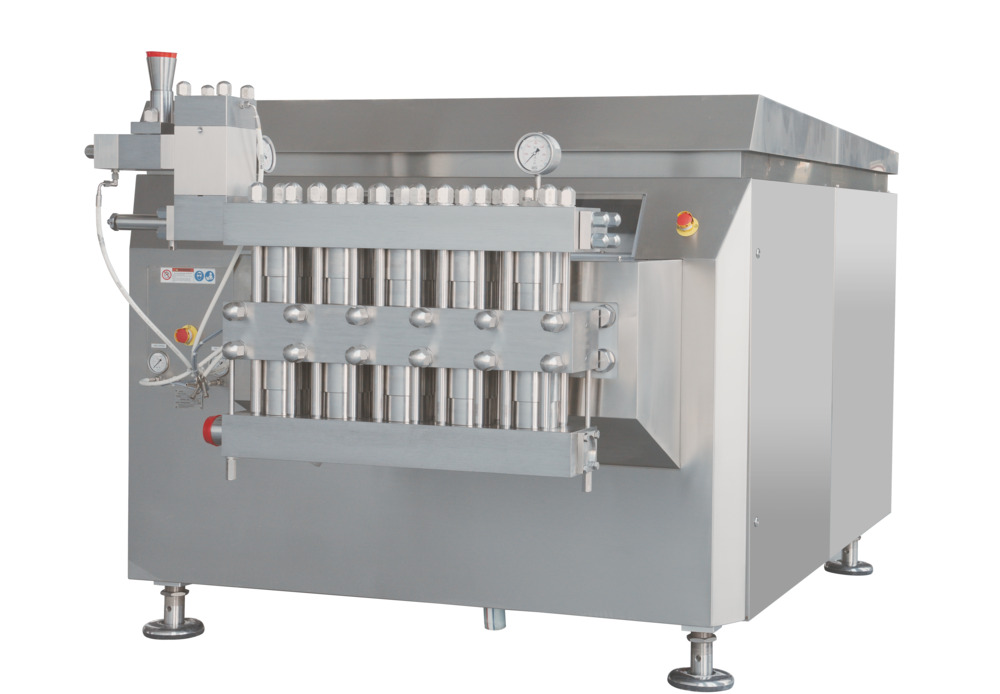

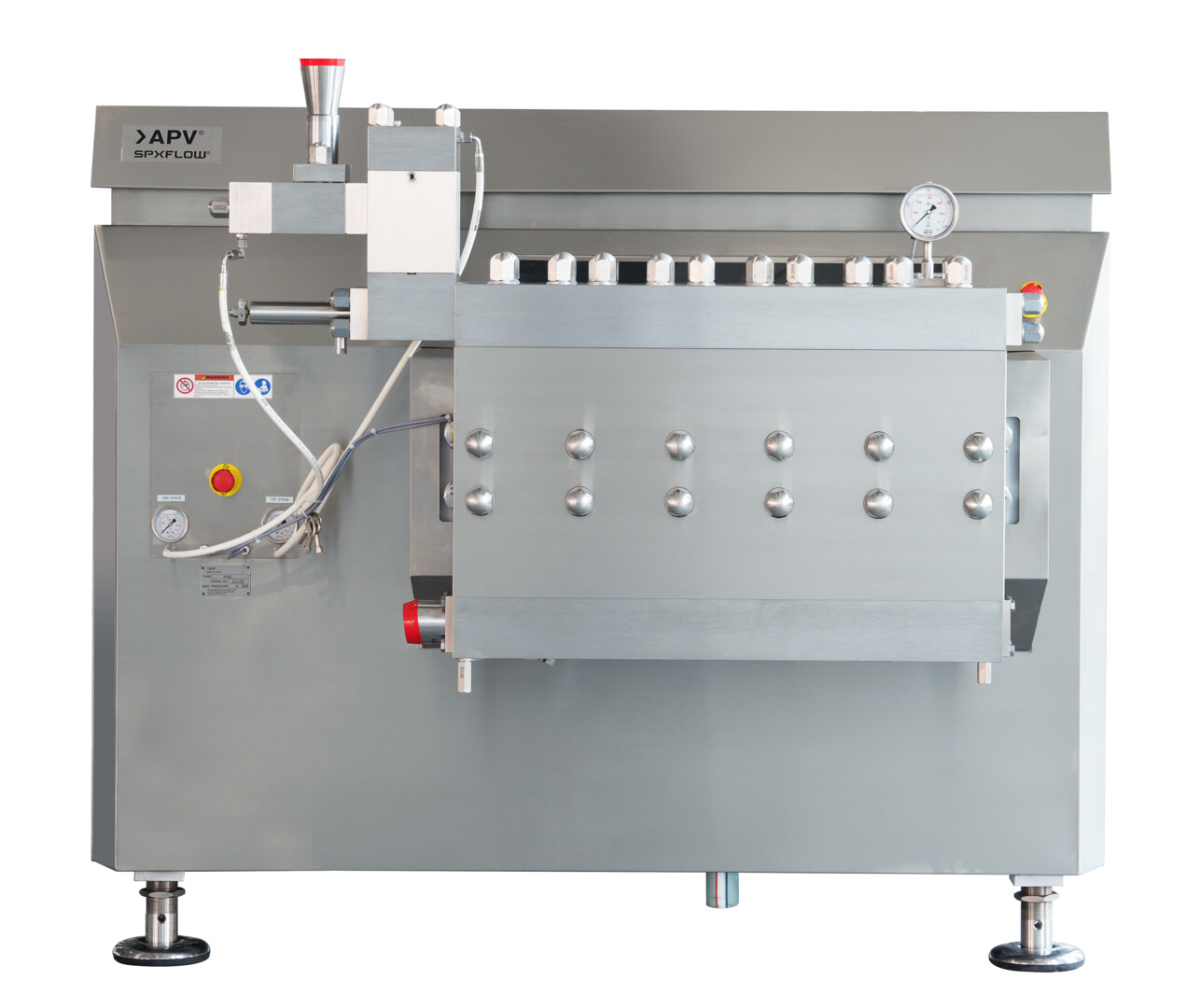

APV Rannie® 160Q / Gaulin® 160Q - High Pressure Homogenizers

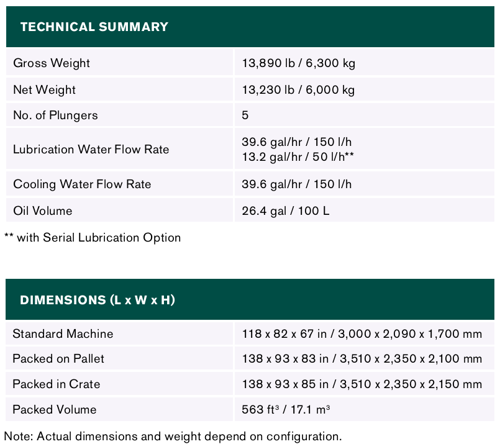

The Rannie 160Q and Gaulin 160Q are high-performance, high-pressure 5 plunger homogenizers engineered for superior particle size reduction and emulsion stability. Designed for a wide range of industrial and sanitary applications, these homogenizers deliver consistent results with maximum efficiency and reliability.