Products

- Analyzers

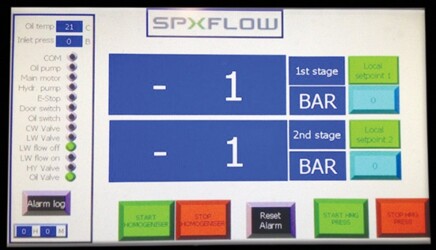

- Automation Systems

- Butter Equipment

- Centrifuges

- Cleaning-in-Place Systems

- Deareators

- Draught Regulators

- Evaporators

- Fat Crystalization Equipment

- Filters & Strainers

- Fluid Bed Dryers

- Heat Exchangers

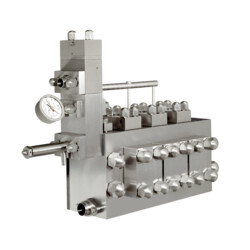

- Homogenizers

- Membrane Filtration Systems

- Microparticulation Systems

- Mixers & Agitators

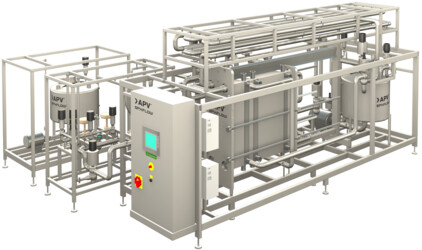

- Pasturization Systems

- Pigging Systems

- Plumbing Products

- Pumps

- Recreational Marine Products

- Recreational Marine Pumps

- Spin Flash Dryers

- Spray Dryers

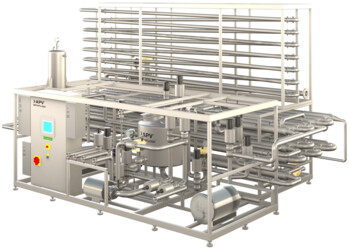

- UHT Systems

- Valves

- Adhesives & Sealants

- Automotive Heating System

- Baby Food

- Bakery Filing Cream

- Beer, Cider, Wine & Spirits

- Biodiesel

- Boats & Watercraft

- Building Infrastructure

- Butter & Spreads

- Cement

- Cheese

- Chocolate

- Coffee & Tea

- Condiments, Sauces & Soups

- Cosmetics

- Dairy Powders

- Ethanol

- Flavors & Fragrances

- Fruit Juice

- Fuel Supply System

- Hair, Nail & Skin Care Products

- Ice Cream

- Inorganic Chemicals

- Margarine & Shortening

- Meat & Animal-Based Proteins

- Milk & Cream

- Neutralization

- Nutraceuticals

- Oral Care

- Paints & Coatings

- Petrochemicals

- Pipelines

- Plant-Based Food & Beverages

- Plastic & Resins

- Refinery

- Soft Drinks

- Solvents & Solutions

- Specialty Chemicals

- Synthetic Rubber

- Yogurt

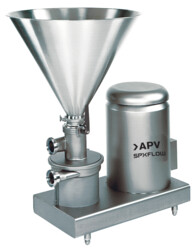

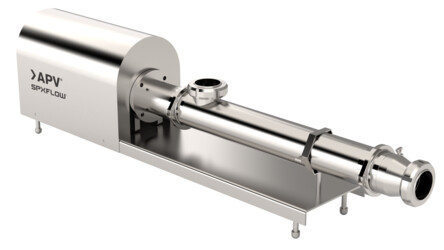

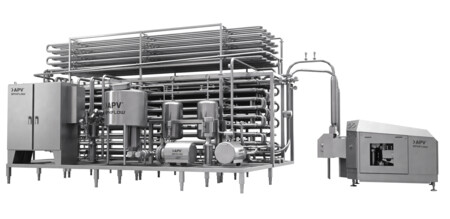

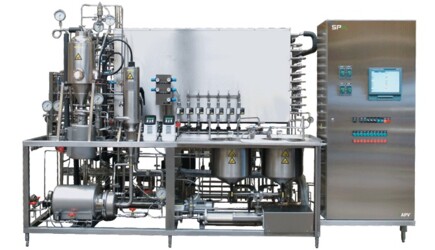

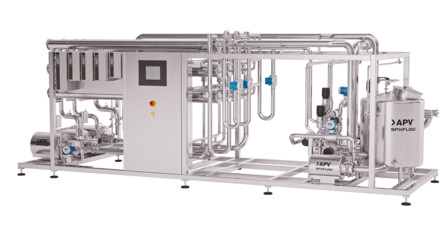

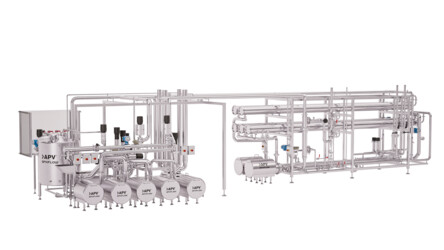

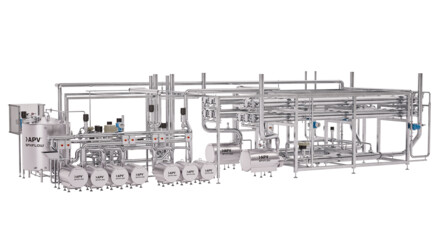

