Products

- Analyzers

- Automation Systems

- Butter Equipment

- Centrifuges

- Cleaning-in-Place Systems

- Deareators

- Draught Regulators

- Evaporators

- Fat Crystalization Equipment

- Filters & Strainers

- Fluid Bed Dryers

- Heat Exchangers

- Homogenizers

- Membrane Filtration Systems

- Microparticulation Systems

- Mixers & Agitators

- Pasturization Systems

- Pigging Systems

- Plumbing Products

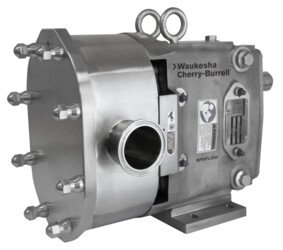

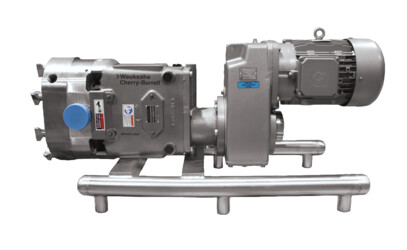

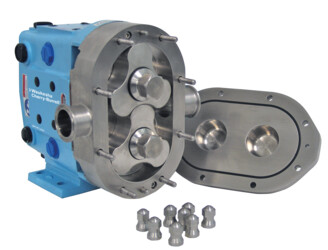

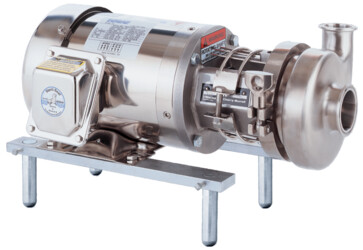

- Pumps

- Recreational Marine Products

- Recreational Marine Pumps

- Spin Flash Dryers

- Spray Dryers

- UHT Systems

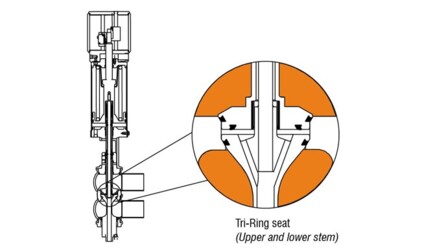

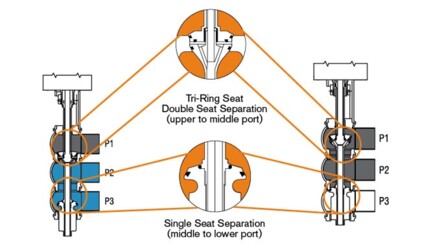

- Valves

- Adhesives & Sealants

- Automotive Heating System

- Baby Food

- Bakery Filing Cream

- Beer, Cider, Wine & Spirits

- Biodiesel

- Boats & Watercraft

- Building Infrastructure

- Butter & Spreads

- Cement

- Cheese

- Chocolate

- Coffee & Tea

- Condiments, Sauces & Soups

- Cosmetics

- Dairy Powders

- Ethanol

- Flavors & Fragrances

- Fruit Juice

- Fuel Supply System

- Hair, Nail & Skin Care Products

- Ice Cream

- Inorganic Chemicals

- Margarine & Shortening

- Meat & Animal-Based Proteins

- Milk & Cream

- Neutralization

- Nutraceuticals

- Oral Care

- Paints & Coatings

- Petrochemicals

- Pipelines

- Plant-Based Food & Beverages

- Plastic & Resins

- Refinery

- Soft Drinks

- Solvents & Solutions

- Specialty Chemicals

- Synthetic Rubber

- Yogurt

Pharmaceutical

Pharmaceutical Manufacturing with SPX FLOW

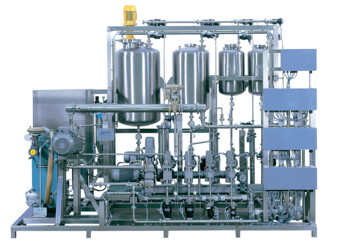

Industrial Pharmaceutical Production Equipment

SPX FLOW develops dedicated mixing and heat transfer systems for the pharmaceutical processing industry. Leveraging over a century of experience, a global network of research and development centers, and a dedicated staff of knowledgably application engineers, to develop highly specialized pharmaceutical processes.

Customized Pharmaceutical Equipment

Pharmaceutical Processing Equipment

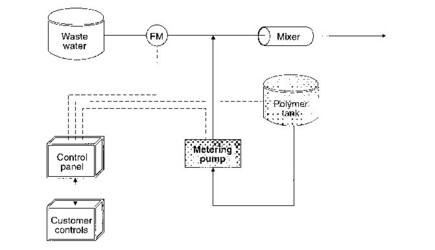

Mixing Equipment

Manufacturing in the pharmaceutical processing industry is predicated on the effective production of sterile medicinal products. Sanitation is vital to pharmaceutical production and processing, restricting the type of mixers used to air driven and electric mixers primarily. Mixers capable of fully mixing pharmaceuticals is highly depended on by the pharmaceutical processing industry. To create a standard of quality each product must be well blended, requiring a mixer based on the environmental variants of the pharmaceutical production line, to best evenly blend the individual product components. SPX FLOW offers specialized mixer design, to custom design a mixer to the customer’s needs. SPX FLOW’s global mixing lab in Rochester, New York, is a scientific testing environment where SPX FLOW brands Lightnin and Plenty utilize state-of-the-art predictive technologies to explore mixing solutions.

Pharmaceutical Applications: Mixing

- vaccine production

- antibiotics

- mammalian cell cultures

- blood factors

- injectables

- buffer solutions

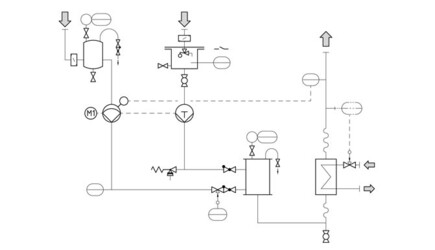

Heat Transfer Equipment

SPX FLOW develops and manufactures custom heat transfer systems for the pharmaceutical processing industry. SPX FLOW designs custom fit heat exchangers by first understanding the specifics of the product and customer needs. Developing heat exchanger systems with dedicated sanitary standards requires a depth of technical and industry experience. SPX FLOW process engineers leverage decades of industry experience and a network of global test labs to build calibrated heat exchanger applications. Our innovation and design centers located in Shanghai, China; Silkebog, Denmark; and Mamirolle, France, feature a testing lab to for exploitative problem solving and application development.

Pharmaceutical Applications: Heat Exchangers

- Antibiotic broths

- Culture media sterilizers

- Sterile water

- Cosmetics

- Shampoos

- Conditioners

- Creams

- Mouth washes

- Mineral and baby oils

- Starches