Next Generation Mixproof Valve Technology: SPX FLOW D4 Series

Advanced Fluid Separation for Process Industries

The next generation of mixproof valve technology is the result of continued development from both APV and Waukesha Cherry-Burrell process technologies. Used for the reliable separation of dissimilar fluids, the D4 Series helps fulfill todays customer demands for production flexibility, increased productivity, rapid return on investment (ROI), and improved product quality across the Food & Beverage, Dairy, Personal Care and Brewing process industries.

Value and Efficiency

High Value with Low Lifecycle Costs

- Tiered model range helps to increase ROI and align with customer budgets

- All In standard features provide exceptional value

- Reduced inventory costs with same seal kit used on multiple size ranges: DN40-DN65 (1.5-3.0) and DN80-DN100 (4.0)

- Reduced CIP losses improve cost savings

- Low air consumption and air supply requirements

- Long housing ports ease manifold building

- Integrated shaft seal flush reduces need for external piping

- Replacement insert available to easily upgrade existing installations

Reliable Performance

Optimized Operation and Control

- Fully balanced design helps to prevent hydraulic blocking, withstand pressure spikes, and enables flexible flow direction without slamming

- Light overall weight helps support handling without lifting tools

- Slim stainless actuator is fully enclosed to prevent fluid ingress

- Range of control units and bus communication for automated operation

- No compressed air needed for removal and servicing

Cleanability and Hygienic Design

Advanced Sanitary Features

- Designed to the latest hygienic standards

- Standard cavity spray cleaning

- Extensive cleaning of product contact seals

Valve Feature Comparison

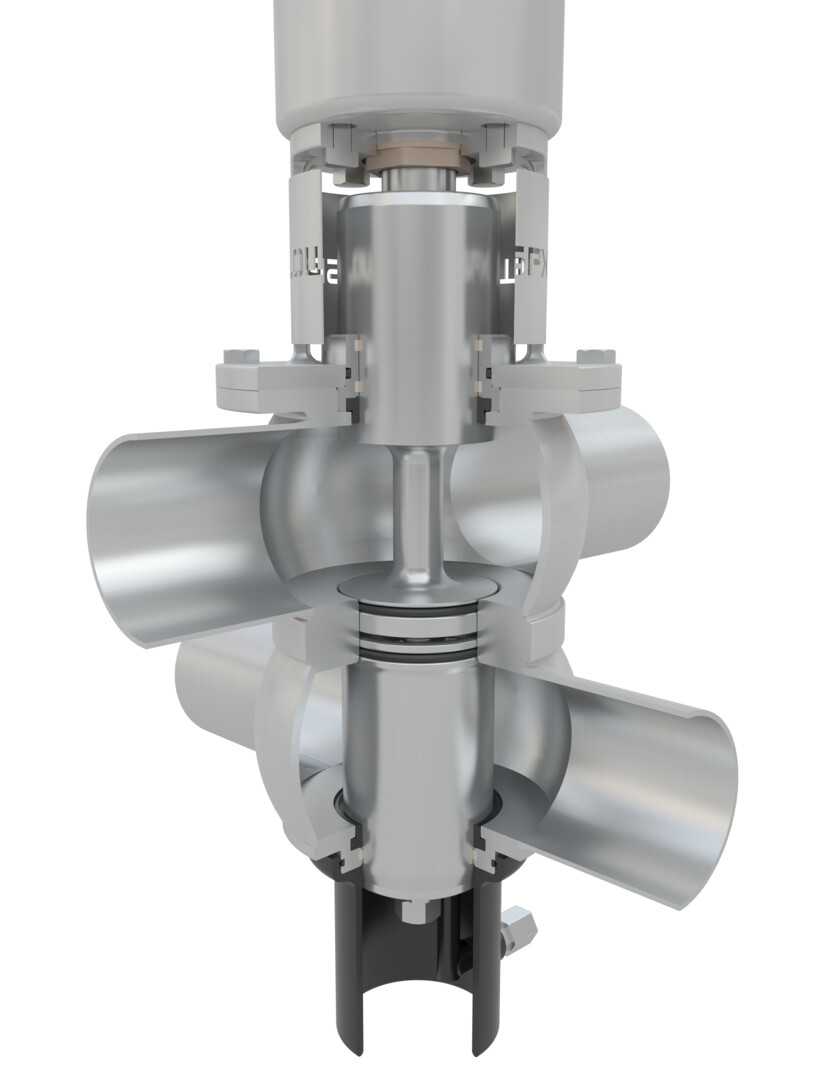

D4 Valve Key Features

- Radial seal design minimizes product loss and enhances cleanliness

- Choice of seat-lifting (SL) or non-seat-lifting (NSL) actuators

- Hazardous-rated options (ATEX Zone 1 or 2)