APV, an established centennial engineering legacy, is an important part of the SPX FLOW brand, integrated over a decade ago. Addressing the food/beverage, dairy, pharmaceutical and healthcare markets, APV offers highly effective turnkey automation and process engineering solutions. These industrial solutions combine the extensive array of heat exchangers (for evaporation, pasteurization and UHT), pumps (rotary, centrifugal, inducer, etc.), valves, mixers, dissolvers and homogenizers that we manufacture with numerous services which will maximize the effectiveness of systems throughout the whole of their life-cycle. These services cover original system inception, equipment deployment, upgrades and eventual decommissioning, as well as plant optimization. APV industrial process solutions are leaders in operational performance and consistency. Beyond performance, APV aftermarket services are integrated to establish safety and efficiency.

PRODUCTS

.

WHERE TO BUY

Downloads

SUPPORT

US Office

SPX FLOW, Inc.

611 Sugar Creek Road

Delavan, WI 53115 USA

Customer Service: 1-262-728-1900 or 1-800-252-5200

Email: DelavanCS@spxflow.com

Related Support: Pumps, Valves, Homogenizers, Dispersion, Scraped Surface Heat Exchangers, Mixers

SPX FLOW, Inc.

105 Cross Point Pkwy

Getzville, NY 14068 USA

Phone: 1-716-692-3000 or 1-800-828-7391

Related Support: Thermal Processing / Heat Transfer Systems, FX Systems, Evaporation / Distillation Systems, Mixing and Blending Systems

Chile Office

Mexico Office

Colombia Office

SPX LATIN AMERICA CORPORATION COLOMBIAN BRANCH

Calle 113 7-45 Torre B Oficina 1018

110111 Bogotá, Colombia

Phone: +57 (601) 746-4565 , +1 (800) 252-5200

Email: cs.latam@spxflow.com

Related Support: For US phone Number, choose Option 8

Brazil office

SPX Flow Technology do Brasil Comércio e Participações Ltda.

Alameda Terracota, 250 – Sala 802

Cerâmica | São Caetano do Sul |

CEP 09531-190, SP, Brasil

Phone: +55 11 2127-8278 , +1 (800) 252-5200

Email: cs.latam@spxflow.com

Related Support: For US phone Number, choose Option 9

Belgium Office

SPX FLOW Europe Ltd - Belgium Branch

Evenbroekveld 6

B-9420 Erpe Mere

Phone: +32 (0) 53 60 27 80

Email: Customerservicebe@spxflow.com

Contact us

Related Support: Industrial Heat Exchangers, Systems

Czech Republic Office

SPX FLOW Technology s.r.o.

