Flex-Mix™ Pilot Mixer

Flexibility to test mixing products from low to high viscosity in small batch sizes. Ideal for recipe development and small batch production.

FEATURES

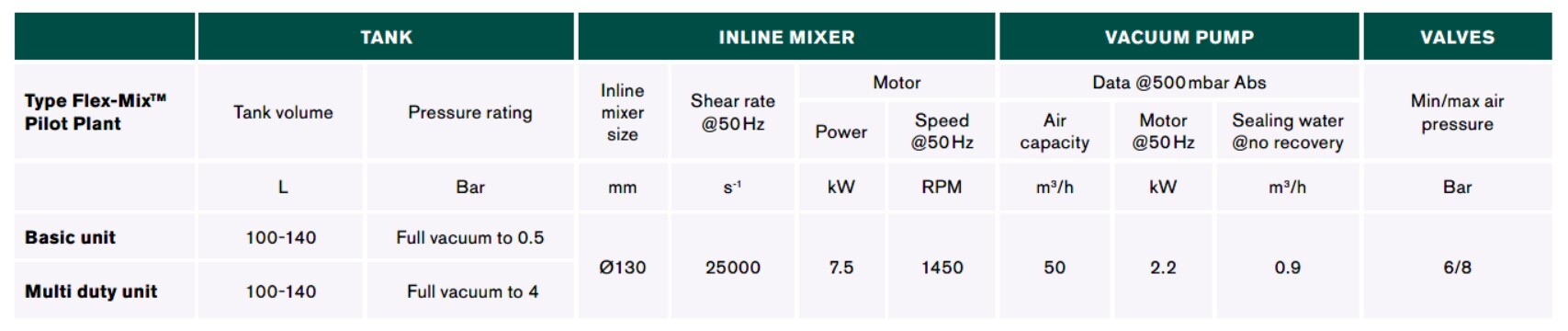

The Flex-Mix™ Pilot is a flexible, skid-mounted mixer specifically designed for high shear mixing via the rotor/stator principle. It features the flexibility to test a wide range of products from low to high viscosity in a small batches. It’s efficient, improves speed to market, and because it’s from SPX FLOW, you know it’s reliable.

Available either to rent or purchase, the Flex-Mix Pilot enables you to perform high-shear mixing and blending in your own labs to replicate actual process conditions. These in-house tests provide a clear direction to whether products and recipes can be replicated on a larger scale which translates to more efficiency by not having to shut down an active line for testing.

Flex-Mix Pilot mixer comes equipped with all the features of a full-scale mixer, including heating jackets, agitators, scrapers and semi-automation systems. It performs three types of testing - mixing, direct heating and jacket heating and cooling.

The range of ingredients that can be tested in the Flex-Mix Pilot include liquids, dry powders, soluble pastes, coarse grinds and solids.

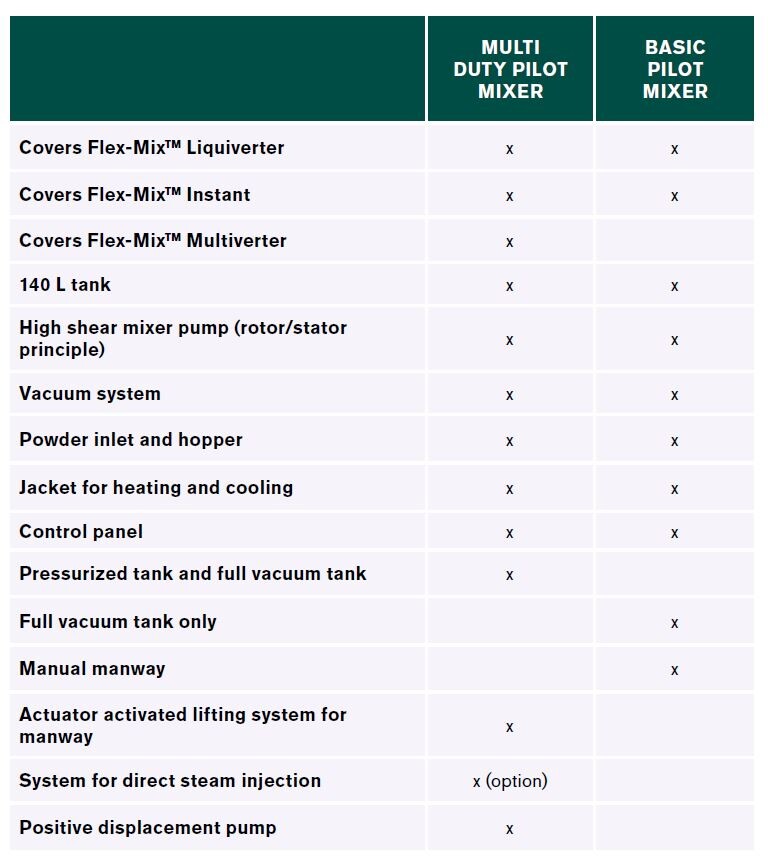

This pilot mixer now enables customers to test in just one unit the three different types of mixing techniques available in the full scale APV Flex-Mix™ series:

- Atmospheric mixing for low viscosity products like ice cream mix and recombined dairy products. It used internal recirculation and scales up to our Flex-Mix™ Liquiverter mixer.

- Vacuum-mixing for low viscosity products like infant formula and plant based products. It uses external recirculation and scales up to our Flex-Mix™ Instant mixer.

- All in one mixing with or without vacuum or heating for medium and high viscous products like processed cheese and meat products. It uses internal recirculation and scales up to our Flex-Mix™ Multiverter mixer.

The Flex-Mix™ Pilot Mixer is especially suitable for product formulations requiring a wide range of ingredients including liquids, dry powders, soluble pastes, coarse grinds, and solids.

Typical applications include

- Mixing of products with low and medium/high viscosities

- Operating under vacuum/atmospheric pressure for incorporation of dry or semi solids into liquid

- Chopping of solids

- Heating/cooling of blended products

- Dispersion

- Reconstitution

- Rehydration

- Re-establishment of soluble products