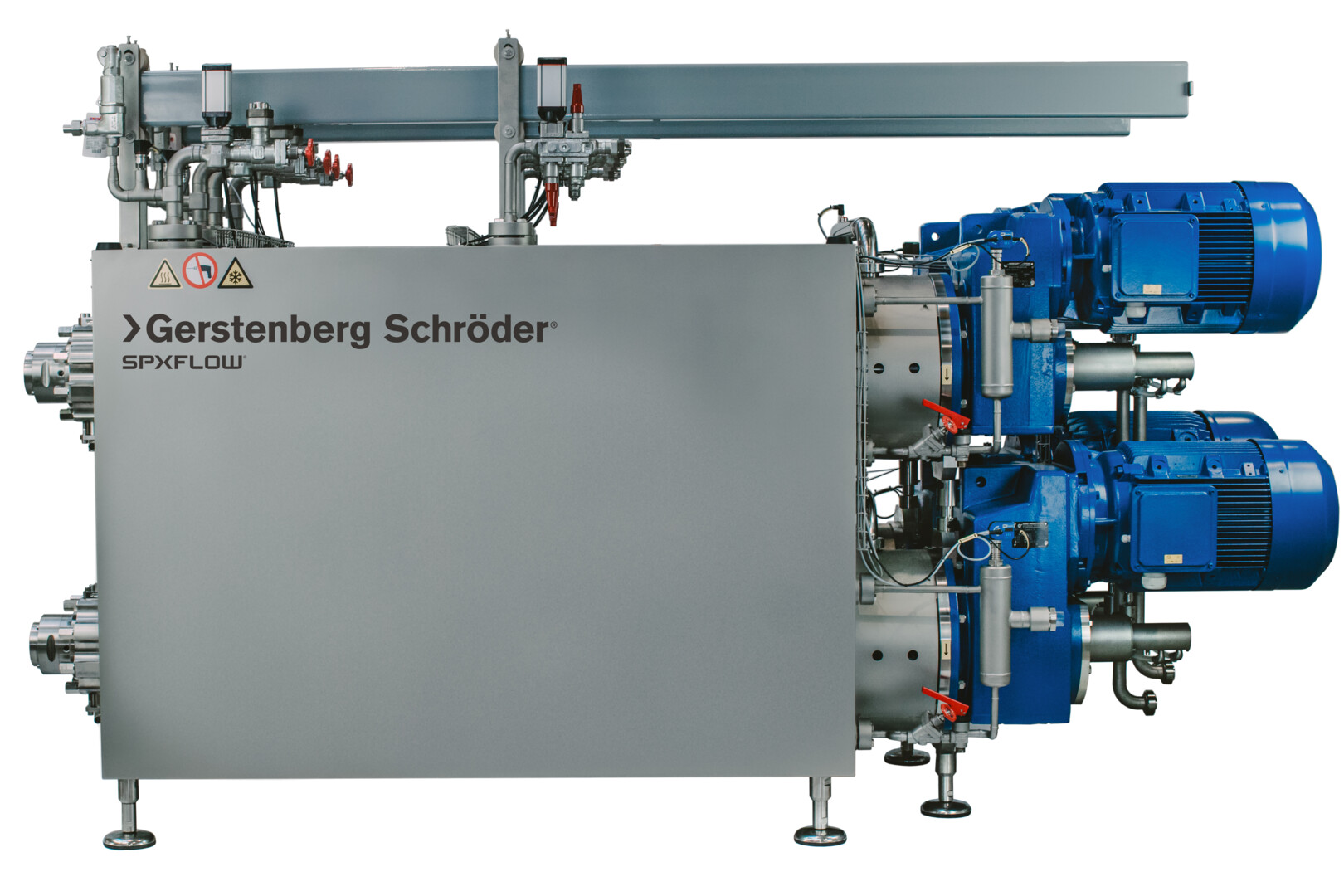

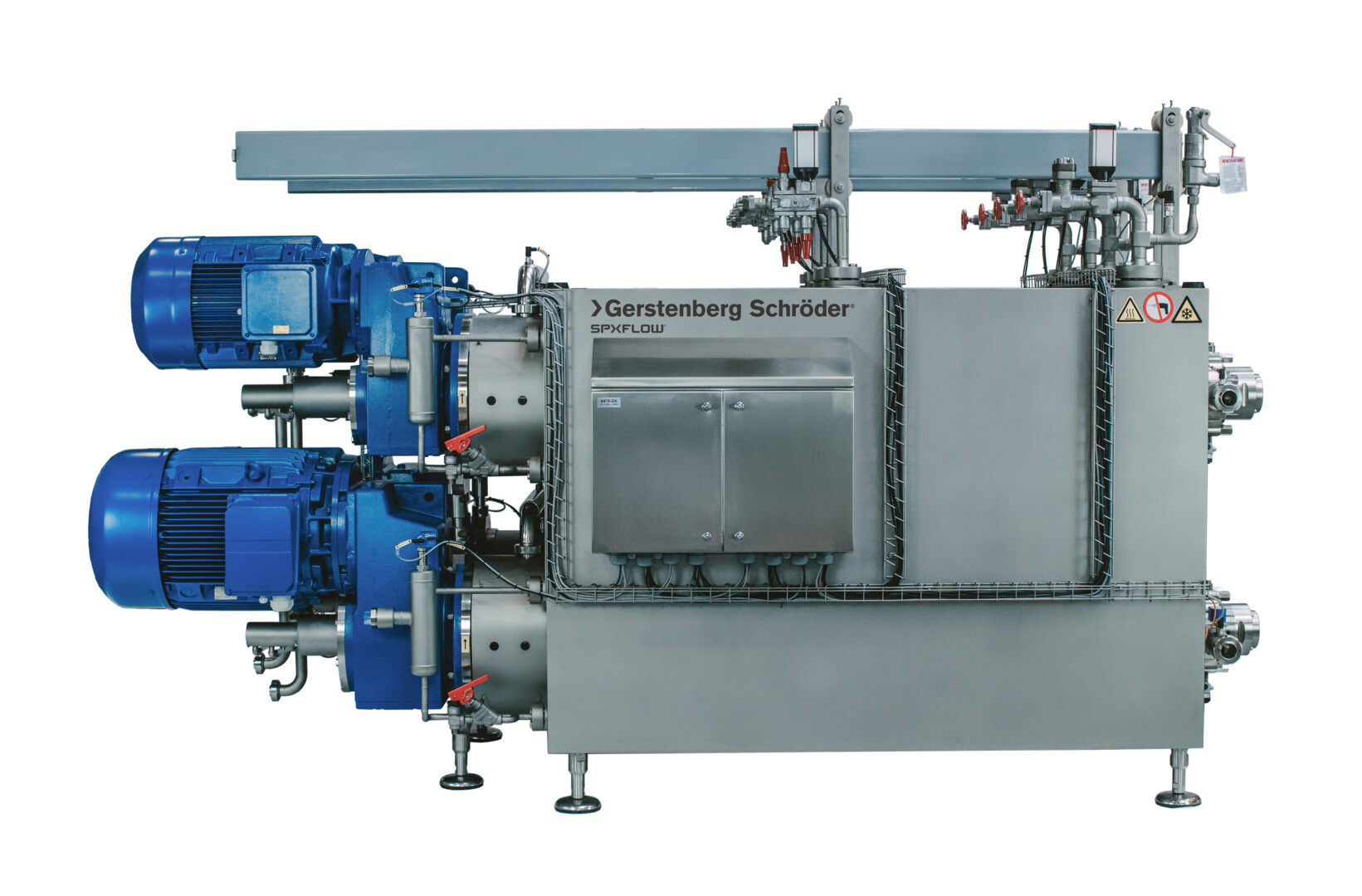

Nexus - Scraped Surface Heat Exchangers

Product Type(s) : Fat Crystalization Equipment

Description :

WHERE TO BUY

REQUEST PRICING

Nexus is a compact, high-capacity, high-pressure scraped surface heat exchanger designed for various high-viscosity applications within the Fats & Oils industry. It is designed for low energy consumption using CO2 as the highly efficient cooling medium, but it can also be used with the traditional ammonia NH3. It provides high crystallization performance, minimal downtime, and easy maintenance.

