DW+ Series – Piston & Bi-Lobe Rotor Pumps

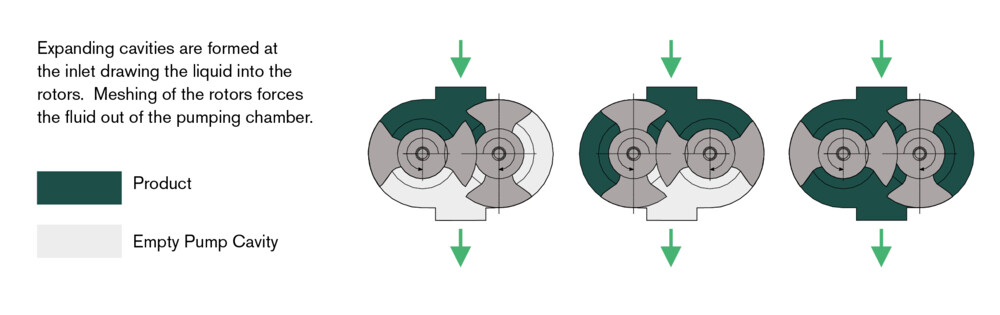

The DW+ Series is a versatile, positive displacement pump ideal for high-viscosity and shear-sensitive fluids. Its gentle, pulsation free, low shear design, ensures gentle consistent flow and easy maintenance. Perfect for dairy, beverage, food, pharmaceuticals, personal care, chemical and industrial markets, it meets stringent sanitary standards while boosting operational efficiency.