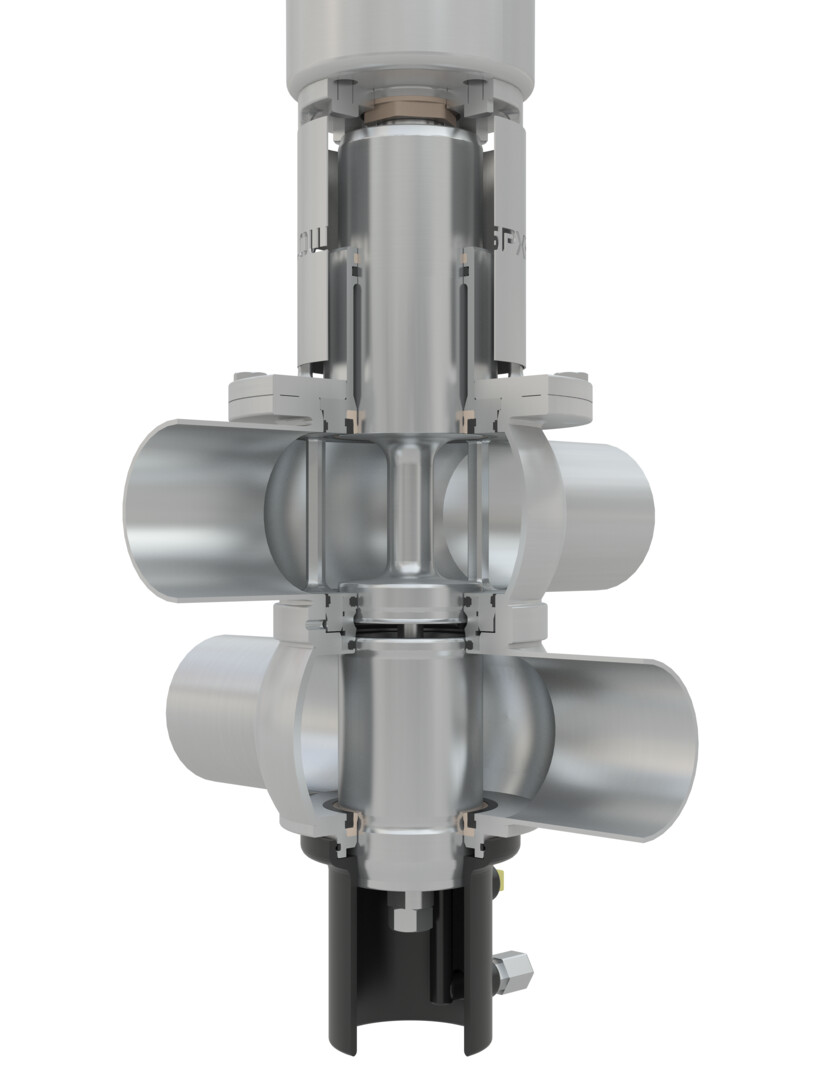

DA4 Valve Key Features

- Flushing for upper/lower shaft seals and balancer

- Metal orifices reduce CIP fluid consumption

- Insert upgrade compatible with DA3+ housing

Shared Features in D4 & DA4

- Open yoke enables leak detection and reduces heat transfer

- Bolted flange for secure insert connection

- Long ports for streamlined manifold assembly

- Two standardized seal kit sizes for all models

- Fully integrated position sensors

- No compressed air needed for servicing

- Balanced shaft design eliminates water hammer and supports dual flow direction

- Reduced chemical and cleaning fluid losses

- Large separation cavity drain port prevents cross-contamination

- Flush cavity spray connection for enhanced cleaning

- Lightweight valve body for easier handling

Actuator Warranty & Reliability

The actuator supplied with this valve is covered by a 5-year actuator warranty, or up to 1 million actuations, whichever comes first. Built with fully welded, sealed, maintenance-free construction, it eliminates internal servicing and reduces wear components to deliver long-term durability in demanding hygienic processing environments.

