infusion chamber, eliminating the need for continuous fresh steam generation and significantly reducing energy consumption.

To ensure stable operation, the system includes desuperheating loops for steam stabilization, integrated bypass valves for managing surplus steam and real-time monitoring of flow, temperature and pressure. Hygienic design is upheld through CIP-enabled spray balls and pressure relief valves, supporting food safety and compliance.

All product-contact components are made of stainless steel 316L (DIN EN10088), ensuring durability and sanitary performance. The continuous steam recycling process supports sustainability goals and meets the highest safety standards in UHT and aseptic processing—making it the ideal solution for energy-efficient, climate-conscious production.