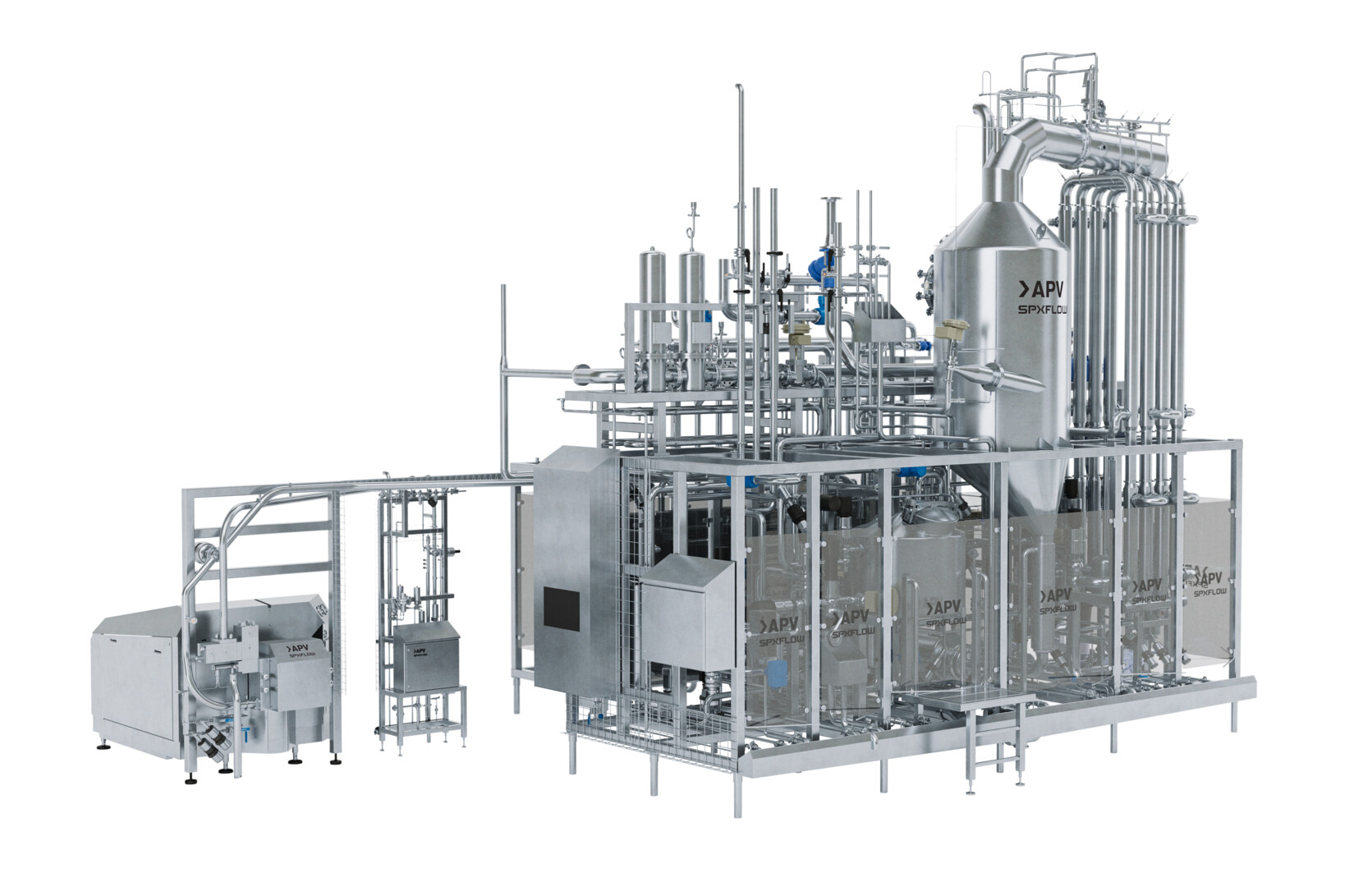

Injection UHT Systems

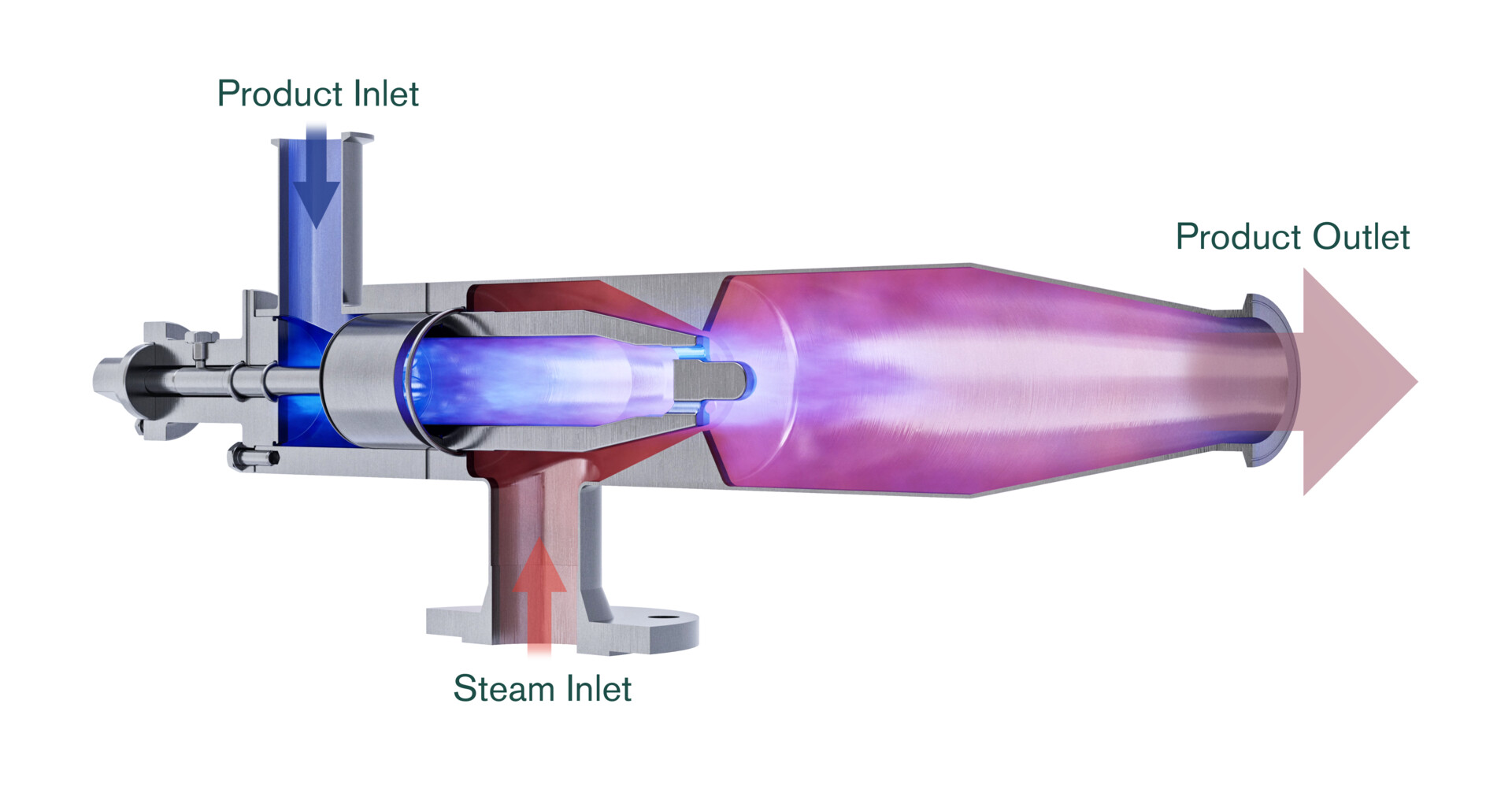

The APV® Injection UHT Systems are high-efficiency direct UHT processing solutions that use steam injection to rapidly sterilize products with minimal thermal damage. They are ideal for aseptic processing of milk, cream, flavored beverages, custard and other sensitive liquid foods. These systems help ensure long shelf life without compromising taste, color, or nutrition, all with reliable, consistent performance.