The DW Positive Displacement Pump Series delivers high volumetric efficiency with minimized internal clearances for cost savings. It ensures ultra-hygienic operation, handles harsh CIP/SIP cycles and provides pulse-free performance for consistent flow. With gentle product handling, low NPSH requirements, easy maintenance and low noise levels.

The APV DW Pump Series will be superseded by the next-generation APV DW+ pump, effective April 1, 2025. This change applies to all DW1-5 models, while the DW6 model will remain unchanged. For more information about our next-generation pumps, visit DW+ Series – Piston & Bi-Lobe Rotor Pumps

Key Features

The DW Positive Displacement Pump Series has 26 DW models are hygienic, it is 3A approved and designed to EHEDG standards. It covers all requirements from 3 litres /100 revs to 1016/100 revs. Maximum pressure up to 435 psi (30 bar.) All product contact parts are AISI 316L stainless steel and elastomers comply with FDA-requirements.

Benefits

- High volumetric efficiency- The DW model range is designed according to the principle: 'More pump for your money'. Internal clearances have been minimized making the pump so efficient that in medium viscosity applications a smaller pump size than usual will do the job. This reduces both initial investment and running costs.

- Ultra-hygienic, accommodates harsh CIP-cycles - All DW models are CIP/SIP cleanable. The pumps are designed to withstand rapid temperature changes and can therefore accommodate very harsh CIP-cycles.

- Pulse-free performance - When pumping highly viscous products, the DW circumferential piston pumps run completely pulse-free. This ensures a constant process flow, as required for instance in connection with filling machines, safeguards valves, and other equipment that is liable to damage through pressure surges.

- Low NPSH-requirement - The highly improved suction capabilities of the DW pump considerably reduce the NPSH-requirement (Net Positive Suction Head required). In combination with the absence of pressure pulsations, this makes the DW pumps ideal for many applications, such as ultra-filtration.

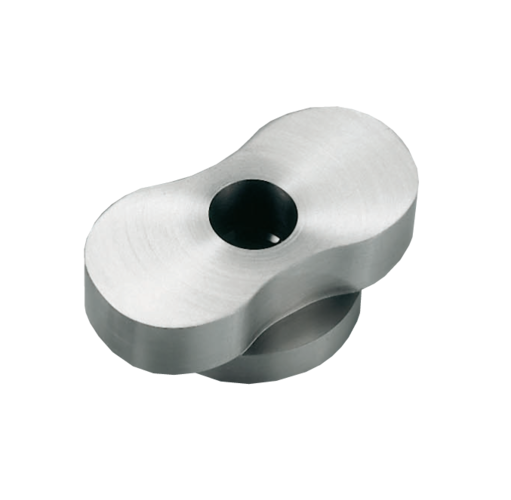

- Gentle product handling - The rotor designs ensure maximum product integrity and minimize risk of potential damage to sensitive products. The circumferential piston rotors, as well as the new twin lobe rotors are suitable both for high and low viscosities and will also handle cheese curds and whey, soft fruit and meat which until now required fitting of special rotors.

- Easy Maintenance - The easy-to-access front loaded mechanical seals reduce maintenance time considerably. All shaft seal O-rings are identical and access to the shaft seal is achieved by simply removing the front cover and the rotors. Likewise, timing of rotors is an uncomplicated procedure.

- Low noise levels - Unique rotor design practically eliminates hydraulic noise, and the helical gears minimize gearbox noise.

Key Applications

Food & Beverages

- Fruit Preserves

- Soups and Sauces

- Baby Food

- Chocolate

- Fruit Juice

- Cider and Wine

- Yeast

- Liquid Sugar and Glucose

Dairy

- Cream

- Butter

- Cheese Curd & Whey

- Yogurt

- Ice cream

Pharmaceutical and Toiletries

- Antibiotics

- Toothpaste

- Cough Medicine

- Shampoo

Chemicals

- Paint

- Oil Additives

- Resins

- Photographic Film Coatings

The DW pump is designed for ultra-hygienic applications. The range consists of 26 models with capacities ranging from 0.8 gal/100 revs to 268 gal/100 revs (3 liters/100 revs to 1,016 liters /100 revs) and pressures up to 435 psi (30 bar). All product-contact parts are made from AISI 316L stainless steel and all elastomers comply with FDA-requirements.

