Products

- Analyzers

- Automation Systems

- Butter Equipment

- Centrifuges

- Cleaning-in-Place Systems

- Deareators

- Draught Regulators

- Evaporators

- Fat Crystalization Equipment

- Filters & Strainers

- Fluid Bed Dryers

- Heat Exchangers

- Homogenizers

- Membrane Filtration Systems

- Microparticulation Systems

- Mixers & Agitators

- Pasturization Systems

- Pigging Systems

- Plumbing Products

- Pumps

- Recreational Marine Products

- Recreational Marine Pumps

- Spin Flash Dryers

- Spray Dryers

- UHT Systems

- Valves

- Adhesives & Sealants

- Automotive Heating System

- Baby Food

- Bakery Filing Cream

- Beer, Cider, Wine & Spirits

- Biodiesel

- Boats & Watercraft

- Building Infrastructure

- Butter & Spreads

- Cement

- Cheese

- Chocolate

- Coffee & Tea

- Condiments, Sauces & Soups

- Cosmetics

- Dairy Powders

- Ethanol

- Flavors & Fragrances

- Fruit Juice

- Fuel Supply System

- Hair, Nail & Skin Care Products

- Ice Cream

- Inorganic Chemicals

- Margarine & Shortening

- Meat & Animal-Based Proteins

- Milk & Cream

- Neutralization

- Nutraceuticals

- Oral Care

- Paints & Coatings

- Petrochemicals

- Pipelines

- Plant-Based Food & Beverages

- Plastic & Resins

- Refinery

- Soft Drinks

- Solvents & Solutions

- Specialty Chemicals

- Synthetic Rubber

- Yogurt

WR60 / WR80 Series - Over-Pressure Relief - Single Seat Valves

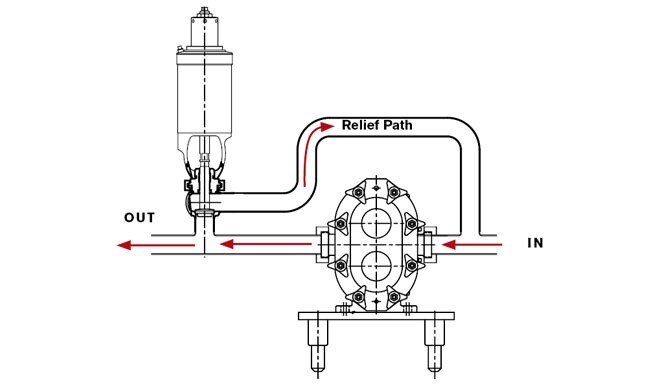

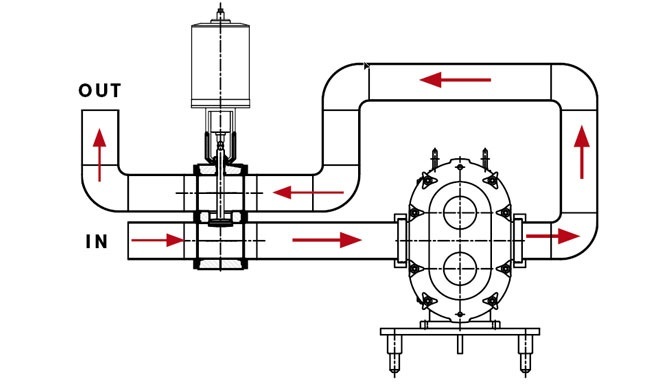

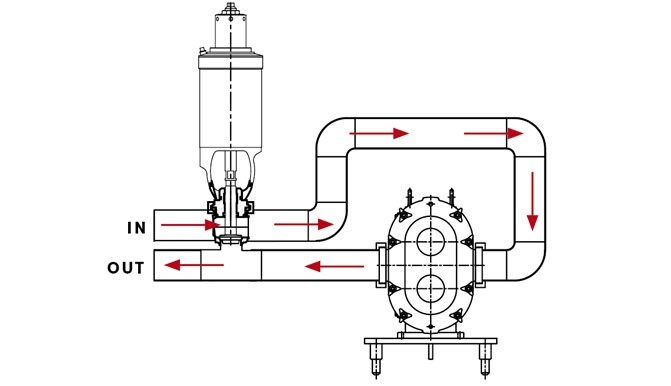

The WR60 / WR80 adjustable pressure relief valve or pressure safety valve allows users to set the desired relief cracking pressure right at the valve by simply turning the adjustment screw. Installing a pressure-relief valve can protect pumps in a process line by allowing the pump to discharge pressure if it exceeds the cracking pressure set on the valve.

FEATURES

Protect your pump with an external over-pressure relief valve. If pump discharge pressure exceeds the set cracking-pressure, the valve will open to a relief path. The adjustable-spring actuator allows users to set the desired relief cracking pressure right at the valve by simply turning the adjustment screw. The relief pressure setting can be bypassed to completely open the valve for CIP cleaning without over-pressuring the valve and pipeline. Features and Benefits:

- Utilizes standard W60/W80 single seat components offering machined-from bar bodies, modular design, Tef-Flow™ P stems, and low cost of ownership.

- Adjustable-spring, maintenance-free actuator allows easy setting of desired relief cracking pressure.

- Actuator piston bypasses relief pressure setting and fully opens valve for CIP cleaning without need to over-pressurize the valve and pipeline.

