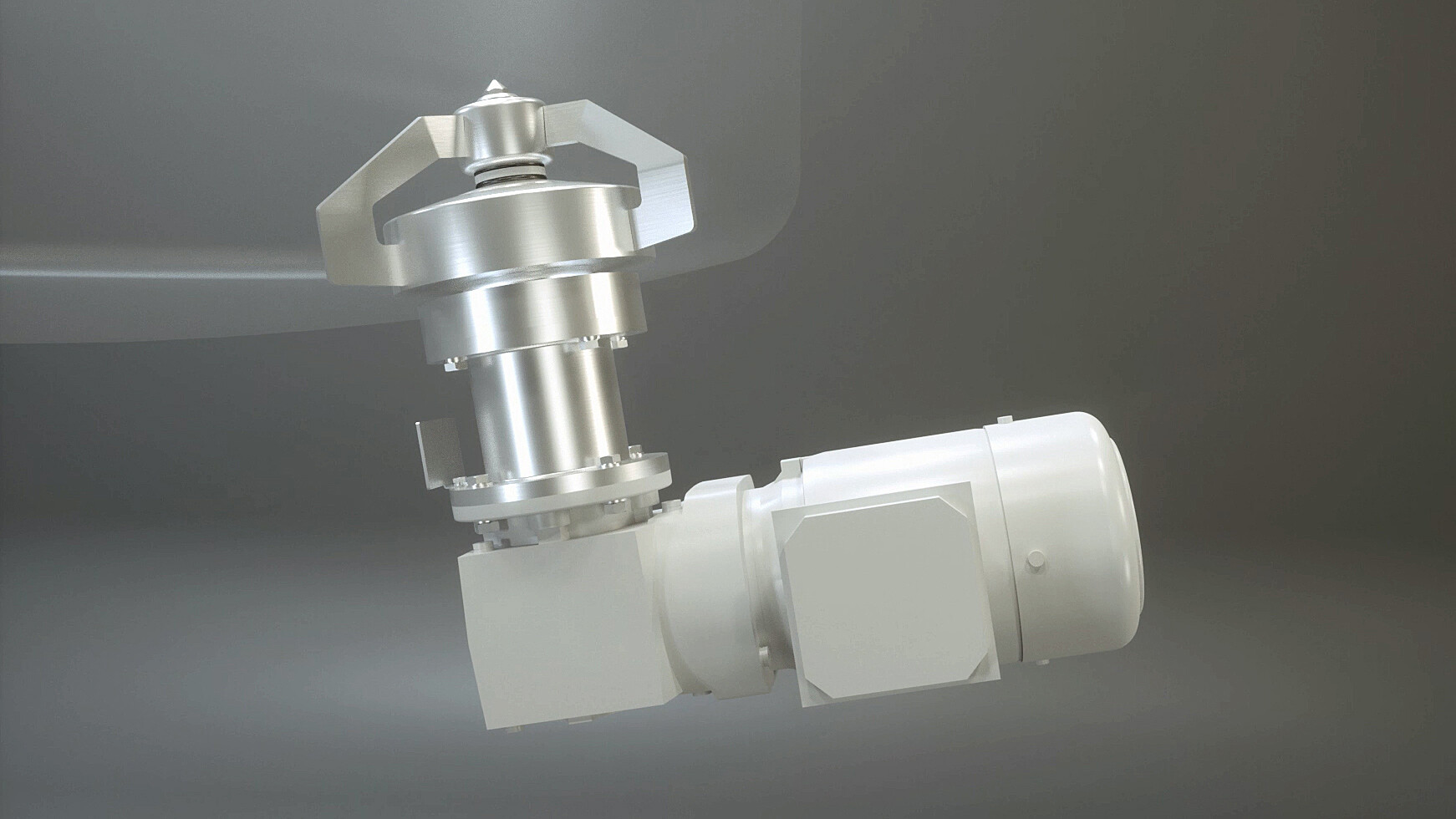

MagMixer MBE Series Bottom Entry Mag Mixer

The Lightnin bottom-entry MagMixer® MBE prevents contamination in pharmaceutical and biotechnology processing and storage applications. It offers a wide power range to suit small or large tank volumes.

FEATURES

Lightnin – MBE MagMixer® The MBE Series mixers are suitable for blending, dissolving solids and solid suspension making them suitable for use in Pharmaceutical, Bio-technology, Food & Beverage and Home Care & Personal Care applications. Your mixing performance remains unchanged as you still have access to the key Lightnin impellers that serve your applications.

- Wide power range 0.09kW to 7.5kW (0.12Hp to 7.5Hp) making the MBE suitable for a wide range of applications and tank volumes up to 50,000L (13,200 Usgal)

- High bearing gap and lift design to allow product to pass through and lubricate the sleeve bearing. CIP and SIP are easily achieved.

- High torque co-axial magnetic coupling with decoupling mechanism on large sizes

- All in-tank materials meet USP Class VI standards

- Fully SIP or CIP by flooding or spray ball

- Can be run dry for complete drainage during Clean in Place (CIP) cycles

- Gear-motor with variable speed capability

- FDA compliant Food-grade Epoxy paint

- 316SS wetted parts polished and electro-polished to 0.5mRa (20µinRa) as standard or better on request. High alloys available.

- Available with Lightnin's QAD validation support package

Design Features & Functions of Bottom-Mounted Magnetic Agitators BEARINGS

- Zirconium oxide inner bearing: less risk of breakage, resistant to damage by sudden settling of the rotor

- Silicon carbide outer bearing: with channels in the face side for better lubrication of the bottom contact surface and enhanced cleaning (CIP)

- Run-dry capability with the rotor type MBE: Magnetic lifting of the impeller reduces the load on the bearing surface so that the agitator can be kept running while the vessel is emptied (mixing down to the last drop)

LOWERING DEVICE Agitators size from MBE200 and upwards are supplied with a special lowering mechanism that withdraws the drive magnet out of the containment shell. BENEFITS OF THE RETRACTABLE DRIVE MAGNET Controlled removal and safe insertion of the impeller due to withdrawl of the drive magnet. The drive unit remains in position while the magnetic drive rotor is lowered out of the containment shell. Avoids damage to the ceramic bearings. Improved safety: The device protects against the crushing hazard involved in placing the agitator head on the bearing, and thus meets the demand of the EC Machinery Directive for designed protection against injury. REMOVABLE CONTAINMENT SHELL (PLUG-IN) As an alternative to a version with a flange for welding into the vessel, the agitator can be supplied with a removable containment shell. This can facilitate maintenance. This practical Plug-In solution is becoming more popular and makes it easier to switch from shaft-driven agitators with mechanical seals to magnetic agitators. ELECTROPOLISHING OF STAINLESS STEEL SURFACES As well as mechanical polishing to two levels, we also electropolish as standard so that we can meet the growing demand for the highest possible surface quality.