There are two rotor types (piston and bi-lobe) available. The piston rotors can be easily changed to bi-lobe rotors without changing the rotor case. The porting on the pump can also be changed from horizontal to vertical (and vice versa) without any modification to the pump or use of a special gear case assembly.

|

MODEL |

ROTOR TYPE |

MAXIMUM DISPLACEMENT |

MAXIMUM PRESSURE |

|---|---|---|---|

| DW1/003/7.5 | Piston | 0.8 (3) | 109 (7.5) |

| DW1/004/15 | Bi-lobe | 1.1 (4) | 218 (15) |

| DW1/007/7 | Bi-lobe | 1.8 (7) | 102 (7) |

| DW2/006/10 | Piston | 1.6 (6) | 145 (10) |

| DW2/007/20 | Bi-lobe | 1.8 (7) | 200 (20) |

| DW2/013/10 | Bi-lobe | 3.4 (13) | 145 (10) |

| DW3/014/10 | Piston | 3.7 (14) | 145 (10) |

| DW3/017/20 | Bi-lobe | 4.5 (17) | 290 (20) |

| DW3/030/10 | Bi-lobe | 7.9 (30) | 145 (10) |

| DW3/050/5 | Bi-lobe | 13.2 (50) | 73 (5) |

| DW4/033/10 | Piston | 8.7 (33) | 145 (10) |

| DW4/039/20 | Bi-lobe | 10.3 (39) | 290 (20) |

| DW4/073/10 | Bi-lobe | 19.3 (73) | 145 (10) |

| DW4/125/5 | Bi-lobe | 33.0 (125) | 73 (5) |

| DW5/080/12.5 | Piston | 21.1 (80) | 181 (12.5) |

| DW5/093/25 | Bi-lobe | 24.6 (93) | 363 (25) |

| DW5/142/15 | Bi-lobe | 37.5 (142) | 218 (15) |

| DW5/256/7 | Bi-lobe | 67.6 (256) | 102 (7) |

| DW6/172/12.5 | Piston | 45.4 (172) | 218 (15) |

| DW6/198/30 | Bi-lobe | 52.3 (198) | 435 (30) |

| DW6/308/15 | Bi-lobe | 81.4 (308) | 218 (15) |

| DW6/519/07 | Bi-lobe | 137.1 (519) | 102 (7) |

Model DW1/003/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 8.54 | 1.57 | 1.5 | 4.29 | 4.76 | 0.47 | 5.75 | 5.9 | 6.53 | 4.8 | 7.6 | 3.7 | 3.27 | DN15 | 218 | 86 | 18 | 8 |

| MM | 217 | 40 | 38 | 109 | 121 | 12 | 146 | 150 | 166 | 122 | 193 | 94 | 83 | 218 | 86 | 18 | 8 | 17 |

Weight: 37.48 lbs (17 Kg)

Oil Capacity: 0.21 GAL (0.8 L)

Model DW1/004/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 8.54 | 1.57 | 1.5 | 4.29 | 4.76 | 0.47 | 5.75 | 5.9 | 6.53 | 4.8 | 7.6 | 3.7 | 3.27 | DN15 | 8.58 | 3.38 | 0.71 | 0.31 |

| MM | 217 | 40 | 38 | 109 | 121 | 12 | 146 | 150 | 166 | 122 | 193 | 94 | 83 | 218 | 86 | 18 | 8 |

Weight: 37.48 lbs (17 Kg)

Oil Capacity: 0.21 GAL (0.8 L)

Model DW1/007/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 8.74 | 1.57 | 1.5 | 4.29 | 4.76 | 0.47 | 5.75 | 5.9 | 6.53 | 4.8 | 7.6 | 3.7 | 3.27 | 1 | 8.58 | 3.38 | 0.71 | 0.31 |

| MM | 222 | 40 | 38 | 109 | 121 | 12 | 146 | 150 | 166 | 122 | 193 | 94 | 83 | 25 | 218 | 86 | 18 | 8 |

Weight: 39.68 lbs (18 Kg)

Oil Capacity: 0.21 GAL (0.8 L)

Model DW2/006/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 9.76 | 1.97 | 1.42 | 4.72 | 5.59 | 0.67 | 6.93 | 7.01 | 7.64 | 5.71 | 8.98 | 4.41 | 3.82 | 1 | 9.92 | 3.86 | 0.87 | 0.47 |

| MM | 248 | 50 | 36 | 120 | 142 | 17 | 176 | 178 | 194 | 145 | 228 | 112 | 97 | 25 | 252 | 98 | 22 | 12 |

Weight: 55.11 lbs (25 Kg)

Oil Capacity: 0.34 GAL (1.3 L)

Model DW2/007/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 9.76 | 1.97 | 1.42 | 4.72 | 5.59 | 0.67 | 6.93 | 7.01 | 7.64 | 5.71 | 8.98 | 4.41 | 3.82 | 1 | 9.92 | 3.86 | 0.87 | 0.47 |

| MM | 248 | 50 | 36 | 120 | 142 | 17 | 176 | 178 | 194 | 145 | 228 | 112 | 97 | 25 | 252 | 98 | 22 | 12 |

Weight: 55.11 lbs (25 Kg)

Oil Capacity: 0.34 GAL (1.3 L)

