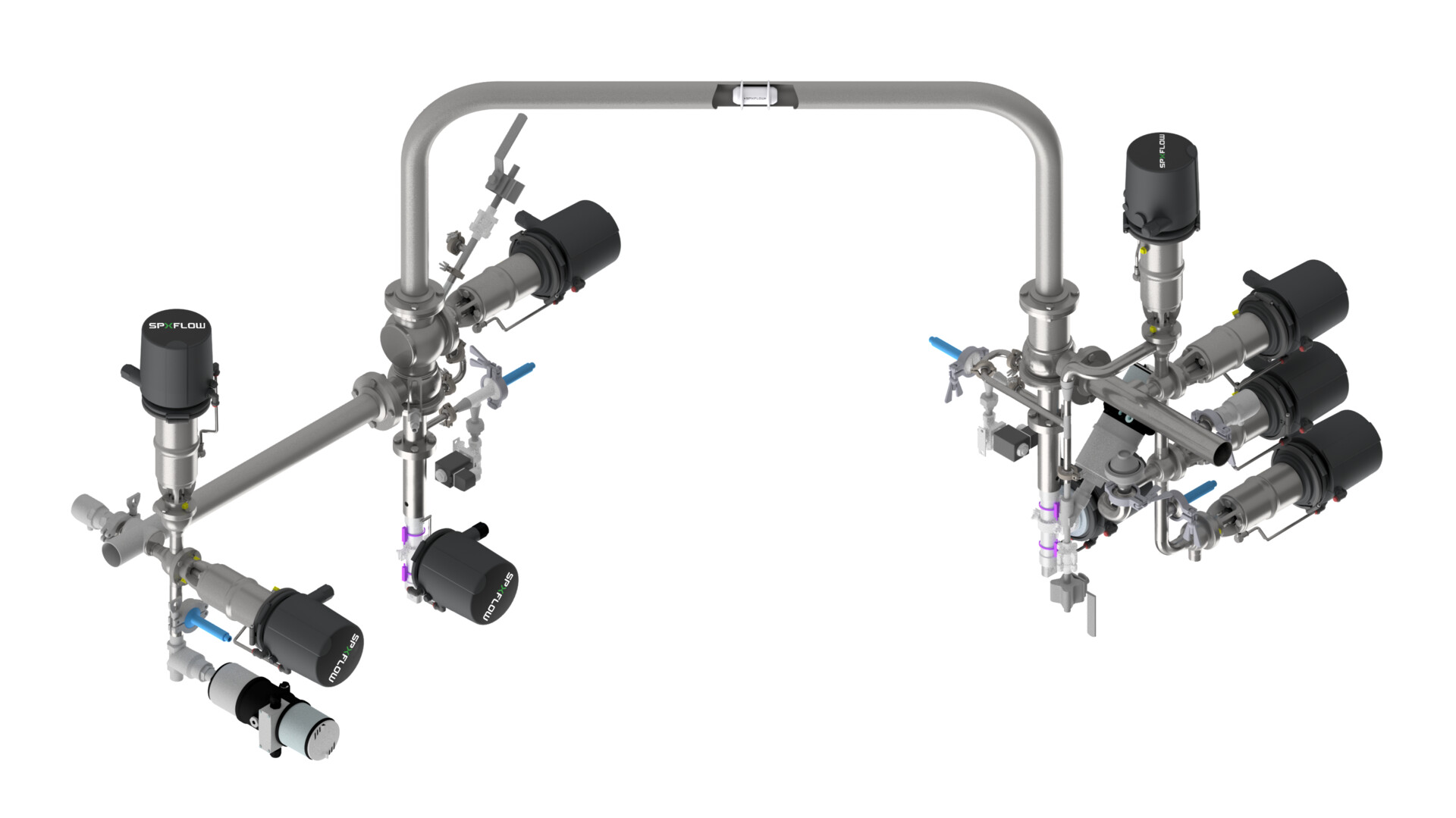

Aseptic Pigging Systems

The award-winning APV® Aseptic Pigging System (ARRS) efficiently recovers product from process pipes requiring stringent hygiene and sterile conditions, ensuring high food integrity. The system provides a sustainable solution that increases productivity, reduces waste, and enhances product yields. It is widely used in manufacturing lines for extended-shelf-life (ESL) products and long shelf-life products, such as yogurts and desserts, as well as plant-based alternatives, ice cream and some types of personal care products.