Key benefits include:

- Maintenance-free operation with no internal servicing

- Fewer spare parts and improved total cost of ownership

- uptime and production continuity

Key Applications

Food and Beverage

- Soups & Sauces

- Flavorings & Ingredients

- Dressings, Vinegars

- Soft/Fruit & Vegetable Drinks

- Brewery, Wort, Wine, Distillery

- Pet Food

- Fats & Oils, Animal Oils

- Liquid Sugar

- Cereals

Personal Care and Pharmaceutical

- Fluid Medicines

- Extracts

- Face Creams & Lotions

- Perfumes

- Soaps

- High Purity Water

- Nutritional Supplements

- Hair Styling Gels & Liquids

- Dyes & Alcohols

Chemical

- Solvents, Paints

- Adhesives

- Coatings

- Oils & Lubricants

- Detergents

- Emulsions

- Fuels

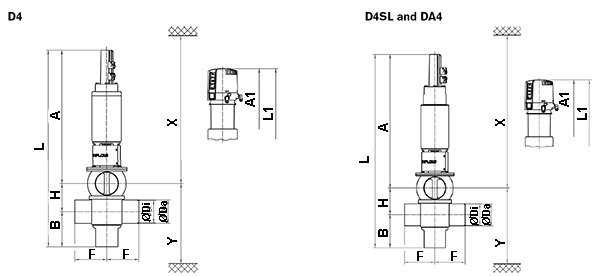

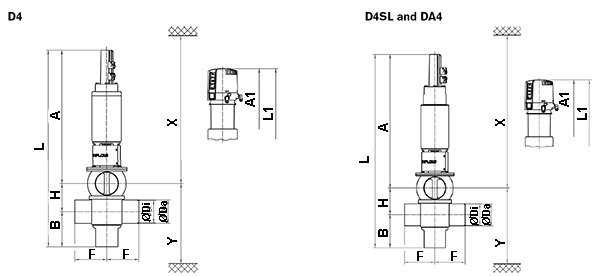

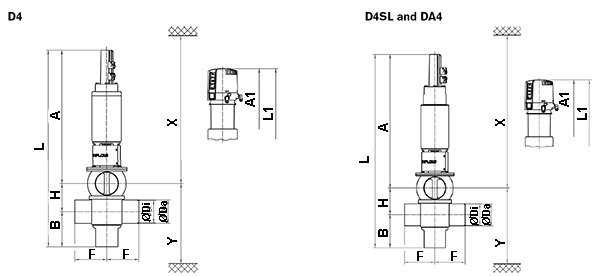

D4

| Dimensions mm | A | A1 | B | øDa | øDi | F | H | L | L1 | X* | Y* |

| DN | |||||||||||

| 40 | 483 | 566 | 120 | 41 | 38 | 125 | 63 | 666 | 749 | 820 | 200 |

| 50 | 487 | 570 | 126 | 53 | 50 | 125 | 75 | 688 | 771 | 830 | 218 |

| 65 | 495 | 578 | 134 | 70 | 66 | 125 | 91 | 720 | 803 | 840 | 242 |

| 80 | 583 | 666 | 146 | 85 | 81 | 142.5 | 106 | 835 | 918 | 930 | 274 |

| 100 | 593 | 676 | 156 | 104 | 100 | 142.5 | 125 | 874 | 957 | 940 | 303 |

| 125 | 677 | 760 | 179 | 129 | 125 | 150 | 150 | 1006 | 1089 | 1030 | 350 |

| 150 | 725 | 793 | 194 | 154 | 150 | 150 | 175 | 1094 | 1162 | 1075 | 390 |

| INCH | |||||||||||

| 1.5 | 485 | 568 | 119 | 38.1 | 34.8 | 125 | 63 | 667 | 750 | 820 | 197 |

| 2.0 | 488 | 571 | 125 | 50.8 | 47.6 | 125 | 75 | 688 | 771 | 830 | 216 |

| 2.5 | 492 | 575 | 131 | 63.5 | 60.3 | 125 | 85.3 | 708.3 | 791.3 | 840 | 233 |

| 3.0 | 498 | 581 | 137 | 76.1 | 72.9 | 125 | 97.9 | 732.9 | 815.9 | 850 | 251 |

| 4.0 | 594 | 677 | 155 | 101.6 | 97.6 | 142.5 | 125 | 874 | 957 | 840 | 301 |

| 6.0 | 726 | 795 | 193 | 152.4 | 147.3 | 149.8 | 175 | 1095 | 1161 | 1080 | 391 |