Model DW2/013/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 9.92 | 1.97 | 1.42 | 4.72 | 5.59 | 0.67 | 6.93 | 7.01 | 7.64 | 5.71 | 8.98 | 4.41 | 3.82 | 1.5 | 9.92 | 3.86 | 0.87 | 0.47 |

| MM | 252 | 50 | 36 | 120 | 142 | 17 | 176 | 178 | 194 | 145 | 228 | 112 | 97 | 38 | 252 | 98 | 22 | 12 |

Weight: 59.52 lbs (27 Kg)

Oil Capacity: 0.34 GAL (1.3 L)

Model DW3/014/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 10.67 | 2.36 | 1.57 | 4.84 | 6.3 | 0.79 | 7.87 | 7.72 | 8.35 | 6.22 | 9.92 | 4.72 | 4.17 | 1.5 | 10.75 | 4.41 | 0.98 | 0.51 |

| MM | 271 | 60 | 40 | 123 | 160 | 20 | 200 | 196 | 212 | 158 | 252 | 120 | 106 | 38 | 273 | 112 | 25 | 13 |

Weight: 74.96 lbs (34 Kg)

Oil Capacity: 0.37 GAL (1.4 L)

Model DW3/017/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 10.67 | 2.36 | 1.57 | 4.84 | 6.3 | 0.79 | 7.87 | 7.72 | 8.35 | 6.22 | 9.92 | 4.72 | 4.17 | 1.5 | 10.75 | 4.41 | 0.98 | 0.51 |

| MM | 271 | 60 | 40 | 123 | 160 | 20 | 200 | 196 | 212 | 158 | 252 | 120 | 106 | 38 | 273 | 112 | 25 | 13 |

Weight: 74.96 lbs (34 Kg)

Oil Capacity: 0.37 GAL (1.4 L)

Model DW3/030/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 11.02 | 2.36 | 1.57 | 4.84 | 6.3 | 0.79 | 7.87 | 7.72 | 8.35 | 6.22 | 9.92 | 4.72 | 4.17 | 2 | 10.75 | 4.41 | 0.98 | 0.51 |

| MM | 280 | 60 | 40 | 123 | 160 | 20 | 200 | 196 | 212 | 158 | 252 | 120 | 106 | 51 | 273 | 112 | 25 | 13 |

Weight: 88.18 lbs (40 Kg)

Oil Capacity: 0.37 GAL (1.4 L)

Model DW3/050/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 11.97 | 2.36 | 1.57 | 4.84 | 6.3 | 0.79 | 7.87 | 7.72 | 8.35 | 6.22 | 9.92 | 4.72 | 4.17 | 2 | 10.75 | 4.41 | 0.98 | 0.51 |

| MM | 304 | 60 | 40 | 123 | 160 | 20 | 200 | 196 | 212 | 158 | 252 | 120 | 106 | 51 | 273 | 112 | 25 | 13 |

Weight: 99.21 lbs (45 Kg)

Oil Capacity: 0.37 GAL (1.4 L)

Model DW4/033/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 13.86 | 3.15 | 1.77 | 6.38 | 8.07 | 0.79 | 9.64 | 9.37 | 10.24 | 7.48 | 11.81 | 5.59 | 5.12 | 2 | 12.91 | 5.12 | 1.38 | 0.55 |

| MM | 352 | 80 | 45 | 162 | 205 | 20 | 245 | 238 | 260 | 190 | 300 | 142 | 130 | 51 | 328 | 130 | 35 | 14 |

Weight: 141.09 lbs (64 Kg)

Oil Capacity: 0.79 GAL (3.0 L)

Model DW4/039/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 14.37 | 3.15 | 1.77 | 6.38 | 8.07 | 0.79 | 9.64 | 9.37 | 10.24 | 7.48 | 11.81 | 5.59 | 5.12 | 3 | 12.91 | 5.12 | 1.38 | 0.55 |

| MM | 365 | 80 | 45 | 162 | 205 | 20 | 245 | 238 | 238 | 260 | 190 | 300 | 142 | 130 | 76 | 328 | 130 | 35 |

Weight: 158.73 lbs (72 Kg)

Oil Capacity: 0.79 GAL (3.0 L)

Model DW4/073/-

Model DW4/125/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 15.71 | 3.15 | 1.77 | 6.38 | 8.07 | 0.79 | 9.64 | 9.37 | 10.24 | 7.48 | 11.81 | 5.59 | 5.12 | 3 | 12.91 | 5.12 | 1.38 | 0.55 |

| MM | 399 | 80 | 45 | 162 | 205 | 20 | 245 | 238 | 260 | 190 | 300 | 142 | 130 | 76 | 328 | 130 | 35 | 14 |

Weight: 187.39 lbs (85 Kg)

Oil Capacity: 0.79 GAL (3.0 L)