Holandská 1006/10

CZ-Brno 63900

Phone: +420 516 800 800

Related Support: Systems

Denmark Office

SPX FLOW Technology Danmark A/S

Pasteursvej 1

DK-8600 Silkeborg

Phone: +45 70 278 278

Email: FT.Nordic.Aftermarket@spxflow.com

Related Support: Thermal Processing, Heat Transfer Systems, Mixing and Blending Systems, Pumps, Valves, Homogenizers, Innovation Centre

France Office

SPX Flow Technology SAS

Zone Industrielle No 2

290 rue Jacquard

FR-27006 Evreux Cedex

Phone: +33232237309

Email: Customerservicefrance@spxflow.com

Related Support: Systems

Germany Office

SPX Flow Technology Germany GmbH

Gottlieb-Daimler-Straße 13

59439 Holzwickede

Germany

Phone:+494052202001

Email: dortmund.sc@spxflow.com

Related Support: Industrial Heat Exchangers, Systems

Hungary Office

SPX FLOW Technology Hungary Kft.

Vegyész u. 17-25

H-1116 Budapest

Phone: +36 12 27 44 96

Related Support: Industrial Heat Exchangers, Systems

Ireland Office

SPX FLOW Europe Ltd – Ireland Branch

Unit 73 Dunboyne Business Park, Dunboyne, Co Meath

Ireland

Phone: +353 1 6966 201

Email: Customerserviceire@spxflow.com

Italy Office

SPX FLOW Technology Italia S.p.A.

Via Ambrosoli, 1 Localita, Millpini Rodano

Franz. Millepini

I-20090 Milan

Phone: +39 0445 010036

Email: Customerserviceitaly@spxflow.com

Related Support: Systems

Netherlands Office

SPX FLOW Europe Ltd - The Netherlands

A.F. Philipsweg 51

NL-9403AD Assen

Phone: +31592711399

Email: CustomerserviceNL@spxflow.com

Related Support: Industrial Heat Exchangers, Systems

Poland Office

SPX FLOW Technology Poland Sp. z o.o.

Office in Warsaw

ul. Zabłocka 10

PL-03-194 Warszawa

Phone: +48 22 504 1810

Email: ft.warszawa.office@spxflow.com

Related Support: Systems

Pumps, Valves, Homogenizers, Mixers,Hygienic Heat Exchangers

Spare Parts, Technical Service

Poland Office

Industrial Heat Exchangers

SPX FLOW Technology Poland Sp. z o.o.

Gdańsk

Poland

Phone: +48 58 343 01 98

Email: ft.gdansk.office@spxflow.com

Related Support: Industrial Heat Exchangers

Saudi Arabia Office

APV MIDDLE EAST Ltd.