*Minimum installation and valve insert removal dimensions

D4 SL

| Dimensions mm | A | A1 | B | øDa | øDi | F | H | L | L1 | X* | Y* |

| DN | |||||||||||

| 40 | 524 | 607 | 120 | 41 | 38 | 125 | 63 | 707 | 790 | 870 | 200 |

| 50 | 528 | 611 | 126 | 53 | 50 | 125 | 75 | 729 | 812 | 880 | 218 |

| 65 | 536 | 619 | 134 | 70 | 66 | 125 | 91 | 761 | 844 | 890 | 242 |

| 80 | 618 | 701 | 146 | 85 | 81 | 142.5 | 106 | 870 | 953 | 980 | 274 |

| 100 | 628 | 711 | 156 | 104 | 100 | 142.5 | 125 | 909 | 992 | 990 | 303 |

| 125 | 677 | 760 | 179 | 129 | 125 | 150 | 150 | 1006 | 1089 | 1030 | 350 |

| 150 | 725 | 793 | 194 | 154 | 150 | 150 | 175 | 1094 | 1162 | 1075 | 390 |

| INCH | |||||||||||

| 1.5 | 526 | 609 | 119 | 38.1 | 34.8 | 125 | 63 | 708 | 791 | 870 | 197 |

| 2.0 | 529 | 612 | 125 | 50.8 | 47.6 | 125 | 75 | 729 | 812 | 880 | 216 |

| 2.5 | 534 | 617 | 131 | 63.5 | 60.3 | 125 | 85.3 | 750.3 | 833.3 | 900 | 233 |

| 3.0 | 540 | 623 | 137 | 76.1 | 72.9 | 125 | 97.9 | 774.9 | 857.9 | 900 | 251 |

| 4.0 | 629 | 712 | 155 | 101.6 | 97.6 | 142.5 | 125 | 909 | 992 | 990 | 301 |

| 6.0 | 726 | 795 | 193 | 152.4 | 147.3 | 150 | 175 | 1095 | 1161 | 1080 | 391 |

*Minimum installation and valve insert removal dimensions

DA4

| Dimensions mm | A | A1 | B | øDi | øDa | F | H | L | L1 | X* | Y* |

| DN | |||||||||||

| 40 | 589 | 672 | 120 | 38 | 41 | 125 | 63 | 772 | 855 | 930 | 200 |

| 50 | 593 | 676 | 126 | 50 | 53 | 125 | 75 | 794 | 877 | 940 | 218 |

| 65 | 601 | 684 | 134 | 66 | 70 | 125 | 91 | 826 | 909 | 950 | 242 |

| 80 | 678 | 761 | 146 | 81 | 85 | 142.5 | 106 | 930 | 1013 | 1030 | 274 |

| 100 | 688 | 771 | 156 | 100 | 104 | 142.5 | 125 | 969 | 1052 | 1040 | 303 |

| INCH | |||||||||||

| 1.5 | 588 | 671 | 119 | 34.8 | 38.1 | 125 | 63 | 770 | 853 | 930 | 197 |

| 2.0 | 594 | 677 | 125 | 47.6 | 50.8 | 125 | 75 | 794 | 877 | 940 | 216 |

| 2.5 | 598 | 681 | 131 | 60.3 | 63.5 | 125 | 85.3 | 814.3 | 897.3 | 950 | 233 |

| 3.0 | 604 | 687 | 137 | 72.9 | 76.1 | 125 | 97.9 | 838.9 | 921.9 | 960 | 251 |

| 4.0 | 689 | 772 | 155 | 97.6 | 101.6 | 142.5 | 125 | 969 | 1052 | 1050 | 301 |

*Minimum installation and valve insert removal dimensions

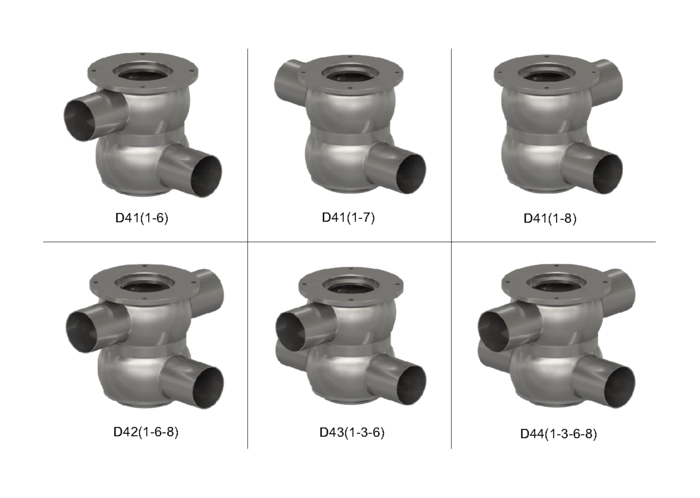

Housing Combinations

Shut-off Valves

Mixproof shut-off valves are used to keep incompatible products from mixing at pipe junctions, or to simply shut flow from an upper to lower line within a valve matrix.

Divert Valves

Mixproof divert valves are used for distributing liquid from one pipeline into two others (or vice versa)

Control Units

CU4 & CU4plus Series - Benefits

