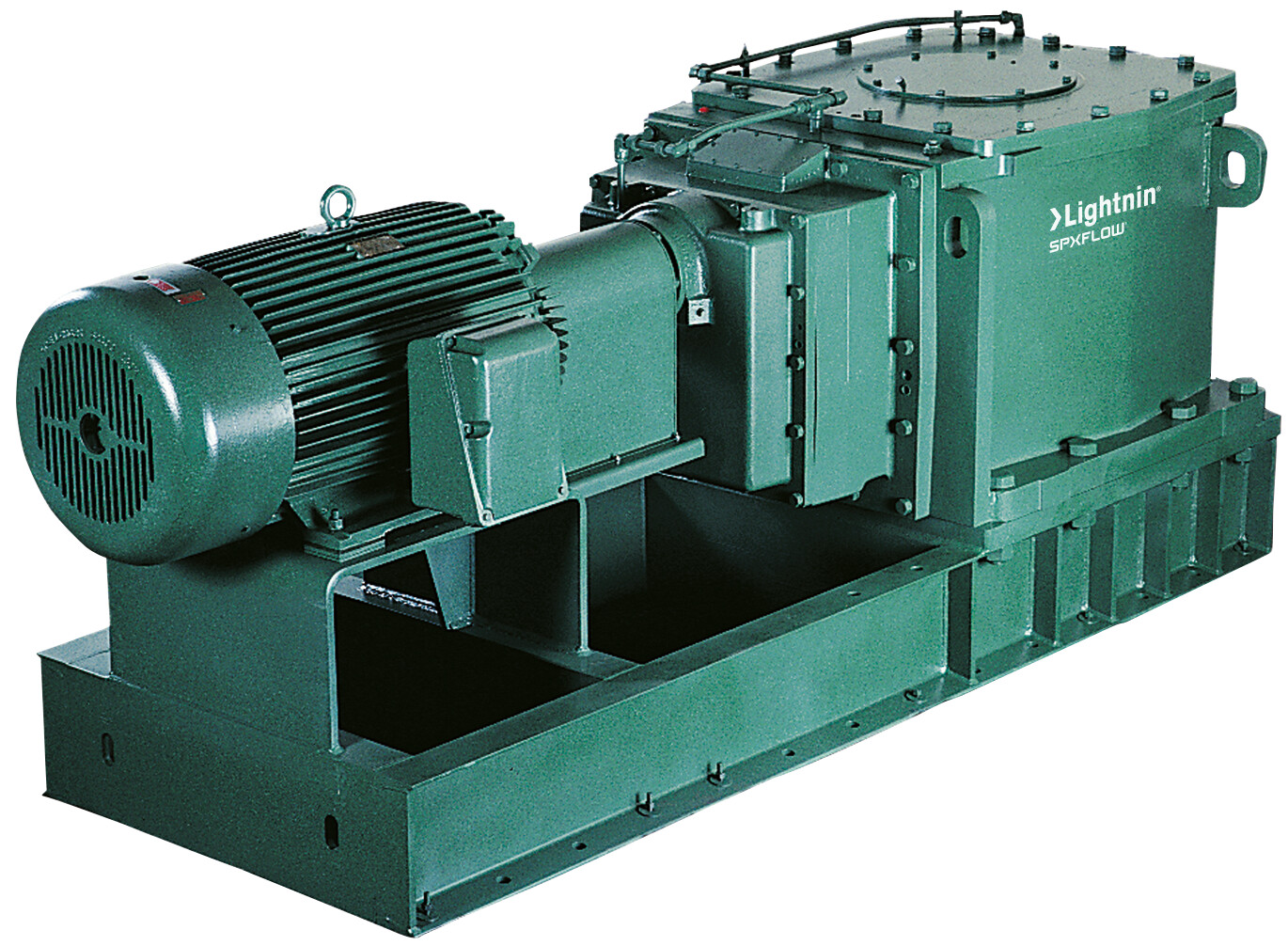

700/800 Series - High Torque Top Entering Mixer

Lightnin 700/800 Mixers are designed to provide reliable service in the largest, most demanding applications, from pharmaceutical fermentation and large-scale chemical processing to minerals processing and heavy sludge waste treatment.

FEATURES

PRODUCT FEATURES AND BENEFITS

- Exclusive hollow quill drive protects the gear train from severe shaft flexure.

- Bearings are sized far beyond AGMA requirements for minimum maintenance and long service life

- Heavy-duty motor mount is standard

- Horsepowers from 25 to 3000 + and speeds from 230 to 11.4 rpm

- Choice of replaceable cartridge seals

- Largest output shaft per allowable torque for greater bending design & longer shafts.

- Case carburized & ground helical-bevel combination gearing for unmatched efficiency, quiet running & long life

Full Spectrum of Impellers to Optimize Results: Included are the A310 for flow-controlled applications, the A320 for high-viscosity requirements, the A315 for handling gas alone or gas and solids together, as well as the A6000 for applications requiring the special benefits of composite construction. Guaranteed Performance: Together, we design your rugged 700/800 mixer, selecting impeller type, shaft length and other specifications to optimize process results. Then, we guarantee your Lightnin Mixer to perform the job for which it is recommended. Tested 100%: Every large Lightnin mixer drive is tested under load on an advanced dynamometer. Test check gear contact patterns, noise readings, thermal data and lubrication. We welcome you to watch us test your mixer. Our goal always: Deliver factory-assembled, ready-to-go packaged units with interchangeable parts that will provide you the most efficient performance at the best possible cost. New design for 784/884 Mixers

- Positive direct drive

- Rugged housing designed for easy assembly and maintenance

- Tapered roller bearings handle overhung shaft loads

- Triple reduction gearing has robust AGMA service factor

- Available on larger units to 1250 hp

Features available on units up to 1000kW (1250HP) Flex ProtectionGears in all 800 series units like this one are protected from mixer shaft bending loads by the Lightnin hollow quill flex protection. Quill and shaft mixer are mounted on separate bearings. A torsionally resilient coupling transmits power from quill to mixer shaft, while isolating gearing from shaft flex. Splash LubricationOn sizes up to 783/883, gears dipping in an oil sump provide a constant flow of oil to all surfaces. Covered For SafetyPersonnel are protected from rotating parts by guards that meet OSHA requirements.All mounting flanges are designed to ASME Unfired Pressure Vessel Code. Rugged Motor MountA heavy-duty channel base is the standard motor mount for Series 700/800. Oil DamLeakage down the mixer shaft is positively prevented by an oil dam around the quill shaft. Quiet-Running GearsAll helical gears are carburized and ground. The highly efficient spiral bevel gear and pinion are match-lapped as a set to assure smooth, quiet operation.