Products

- Analyzers

- Automation Systems

- Butter Equipment

- Centrifuges

- Cleaning-in-Place Systems

- Deareators

- Draught Regulators

- Evaporators

- Fat Crystalization Equipment

- Filters & Strainers

- Fluid Bed Dryers

- Heat Exchangers

- Homogenizers

- Membrane Filtration Systems

- Microparticulation Systems

- Mixers & Agitators

- Pasturization Systems

- Pigging Systems

- Plumbing Products

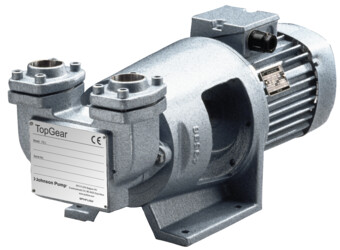

- Pumps

- Recreational Marine Products

- Recreational Marine Pumps

- Spin Flash Dryers

- Spray Dryers

- UHT Systems

- Valves

- Adhesives & Sealants

- Automotive Heating System

- Baby Food

- Bakery Filing Cream

- Beer, Cider, Wine & Spirits

- Biodiesel

- Boats & Watercraft

- Building Infrastructure

- Butter & Spreads

- Cement

- Cheese

- Chocolate

- Coffee & Tea

- Condiments, Sauces & Soups

- Cosmetics

- Dairy Powders

- Ethanol

- Flavors & Fragrances

- Fruit Juice

- Fuel Supply System

- Hair, Nail & Skin Care Products

- Ice Cream

- Inorganic Chemicals

- Margarine & Shortening

- Meat & Animal-Based Proteins

- Milk & Cream

- Neutralization

- Nutraceuticals

- Oral Care

- Paints & Coatings

- Petrochemicals

- Pipelines

- Plant-Based Food & Beverages

- Plastic & Resins

- Refinery

- Soft Drinks

- Solvents & Solutions

- Specialty Chemicals

- Synthetic Rubber

- Yogurt

Horticulture

Driving Innovation in the Horticulture Industry

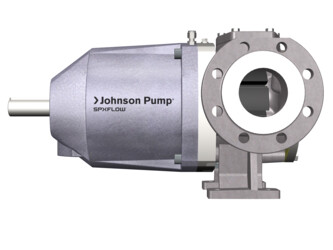

The horticulture industry is experiencing dynamic shifts in response to environmental challenges, regulatory demands and the need for efficient production practices. SPX FLOW, a leading innovator in fluid management, climate control and advanced mixing solutions, is uniquely positioned to support the horticulture sector’s objectives of increased productivity and sustainability. Our advanced centrifugal pumps, like the Johnson Pump® CombiLine and CombiBlocHorti, deliver unparalleled performance in managing greenhouse environments and optimizing irrigation.

With SPX FLOW, horticulture businesses gain access to an innovation center focused on automation, digitalization and resource efficiency, + which are essential for modern-day horticulture. Our products are meticulously designed for energy efficiency and operational reliability, supporting site managers, senior operations engineers and plant managers in driving both sustainability and cost-effectiveness across their facilities.

SPX FLOW’s commitment to the horticulture industry is reflected in our comprehensive service offerings and lifecycle cost management. By choosing SPX FLOW, horticulture leaders can trust in solutions that reduce maintenance needs, extend equipment longevity and promote safer, more sustainable operations.