Model DW5/080/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 18.86 | 4.17 | 2.79 | 9.13 | 10.31 | 0.98 | 12.28 | 11.93 | 12.83 | 9.45 | 14.57 | 6.97 | 6.42 | 2.5 | 17.09 | 6.5 | 1.65 | 0.67 |

| MM | 479 | 106 | 71 | 232 | 262 | 25 | 312 | 303 | 326 | 240 | 370 | 177 | 163 | 63 | 434 | 165 | 42 | 17 |

Weight: 332.90 lbs (151 Kg)

Oil Capacity: 1.85 GAL (7.0 L)

Model DW5/093/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 18.86 | 4.17 | 2.79 | 9.13 | 10.31 | 0.98 | 12.28 | 11.93 | 12.83 | 9.45 | 14.57 | 6.97 | 6.42 | 2.5 | 17.09 | 6.5 | 1.65 | 0.67 |

| MM | 479 | 106 | 71 | 232 | 262 | 25 | 312 | 303 | 326 | 240 | 370 | 177 | 163 | 63 | 434 | 165 | 42 | 17 |

Weight: 332.90 lbs (151 Kg)

Oil Capacity: 1.85 GAL (7.0 L)

Model DW5/142/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 19.49 | 4.17 | 2.79 | 9.13 | 10.31 | 0.98 | 12.28 | 11.93 | 12.83 | 9.45 | 14.57 | 6.97 | 6.42 | 3 | 17.09 | 6.5 | 1.65 | 0.67 |

| MM | 495 | 106 | 71 | 232 | 262 | 25 | 312 | 303 | 326 | 240 | 370 | 177 | 163 | 76 | 434 | 165 | 42 | 17 |

Weight: 337.30 lbs (153 Kg)

Oil Capacity: 1.85 GAL (7.0 L)

Model DW5/256/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 20.47 | 4.17 | 2.79 | 9.13 | 10.31 | 0.98 | 12.28 | 11.93 | 12.83 | 9.45 | 14.57 | 6.97 | 6.42 | DN | 17.09 | 6.5 | 1.65 | 0.67 |

| MM | 520 | 106 | 71 | 232 | 262 | 25 | 312 | 303 | 326 | 240 | 370 | 177 | 163 | 125 | 434 | 165 | 42 | 17 |

Weight: 379.19 lbs (172 Kg)

Oil Capacity: 1.85 GAL (7.0 L)

Model DW6/172/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 27.24 | 3.86 | 3.54 | 13.82 | 16.53 | 1.57 | 19.68 | 14.8 | 19.33 | 11.53 | 21.3 | 8.19 | 9.64 | 3 | 20.79 | 8.58 | 1.97 | 0.94 |

| MM | 692 | 98 | 90 | 351 | 420 | 40 | 500 | 376 | 491 | 293 | 541 | 208 | 245 | 76 | 528 | 218 | 50 | 24 |

Weight: 815.71 lbs (370 Kg)

Oil Capacity: 6.60 GAL (25 L)

Model DW6/198/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 27.24 | 3.86 | 3.54 | 13.82 | 16.53 | 1.57 | 19.68 | 14.8 | 19.33 | 11.53 | 21.3 | 8.19 | 9.64 | 3 | 20.79 | 8.58 | 1.97 | 0.94 |

| MM | 692 | 98 | 90 | 351 | 420 | 40 | 500 | 376 | 491 | 293 | 541 | 208 | 245 | 76 | 528 | 218 | 50 | 24 |

Weight: 815.71 lbs (370 Kg)

Oil Capacity: 6.60 GAL (25 L)

Model DW6/308/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 27.8 | 3.86 | 3.54 | 13.82 | 16.53 | 1.57 | 19.68 | 14.8 | 19.33 | 11.53 | 21.3 | 8.19 | 9.64 | 4 | 20.79 | 8.58 | 1.97 | 0.94 |

| MM | 706 | 98 | 90 | 351 | 420 | 40 | 500 | 376 | 491 | 293 | 541 | 208 | 245 | 102 | 528 | 218 | 50 | 24 |

Weight: 859.80 lbs (390 Kg)

Oil Capacity: 6.60 GAL (25 L)

Model DW6/519/-

|

|

|

|

| B | C | D | E | F | G | H | J | K | L | M | N | P | Q | S | T | U | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 28.82 | 3.86 | 3.54 | 13.82 | 16.53 | 1.57 | 19.68 | 14.8 | 19.33 | 11.53 | 21.3 | 8.19 | 9.64 | DN | 20.79 | 8.46 | 1.97 | 0.94 |

| MM | 732 | 98 | 90 | 351 | 420 | 40 | 500 | 376 | 491 | 293 | 541 | 208 | 245 | 150 | 528 | 215 | 50 | 24 |

Weight: 1014.12 lbs (460 Kg)

Oil Capacity: 6.60 GAL (25 L)