P.O. Box 4259 Riyadh 11491

Sulaimaniya – King Abdulaziz Road

Kingdom of Saudi Arabia

Phone +966 11 4775208

Related Support: Industrial Heat Exchangers, Systems

South Africa Office

SPX FLOW Technology (Pty) Ltd Africa

Unit 12B

Growthpoint Office Park, Tonetti Street

Midrand

South Africa

Phone: +27 11 207 370

Fax: +27 11 207 3707

Email: customerservicejnb@spxflow.com

Related Support: Systems, AM & OE

Spain Office

SPX FLOW EUROPE LTD. Sucursal en España

C/ Albasanz, 12 – 4º Izquierda

28037 Madrid

Phone: +34 913049040

Related Support: Industrial Heat Exchangers, Systems

United Arab Emirates Office

SPX FLOW Technology

P.O.Box 299745

Downtown Jebel Ali,

The Galleries 4,

Dubai, United Arab Emirates

Phone: +971 4 814 3400

Related Support: Industrial Heat Exchangers, Systems

Australia Office

SPX Flow Technology Australia Pty Ltd

211 Atlantic Drive, Keysborough

Victoria, 3170

Australia

Phone: +61 (0) 39589 9222

SPX Flow Technology Australia Pty Ltd

Quad 2 6 Parkview Drive

Sydney Olympic Park, NSW, 2127

Australia

Phone: +61 (0) 2 9763 4900

SPX Flow Technology Australia Pty Ltd

121 Links Avenue South

Eagle Farm, Queensland 4009

Australia

Phone: +61 (0) 7 3630 6200

SPX Flow Technology Australia Pty Ltd

46 Callaway Street

Wangara, WA 6065

Australia

Phone: 61 8 6102 3008

Greater China Office

SPX (Shanghai) Flow Technology Co., Ltd. – Beijing

22F, Tower A, Gateway Plaza, No.18 Xiaguangli, East 3rd Ring North Rd.

Chaoyang District, Beijing 100027, P.R. China

Phone: +86 10 5926 7000

Email: Email: ft.cn.cs@spxflow.com, china.contact@spxflow.com

SPX (Shanghai) Flow Technology Co., Ltd. – Chengdu

Room 601, Building A, No. 3 Gaopeng Road

Gaoxin District, Chengdu China

Phone: +86 28 8517 3256

Email: ft.cn.cs@spxflow.com, china.contact@spxflow.com

SPX (Shanghai) Flow Technology Co., Ltd. – Shanghai

6th floor, No.1568, Huashan Road, Changning, shanghai China

Phone: +86 21 2208 5888

Fax: +86 21 2208 5680

Email: ft.cn.cs@spxflow.com, china.contact@spxflow.com

SPX (Shanghai) Flow Technology Co., Ltd. – Shanghai Xidu Plant

Fengjin Road No.666

Nanqiao Zhen, Fengxian, Shanghai China

Phone: +86 21 6715 8181

Fax: +86 21 6715 8282

Shanghai PHE Service Center

Phone: 400 152 8008/8621 2208 5888

Email: ft.cn.cs@spxflow.com, china.contact@spxflow.com

SPX Flow Technology Hong Kong Limited, Taiwan Branch

9th Floor, No.26, Alley 513, Ruiguang Road

Neihu, Taipei China

Phone: +886 28797 3324

Email: ft.cn.cs@spxflow.com, china.contact@spxflow.com

India Office

SPX FLOW Technology, India - Pune

SPX FLOW Technology (India) Pvt. Ltd.

Survey no. 236 & 237, RGIP, Phase I, Phase - II Road,

Hinjewadi, Pune,

Phone: +91 78 78492145, +91 20 67499964

Email: CS.NHSA@SPXFLOW.COM

Japan Office

SPX Flow Technology Japan, Inc. – Tokyo

Unosawa Tokyu Bldg. 2F, 1-19-15 Ebisu

Shibuya-Ku, Tokyo 150-0013 Japan

Phone: +81-3-5793-5611

Email: ft.jp.customerservice@spxflow.com

Singapore Office

SPX Flow Technology Singapore Pte Ltd.

20 Pioneer Crescent #06-01

West Park BizCentral

Singapore 628555

Customer Service/Tech support: +65 6870 2027, +65 8123 4755

Email: CS.NHSA@SPXFLOW.COM

Notes: Handles Korea and Vietnam as well

Thailand Office

SPX Flow Technology (Thailand) Limited - Bangkok

Bangkok Business Center Building, Unit 2702,

29 Sukhumvit 63 Road, Klongton Nua, Wattana,

Bangkok 10110, Thailand

Phone: +66 2 7143838, +66 86-078 6832

Email: CS.NHSA@SPXFLOW.COM

NEWS & EVENTS

BLOG POST

A Smarter, Steam-Free Solution: How Cavitation Is Transforming Spray Dryer Feed Heating and Centrifugal Atomizer Performance

NEWS RELEASE

Streamlining Seasonal Shutdowns: SPX FLOW Ensures Operational Continuity

![[DISCONTINUED] DA3+ Series - Double Seat Mixproof Valves](https://www.spxflow.com/assets/three-column-block/apv-valves-double-seat-da3plus.jpg)