APV Rannie® 160T / Gaulin® 160T - High Pressure Homogenizers

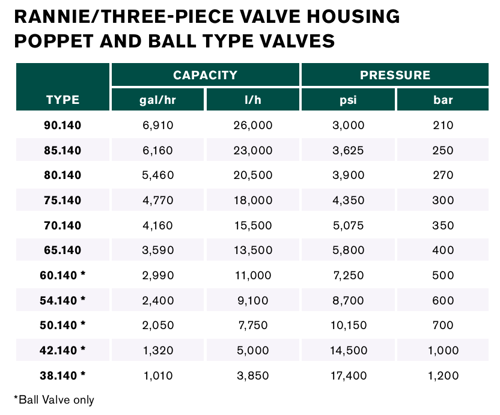

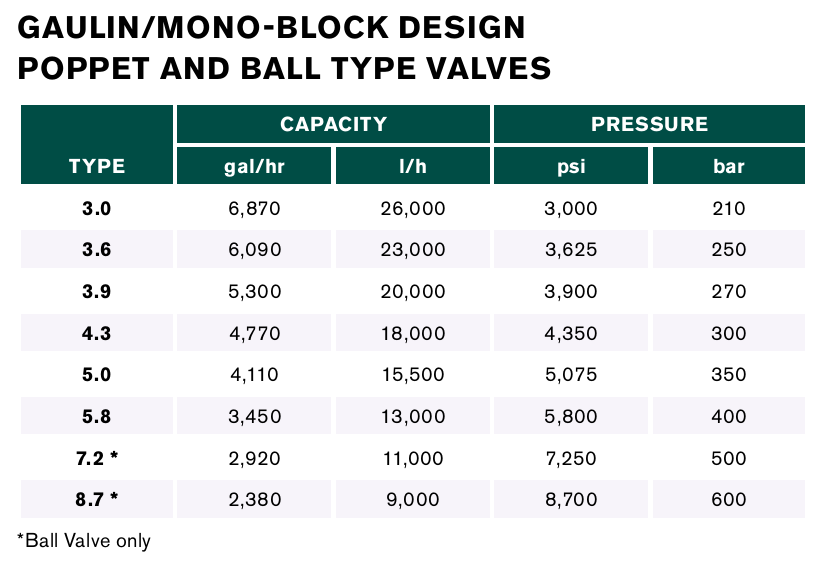

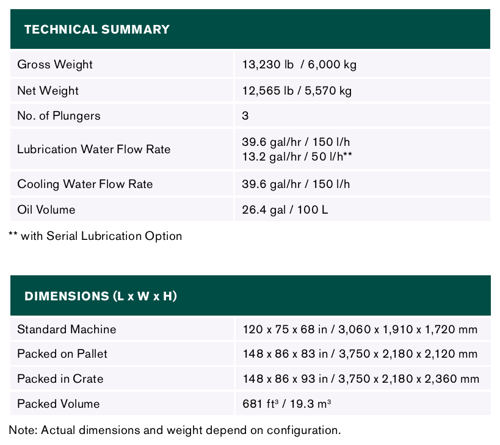

The APV Rannie® 160T and Gaulin® 160T high-pressure homogenizers are engineered for superior particle size reduction and enhanced emulsion stability. Featuring a robust 3-plunger design, these high-performance homogenizers deliver reliable, consistent results across a wide range of industrial and sanitary applications—maximizing efficiency, uptime, and process control.