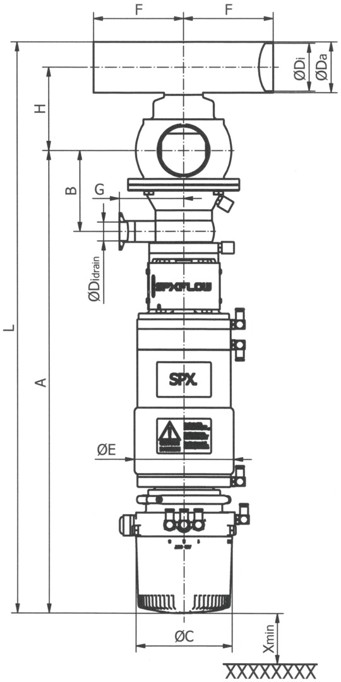

DP4 – Piggable Valve

Piggable valves enable you to recover costly products out of product lines. Once the pig is forced through the line, the remaining product film on the inside of the product line can then be removed with much less CIP fluid which lowers the amount of wastewater, cleaning fluids and cleaning time. They are particularly well suited in processing viscous fluids.