FEATURES

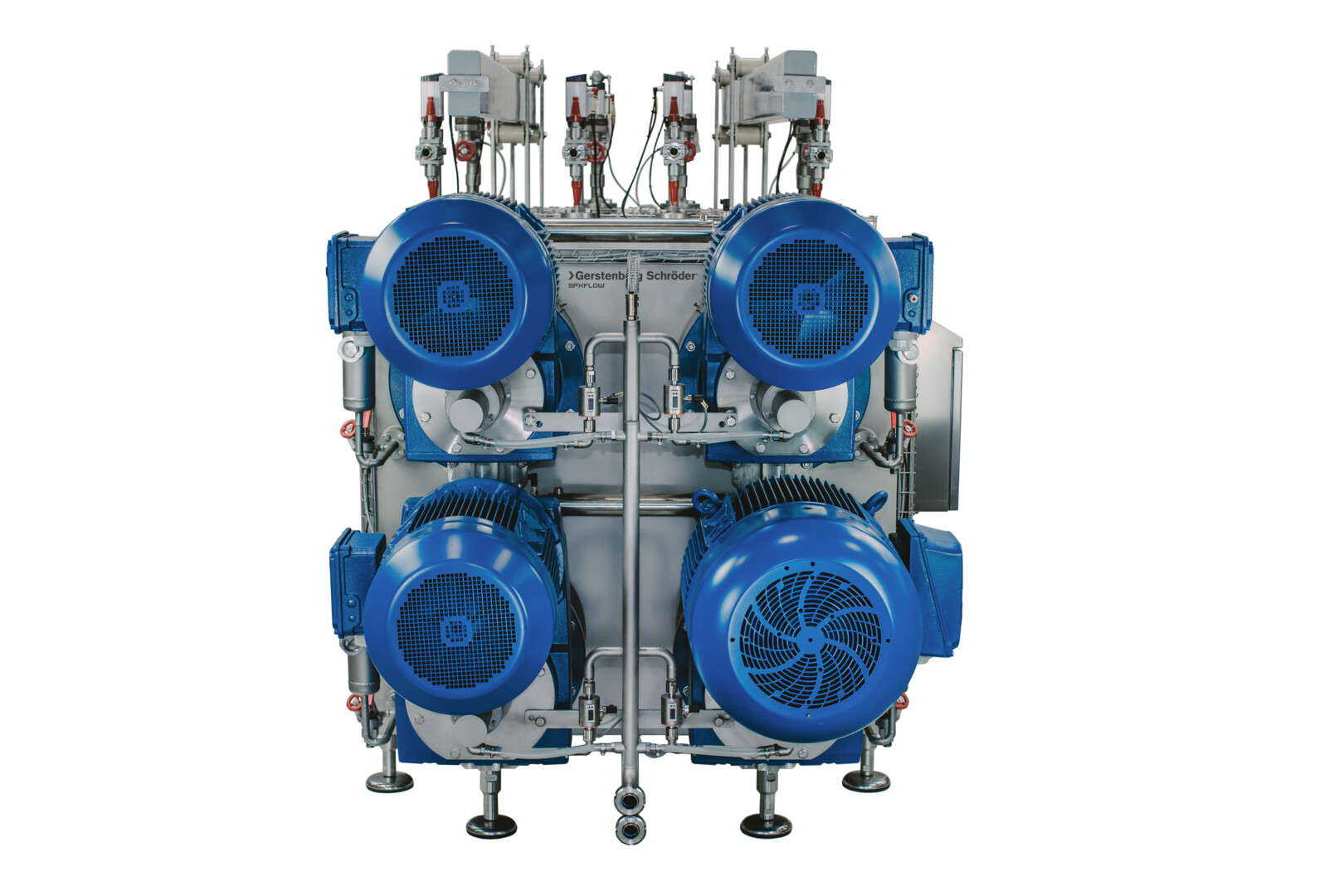

Nexus is designed to meet market demand for high-quality products combined with low-cost production. With Nexus you can produce the entire range of crystallizing Fats & Oils products, i.e., consumer margarine, industrial margarine, shortening, low-fat spreads, recombined butter and butter blends. Nexus consists of up to 4 chilling tubes, all equipped with individual cooling systems, and can be operated with CO2 or ammonia as the refrigerant. It was one of the first scraped surface heat exchangers to use the environmentally friendly CO2 as refrigerant. The advantage of CO2 over traditional ammonia (NH3) is the higher efficiency which results in more cost-efficient production. Should you choose ammonia initially, you can change the refrigerant to CO2 operation at a later stage. The design is robust, reliable, and built to last to meet our customers’ ever changing production requirements. Nexus complies with all major pressure vessel directives. Function and Principles of Operation Crystallization takes place in the scraped surface heat exchanger (SSHE) which is the heart of a Fats & Oils (F&O) crystallization line. The product is pumped into the chilling tubes where it is cooled and crystallized. Scrapers in the rotor system are then pressed against the chilling tube by constant centrifugal forces during rotation ensuring that the crystallized product is very efficiently scraped from the interior tube surface. Capacity up to 13.4 t/h

Benefits

- Multi-purpose machine for all edible Fats & Oils (F&O) products.

- Hygienic design suitable for the food industry.

- All product contacting parts are made in stainless steel AISI 316 or better.

- Completely sealed, fully insulated, corrosion-free stainless steel casing guarantees years of trouble-free operation.

- Special, corrugated multi-layer chromed chilling tubes for improved heat transmission value.

- The chilling tubes can easily be inspected and replaced.

- Optional rotor systems with scrapers in a selection of different materials depending on the application.

- Low energy production of crystallized fat products. Test results show that using CO2 at -10°C reduces energy consumption in the refrigeration system by up to 30% compared to an ammonia compressor at -20°C.

- Reduction in heat transfer costs. CO2 is a very efficient refrigerant which has an external heat transfer coefficient which is2-3 times higher than that of ammonia and which will increase the total heat flux by up to 40%.

- Heat recovery system possible. When using CO2 as the refrigerant, it is possible to install and use heat recovery systems to save energy. The heat recovery can offer useable water at up to 90°C, which can be used elsewhere in the plant. Up to 70% of the energy can be recovered.

- CO2 as refrigerant provides lower investment costs for CO2 refrigeration system compared with ammonia.

- Minimum downtime as CIP cycles are fast and efficient, and maintenance procedures are simple.

- The low energy motors and the cast iron gear boxes yield maximum power while keeping noise levels to a minimum.

- Small footprint which optimizes the floor space and the piping requirements.