Evaporation and Drying Solutions for Diverse Industries

Anhydro's cutting-edge evaporation and drying equipment is designed to meet the diverse needs of industries such as dairy, food and beverage, pharmaceuticals and chemicals. Our advanced solutions support liquid concentration and powder processing for a wide variety of substances from milk to batteries.

Advanced Drying Technology

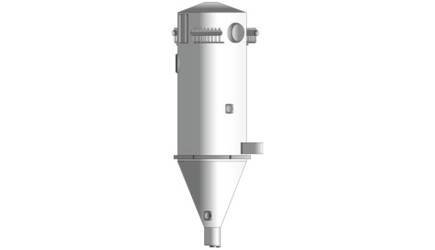

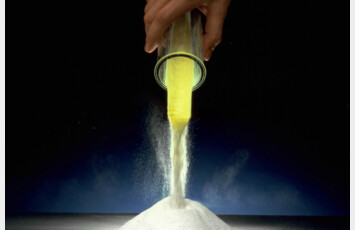

Our proprietary, energy-efficient drying systems—including spray dryers, fluid bed dryers, spin flash dyers and small-scale dryers—excel in even the most demanding liquid applications to be dried into powder. They ensure consistent granularity and moisture levels while preserving critical product attributes such as color, flavor and aroma.

Attend the Anhydro Flavour Seminar

Join industry leaders at the Anhydro Flavour Seminar to master spray drying plant design and best practices.

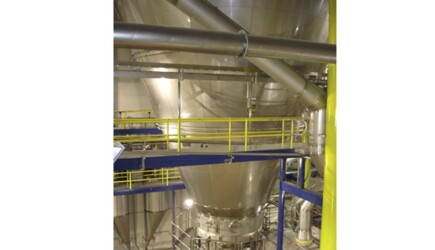

High-Performance Evaporators

Anhydro’s falling film and forced circulation evaporators are essential for extending product shelf life and reducing volume for cost-effective transportation. Their automated process control features enable full traceability, ensuring product integrity and minimizing the risk of recalls

Comprehensive Support and Service

With a dedicated technical team and state-of-the-art testing facilities, we provide services that enhance equipment performance and longevity. By optimizing productivity, conserving energy and minimizing maintenance costs, our solutions help customers achieve operational excellence. Contact us today.

Choose Anhydro for reliable, efficient and innovative evaporation and drying solutions to optimize your processes and protect your bottom line.

Where to Buy

SPX FLOW Technology Danmark A/S

Oestmarken 7

2860 Soeborg

Denmark

Phone: +45 70 278 222

Email: ft.dk.soeborg@spxflow.com

PRODUCTS

DOWNLOADS

VIDEOS

BlueLight Whitening System®

Customer Testimonial: InLeit

SmartDry™ System

Customized, End-to-End Process

Anhydro Evaporators

SUPPORT

NEWS & EVENTS

BLOG POST

SPX FLOW First Year Care Program

NEWS RELEASE

Streamlining Seasonal Shutdowns: SPX FLOW Ensures Operational Continuity

EVENT

Anhydro Flavour Seminar

Blog: Solutions in the Making

Spray Dryers

Sustainable and Cost-Effective Lactose Whitening

Lactose powder requires whitening to meet standards. Traditional methods include carbon cartridges and lactose washing, but we provide a new, sustainable alternative.

READ MORE

The Top Four Reasons to Upgrade Your Spray Dryer

When's the last time you upgraded your spray dryer system? We found producers spend 20% of their time cleaning plants, and time is money. Let us help.

READ MORE

Evaporators

Anhydro Celebrates 75 Years of Spraying Magic

Anhydro is recognizing its 75-year anniversary this year. As experts in atomization excellence, join us in celebrating the magic of spray dryers worldwide.

READ MORE