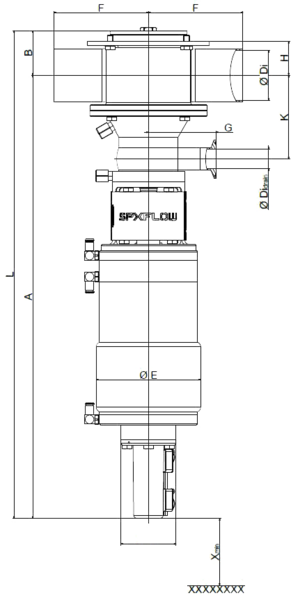

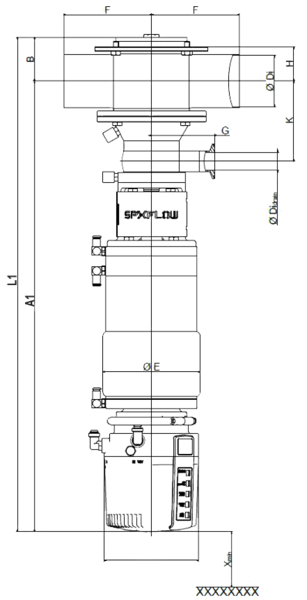

DT4 Series - Tank Outlet Double Seat Mixproof Valves

Product Type(s) : Tank Outlet Valves

Description :

WHERE TO BUY

The DT4 tank outlet mix proof valve is used for the reliable separation between the tank and servicing pipeline. The DT4 tank outlet is an extension to the D4 Series mix proof family which helps fulfil today’s customer demands for production flexibility, increased productivity, rapid return on investment (ROI) and improved product quality in the food and drink, dairy, personal care and brewing process industries.

FEATURES

High value, Low life cycle costs:

- “All-In” standard features such as seat lift actuator and cross-port housing provide exceptional value

- Reduced inventory costs with same seal kit used on multiple size ranges: DN40-DN65 (1.5”-3.0”) and DN80-DN100 (4.0”)

- Low air consumption and air supply requirements

- Leak drain with clamp connection for CIP fluid collection

- Long housing ports ease manifold building

- Integrated shaft seal flush reduces need for external piping

Reliable performance:

- Design based on the proven D4SL model

- Tank side holding pressure greater than 5 bar (73 PSI)

- Long stroke for gentle product handling (ex: particulates) and low flow resistance

- Balanced design helps to prevent hydraulic blocking and enables flexible flow direction without slamming

- Heavy-duty bolted flange connection between tank/housing/insert provides secure, controlled assembly/disassembly of valve insert

- No compressed air needed for removal and servicing

- Range of control units and bus communication for automated operation

Cleanability:

- Designed to the latest global hygienic standards

- Cavity spray cleaning as standard

- Radial seal design provides minimal switching leakage

- Extensive cleaning of product contact seals

View the SPXFLOW D4 Mix Proof Valve Maintenance (Chinese) video.