- Multiple body styles provide minimal dead-leg relief configurations with pump for efficient cleaning and processing.

- Various controls options available on valve for feedback and automation.

- W80 stem flush adapter available for aseptic applications.

Product Specifications

Materials:

Product Wetted: ASTM 316L (UNS-S31603); (DIN-1.4404)

Non-Product: ASTM 304 (UNS-S30400); (DIN-1.4301)

Seat Material: Tef-FlowTM P (Std.) and metal (Optional) for strength and durability

Elastomers: FKM or EPDM

Finish: < 32Ra (<0.8 µm) Other finishes available upon request

Sizes: Available in three actuator diameters, 4” (102mm), 5” (127mm) and 6” (152mm) with heavy springs for these series and sizes:

- WR61 air-to-raise valves (AR) 1.5” (38mm) – 4” (102mm)

- WR63 air-to-lower (AL) 2” (51mm) -4” (102mm)

Pressure Ratings:

Standard

| Valve Size with Pressure at | 1.0" / 1.5" (25 / 38 mm) |

2.0" (51 mm) |

2.5" (64 mm) | 3.0" (76 mm) | 4.0" (101 mm) | 6.0"* (152 mm) |

|---|---|---|---|---|---|---|

| 70ºF (20ºC) |

500 psi | 450 psi | 400 psi | 350 psi | 200 psi | 150 psi |

| (34.5 bar) | (31 bar) | (28 bar) | (24 bar) | (14 bar) | (10 bar) | |

| 160/180ºF (71/82ºC) |

375 psi | 350 psi | 300 psi | 250 psi | 150 psi | 100 psi |

| (26 bar) | (24 bar) | (17 bar) | (17 bar) | (10 bar) | (6 bar) | |

| 250ºF (121ºC) |

250 psi | 250 psi | 200 psi | 150 psi | 125 psi | 75 psi |

| (17 bar) | (17 bar) | (14 bar) | (10 bar) | (8 bar) | (5 bar) |

Valve with High Pressure Adapter and Clamps

| Valve Size with Pressure at | 1.0" / 1.5" (25 / 38 mm) |

2.0" (51 mm) |

2.5" (64 mm) | 3.0" (76 mm) | 4.0" (101 mm) | 6.0" (152 mm) |

|---|---|---|---|---|---|---|

| 70ºF (20ºC) |

1220 psi | 300 psi | 720 psi | -- | -- | -- |

| (84 bar) | (62 bar) | (49 bar) | -- | -- | -- | |

| 160/180ºF (71/82ºC) |

1160 psi | 855 psi | 690 psi | -- | -- | -- |

| (80 bar) | (60 bar) | (47 bar) | -- | -- | -- | |

| 250ºF (121ºC) |

1100 psi | 830 psi | 660 psi | -- | -- | -- |

| (75 bar) | (57 bar) | (45 bar) | -- | -- | -- |

3, 4 or 6 inch high pressure clamp not available.

*6" valves available in W61 Shutoff and W65 Divert only. For other valve types contact SPX FLOW.

Seat Options:

- Tef-Flow™ P

- Metal

Port Options:

W = Weld

S = S-Line

I = I-Line (female - 15I)

14I = I-Line (male - 14I)

B = Bevel Seat (male threaded end)

F = Flange

Q = Q-Line

D = DIN 11851 405 Thread

A = Aseptic I-Line (15NI)

For mixed connection types, specify in order of port #.

Adapter Options:

Standard W60 Adapter: The ‘standard’ adaptor is used on all models of short and long stroke W60 Series valves. Machined from SS 316L bar with a thick cross-section, the adaptor adds strength to the valve body and provides alignment for the stem. The outer perimeter seals to the valve body with an o-ring that is located forward to the product zone to minimize crevices. The product stem passes through the adaptor and is sealed to the adaptor with an o-ring. A Teflon® bearing guides the stem and takes up the mechanical loading imparted by hydraulic forces. This increases the service life of the stem seal. Adaptors are made in 1"-6" (25mm -152mm) sizes.

W60 High Pressure Adapter: The pressure limitation of the W60 adaptor is the sealing capability of the dynamic o-ring on the product stem. This variation of the W60 adaptor uses a backing ring added on the atmospheric side to support the stem o-ring. This significantly boosts the pressure rating on the stem o-ring. The product stem passes through the adaptor and is sealed to the adaptor with an o-ring and is guided by a Teflon® bearing.

W80 Adapter: This adaptor is used to convert a ‘standard’ W60 series valve to a W80. The outer perimeter seals to the valve body with an o-ring that is located forward to the product zone to minimize crevices. The product stem passes through the adaptor and is sealed in the upper part and the lower part of the adaptor with o-rings. The space between the o-rings is flushed with a suitable liquid or steam. The Teflon® bearing is located in the flushed chamber. Adaptors are made in 1"-6" (25mm - 152mm) sizes. For vacuum-rated, extended shelf-life (ESL) applications, the W80A adaptor adds steam trace to the adapter-to-valve body connection.

Wiping Stem Seal Adapter: For high-risk and hard to clean product applications, the wiping stem seal fills the gap between the product zone and the traditional o-ring stem seal. The adaptor is a two-piece design to allow easy inspection or replacement of the wiping stem seal. The outer perimeter seals to the valve body with an o-ring that is located forward to the product zone to minimize crevices. A Teflon® bearing is used to guide and support the valve stem.