- Automated control and position monitoring for reliable processing

- Reduces compressed air and electrical connections

- Helps reduce external solenoid valve cabinets

- Accelerates valve response time

- Innovative seat lift detection is fully integrated without need for external sensor wiring to provide additional position monitoring

- Reliability and long service life - robust clamp connection, reinforced stainless steel air coupling threads to avoid air leakages, and water tight seals

- Ease of operation - contains manual override solenoids and adjustment screw to throttle air flow to actuator to ensure optimal opening and closing

- Clarity - clear and bright indication of valve position - 5 diodes in LED panel and convenient location

- Standardization - same control top used on various SPX FLOW valve lines, offers common look and controls interface

- Robust design suited for NEMA6/IP67/IP69k* wash-down rating

- ATEX / IECEx rated environments

|

CONNECTOR OPTIONS S/O Cord Grip for hard wire (std) M12 4-pin connector (optional) |

POSITION INDICATION CU4: 2 internal feedback sensors for valve open/valve closed position detection |

|

INTERFACE OPTIONS 24V DC Direct Connect AS-i Field Bus Card IO-Link |

SOLENOID VALVES 24V DC Select 1 (non seat lift) or 3 Solenoids (seat lift) |

*IP69K compliance achieved by modification of the exhaust

8681 Control Unit - Benefits

- Contact free position sensor including (3) programmable feedback signals

- Positions easily taught via intuitive push buttons or Autotune feature to ensure quick & easy set-up

- Ultra-bright 360° visual LED position indication with adjustable red, yellow, & green color assignments provide clarity from all points of view and avoid confusion

- Manual override and air throttle adjustable solenoids to assist start-up, maintenance, and troubleshooting

- Up to IP69K washdown rating available (IP65/67 as standard) for high washdown environments

- Built-in microcontroller tracks cycles and alerts operator when preventive maintenance is required

- Simple and robust stainless steel adapter & chemically resistant polycarbonate head

- Supplied by industry leading Burkert Fluid Controls

|

CONNECTOR OPTIONS Quick Disconnect Pin Connector |

POSITION INDICATION (3) programmable position sensors in control top |

|

INTERFACE OPTIONS AS-i Field Bus Card DeviceNet™ Field Bus Network Card |

SOLENOID VALVES 24V DC Manual override and air throttle adjustment Up to (3) available in control top |

- Max. line pressure 10 bar

- Max. operating temperature 135 °C

- Short-term load 140 °C