Advanced Pump Technologies

-

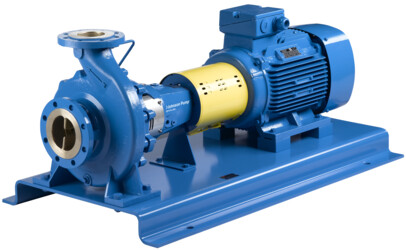

Johnson Pump CombiLine – Centrifugal Pump with In-line Ports:

Engineered for reliability and efficiency, the CombiLine pump supports critical fluid management processes within greenhouses. Its in-line ports facilitate seamless integration with various irrigation systems and climate control setups.Learn more

-

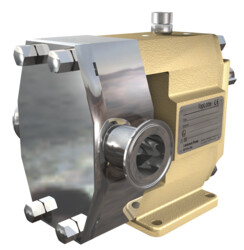

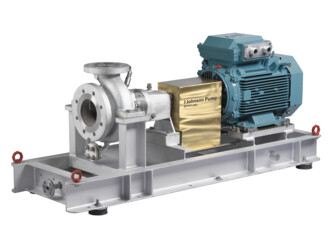

Johnson Pump CombiBlocHorti – Close-Coupled Centrifugal Pump:

Tailored for horticulture needs, the CombiBlocHorti pump excels in high-flow applications, ensuring consistent fluid delivery across large greenhouse spaces. Learn more.

Our pumps are proudly manufactured in Assen, Netherlands, located at the center of Europe’s horticulture innovation region, connecting our products to the forefront of industry advancements. Trusted across the horticulture sector, these pumps support sustainable practices, drive energy efficiency and enhance greenhouse operations.

Advanced Mixing Technologies

SPX FLOW also offers cutting-edge mixing solutions that support various stages of horticultural production, from fertilizer formulation to pesticide and fungicide safety. Our advanced mixers are engineered for the complex requirements of ingredient extraction, purification and conversion processes that meet both horticultural and regulatory standards. Key features of our mixing technologies include:

-

Fertilizer Manufacturing:

SPX FLOW's mixing solutions support every stage of the fertilizer production process, from extracting targeted ingredients to producing high-quality, intermediate or finished fertilizer products. Our agitators in beneficiary plants purify and qualify mined ingredients, while our reactor-based agitators reduce unplanned downtime, increasing annual production days. Additionally, our mixers extend the operational time between plant turnarounds and cleanouts, making them ideal for storage tanks and other high-use facilities.

-

Fungicide and Pesticide Production:

Safety and reliability are paramount when manufacturing fungicides and pesticides, given the hazardous nature of these chemicals in concentrated form. SPX FLOW’s proven agitation equipment minimizes the risks associated with producing these volatile substances, ensuring safe handling and consistent results. Our equipment’s robust design reduces the risk of leaks or accidental releases from pressurized tanks, offering peace of mind and operational reliability.

By enabling even nutrient distribution, optimizing ingredient consistency and promoting effective growth support, SPX FLOW’s mixing solutions help horticulture operators increase both crop yield and soil conservation efforts. Our solutions are also designed to support sustainability through minimized environmental impact and maximized resource efficiency.

Why Choose SPX FLOW?

SPX FLOW differentiates itself through a commitment to horticulture-specific innovations that improve efficiency, safety and cost-effectiveness. By investing in our technology, horticulture professionals benefit from:

-

Genuine Spare Parts and Service:

Ensuring optimal performance and extending the equipment lifecycle.

-

Sustainability and Efficiency:

Our products are designed to minimize environmental impact and reduce resource consumption.

-

Reliability and Safety:

Engineered to meet the rigorous demands of the horticulture industry, our solutions promote operational safety and consistent performance.

Call to Action:

Experience SPX FLOW’s commitment to horticulture. Contact us today to learn how we can help you achieve greater sustainability and productivity in your operations.

PRODUCTS

VIDEOS

How Greenhouse Climate Control Works: Inside a Dutch Research Center Boiler Room

FREQUENTLY ASKED HORTICULTURE QUESTIONS

Our advanced mixing technologies support fertilizer and pesticide formulation, enabling precise ingredient extraction, purification and consistent application. This helps improve soil health, increases productivity and supports sustainable horticulture practices.

SPX FLOW’s agitation equipment is designed to handle hazardous chemicals safely, reducing the risk of leaks or releases from pressurized tanks. This minimizes operational risks and supports safe handling practices for horticultural businesses.

