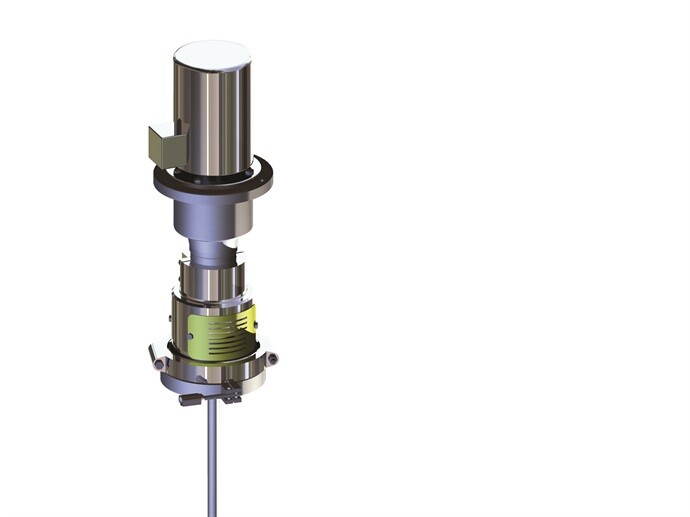

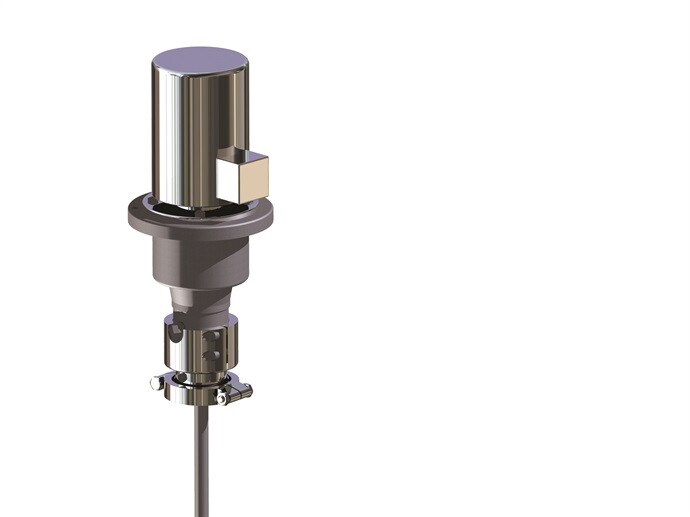

Nettco S-Series - Small Portable Mixer

Sanitary Stainless Steel Portable and Fixed Mount Mixers configured to meet your sanitary needs. Available in a wide range of mixing and mounting configurations utilizing a unique modular assembly design.

FEATURES

The Nettco S-Series sanitary mixer is available in a wide range of mixing and configurations utilizing a unique modular assembly design. With one mixer it is possible to configure a clamp-on, open tank, or sealed mixer design. This mixer can be quickly converted from one mounting arrangement to another. Modifying the mounting configuration can be accomplished in less than two minutes. Modular Design

- Sanitary, all stainless steel design

- 304 SS housing -Washdown (IP55), inverter ready motor

- Proven planetary gearing – robust and reliable

- Food grade lubricant

- Unique, innovative modular design

- Reverse-taper shaft attachment for added safety

- Stainless Steel Motor, 0.37 - 2.2 Kw (1/2 - 3 HP)

- Optional air motor available

-

- Fully standardized product

- Direct and gear options for this global use mixer provides full range of shaft speeds (RPM)

-

- 1450, 290, and 240 (50 Hz)

- 1750, 350, and 280 (60 Hz)

- Shaft lengths up to 2100 mm (84”)

- Simple, compact design, 3A and EC 1935:2004 clean design available

- Economical

- Impellers from world’s mixing technology leader

-

- Multiple style impellers available

- Hydrofoil, PBT and FP 100 (Marine Props)

Nettco Temperature Limits

- Ambient temperature limits

- Min 32F (0 C)

- Max 104 F (40 C)

- In-tank temperature limits

- Model P & Q Max 200 F (93 C)

- Model L Max 300 F (150 C)

- Model S Max 250 F (121 C)

Typical Product Applications

With an all stainless steel construction and features designed to meet 3-A and EC1935:2004 standards, the Nettco S-Series mixer can be used in a variety of sanitary mixing applications. And with Lightnin’s unparalleled experience, every mixer comes with a process guarantee!