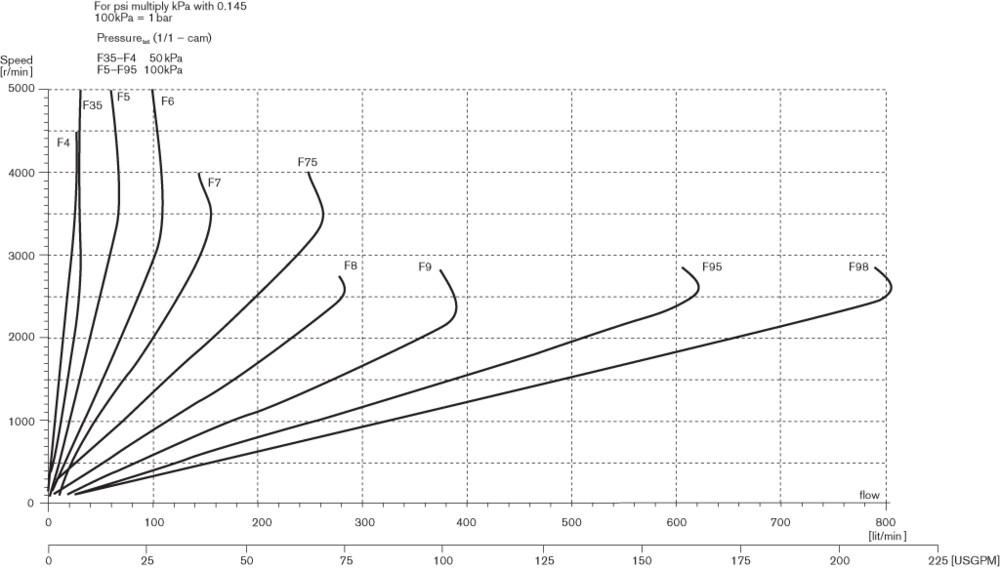

Pump Sizes F35 - F95

FEATURES

- Limited 3 Year Warranty

- Self-priming, a dry pump can lift water up to as much as 3 meters. Thus a flexible impeller pump being used for engine cooling does not need to be located below the water line or manually primed.

- Flexible impeller pumps can pass fairly large solids without clogging or damaging the pump. This reduces the need for filtering the incoming fluid.

- For general raw or fresh water applications, the standard long-lasting neoprene rubber impeller is used. All flexible impeller pumps is that they cannot be permitted to run dry for more than 30 seconds. Both the impeller and the seals depend upon the water for lubrication and will soon fail if run dry.

- Wear parts are easily replaceable

- Service kits are available for all standard models.

- Flange Mounted Pumps (F4B-9, F7B-9, F9B-9)

- Crank Shaft Pulley Mounted Pumps (F6B-9)

- Belt/Pulley Driven Pedestal Pumps (F7B-8, F8B-3000)

- Pump ports available from 3/8" to 2 1/2"

- Capacity up to 625 liters/min (9900 gal/hr)

See this product in the Johnson Pump Marine Catalog: US ‖ GB ‖ DE ‖ ES ‖ FI ‖ SV

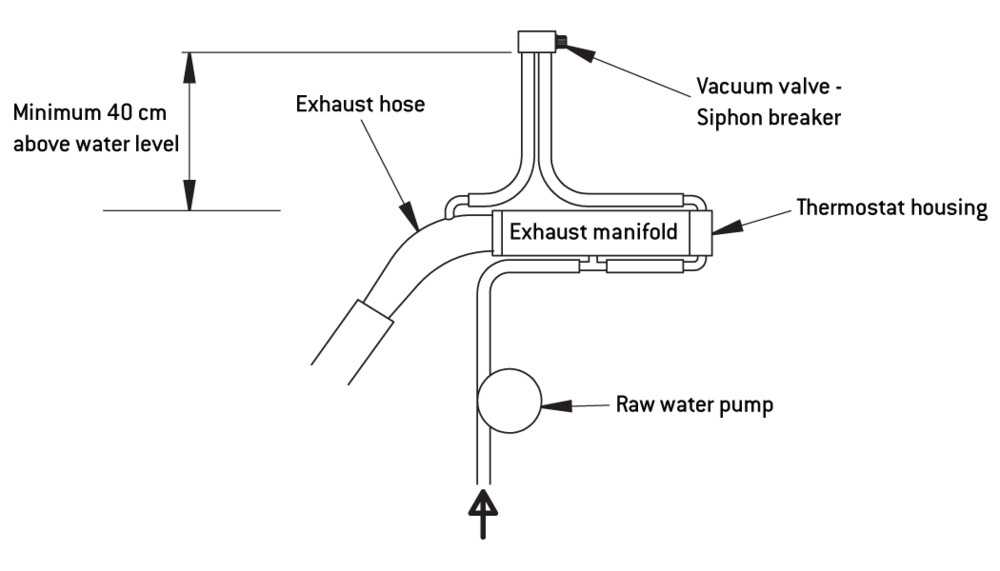

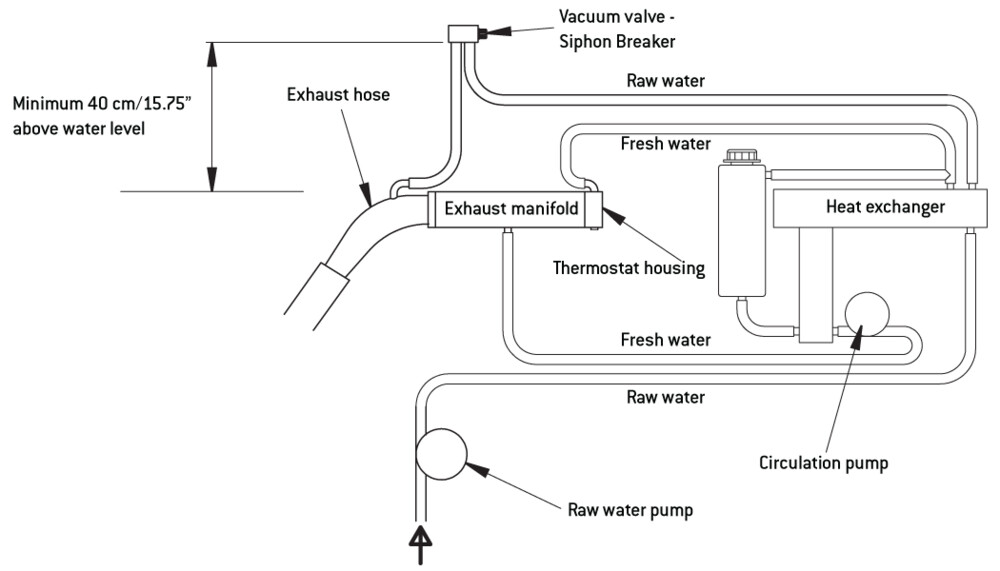

Engine Cooling – Raw Water Handling

Different Types of Cooling Systems

Fresh Water Handling

For circulation of the internal, closed, fresh water circuit of the cooling system SPX FLOW Johnson Pump can

offer a number of alternatives in its DC driven Circulation Pump series (see Circulation Pumps page).

It is also common to use a flexible impeller pump for this purpose if it is located on the cold side of the system

(max. 55°C/ 131°F ). Other types of belt-driven centrifugal pumps may also be useful. The closed circuit normally transfers heat from the engine to the heat exchanger. The liquid is a water and anti-freeze mixture.