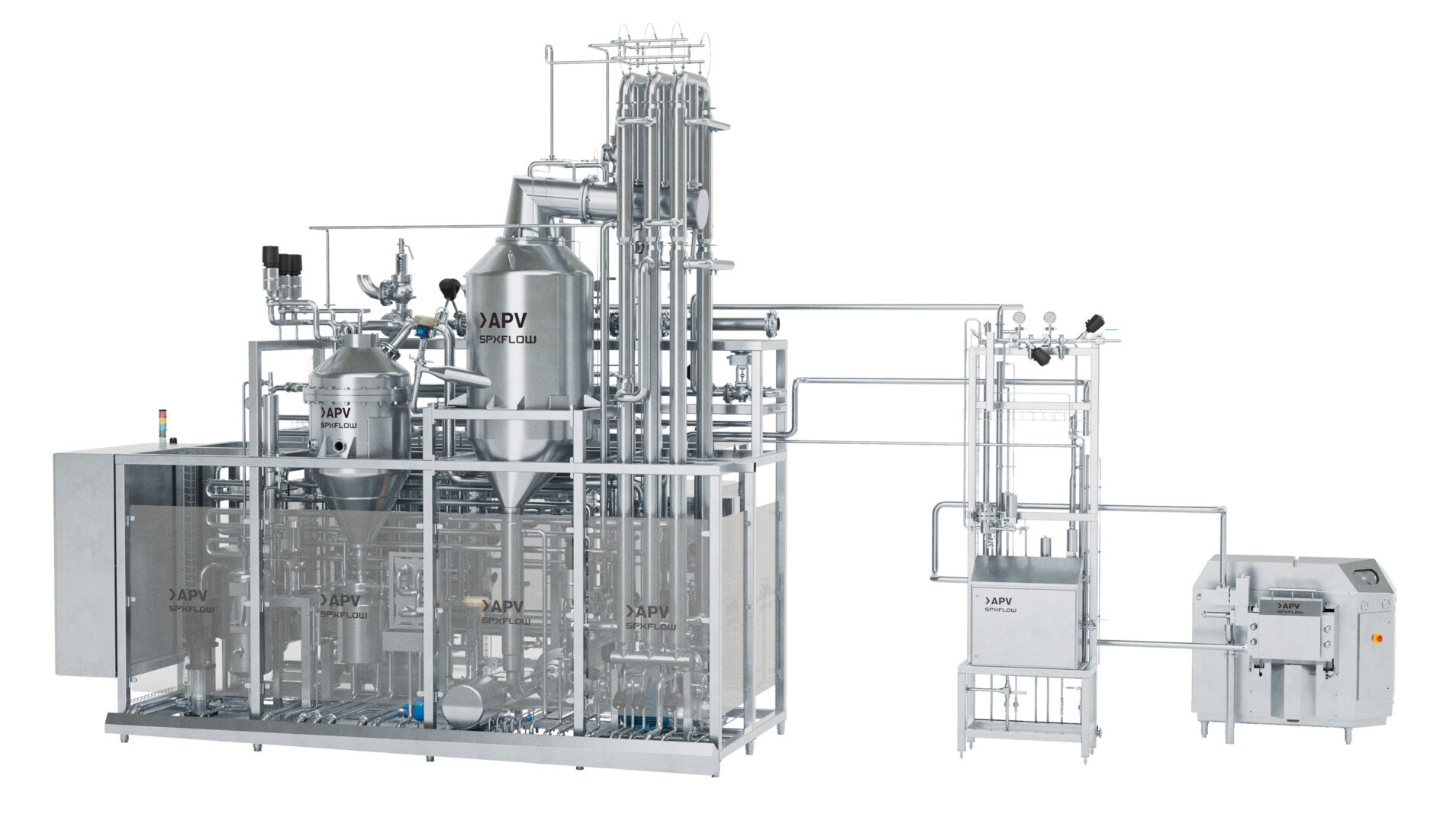

Infusion UHT Systems

The APV® Infusion UHT Systems are designed to deliver premium-quality aseptic and extended shelf life (ESL) products with minimal thermal impact through direct steam infusion. Using gentle, rapid heating and cooling with precise holding times, these systems ensure superior product integrity while preserving natural flavors, textures and nutrients. Engineered for dairy, plant-based beverages and high-protein applications, APV® Infusion UHT technology achieves fresh, pasteurized-like taste while extending shelf stability equal or better than standard HTST processed milk