When selecting an industrial mixer for fertilizer production, consider the following factors: 1.Material Characteristics: Evaluate properties of raw materials such as particle size, density and moisture content, which influence the mixer type and configuration. 2.Mixing Requirements: Determine the desired mixing intensity, duration and batch size to select a mixer that can meet specific production needs effectively. 3.Corrosion and Wear Resistance: Select a mixer built with corrosion-resistant materials to withstand exposure to fertilizers, which can be abrasive and corrosive over time. 4.Energy Efficiency and Operational Costs: Evaluate the mixer’s energy consumption and maintenance needs to ensure long-term cost-effectiveness.

Choosing the appropriate impeller design is essential for achieving efficient blending and uniform fertilizer consistency. Here’s a guide on available options and selection considerations: Impeller Options: 1.Flat-Blade Impellers: Recommended for low-viscosity or powder fertilizers, these impellers generate gentle flow, suitable for mixing without particle degradation. 2.Axial Flow Impellers: Useful for high-flow applications, axial impellers move material vertically, creating an efficient top-to-bottom mixing ideal for bulk blending of liquid fertilizers. 3.Radial Flow Impellers: Effective for applications requiring intense shear, radial impellers facilitate quick mixing and dispersal, ideal for handling granulated or multi-phase fertilizers. 4.Helical and Anchor Impellers: Suitable for high-viscosity materials, these impellers help scrape the vessel walls to prevent material buildup, ideal for handling sticky or thick fertilizer mixtures. Selection Criteria: 1.Material Characteristics: Consider particle size, density and moisture content to choose the mixer and impeller type that will best handle these properties without clogging or wear. 2.Desired Mixing Intensity: High-shear impellers are optimal for thorough blending of complex mixtures, while low-shear options are better for maintaining the integrity of fragile particles. 3.Batch Size and Production Speed: For large-scale continuous production, horizontal mixers with axial impellers may be most efficient. Smaller, batch-focused production often benefits from paddle or ribbon mixers. 4.Compatibility with Corrosive Materials: Select impeller and mixer materials that are resistant to corrosion to handle fertilizer components that may be abrasive or reactive over time.

The Johnson Pump® CombiLine Centrifugal Pump is expertly designed for the horticulture industry, providing reliable fluid management and precise climate control essential for maintaining optimal growing conditions within greenhouses. Manufactured in Assen, Netherlands, at the heart of Europe’s horticulture innovation region, the CombiLine is closely aligned with cutting-edge industry advancements. Key benefits include: 1.Consistent Temperature and Humidity Control: The CombiLine efficiently circulates heated water from boilers, distributing even temperature and humidity levels across the greenhouse, which supports stable, year-round plant growth. 2.Energy Efficiency and Reliability: Renowned for its high efficiency and low energy consumption, the CombiLine reduces operational costs while its robust design minimizes downtime, making it ideal for continuous use. 3.Low Maintenance: Built with fewer moving parts and corrosion-resistant materials, the CombiLine pump is low-maintenance, enhancing reliability, reducing service costs and maximizing productivity. 4.Versatile Integration: Adaptable to various heating sources—including boilers, solar thermal systems and heat pumps—the CombiLine offers flexible, energy-efficient climate control options tailored to specific greenhouse needs. 5.Customizable Capacity: Available in sizes and capacities suited to different greenhouse scales, the CombiLine meets specific flow rate and heating requirements, making it effective for both small-scale and industrial operations. 6.Quick Rebuild Capability: Featuring a convenient pull-out unit for rapid motor and pump rebuilds, the CombiLine minimizes downtime and ensures seamless, efficient operations. The Johnson Pump CombiLine Centrifugal Pump is a versatile and reliable solution trusted across the horticulture sector to support sustainable practices, enhance operational efficiency, and drive energy savings, ultimately maximizing productivity and reducing environmental impact in greenhouse environments.