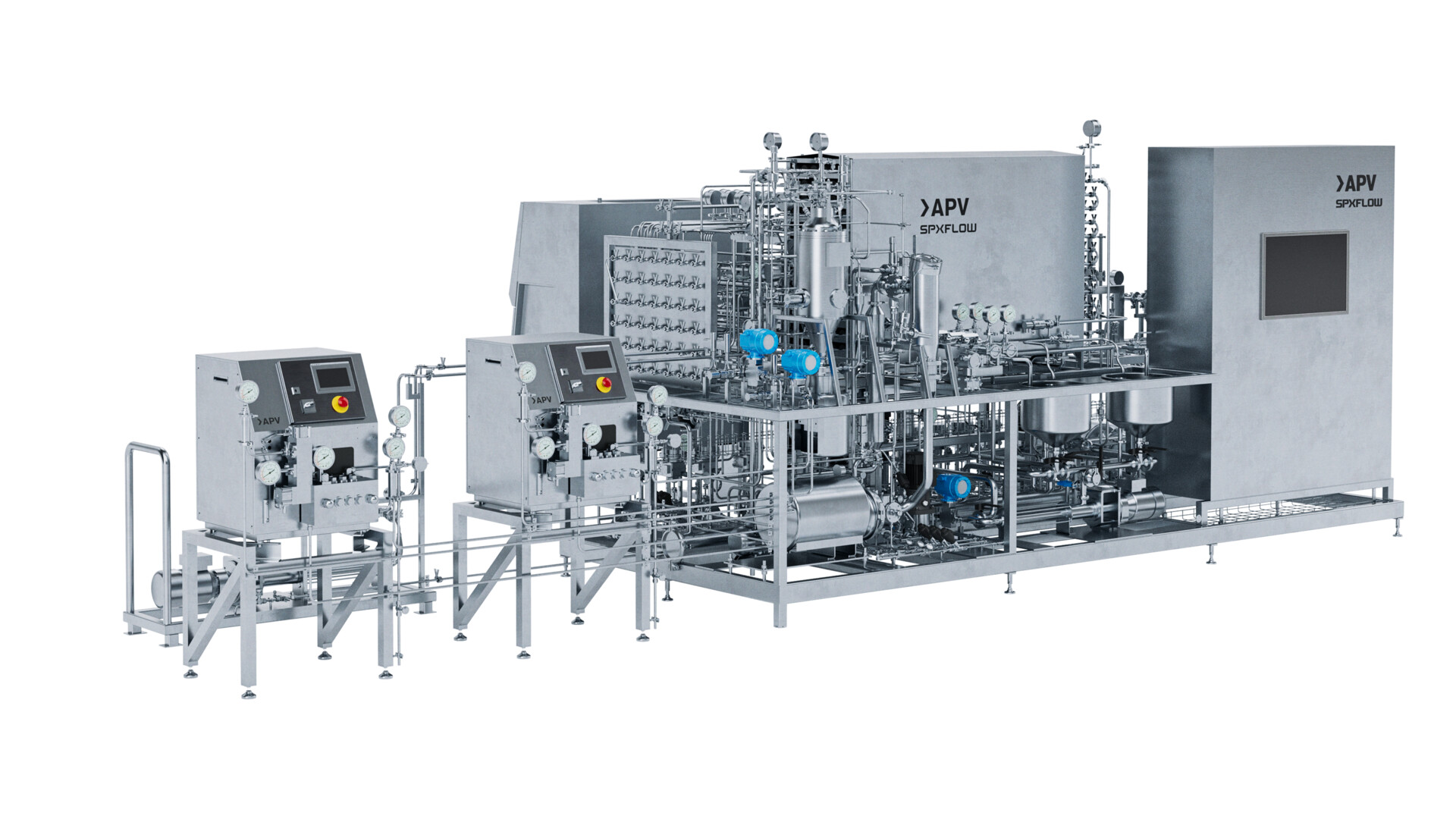

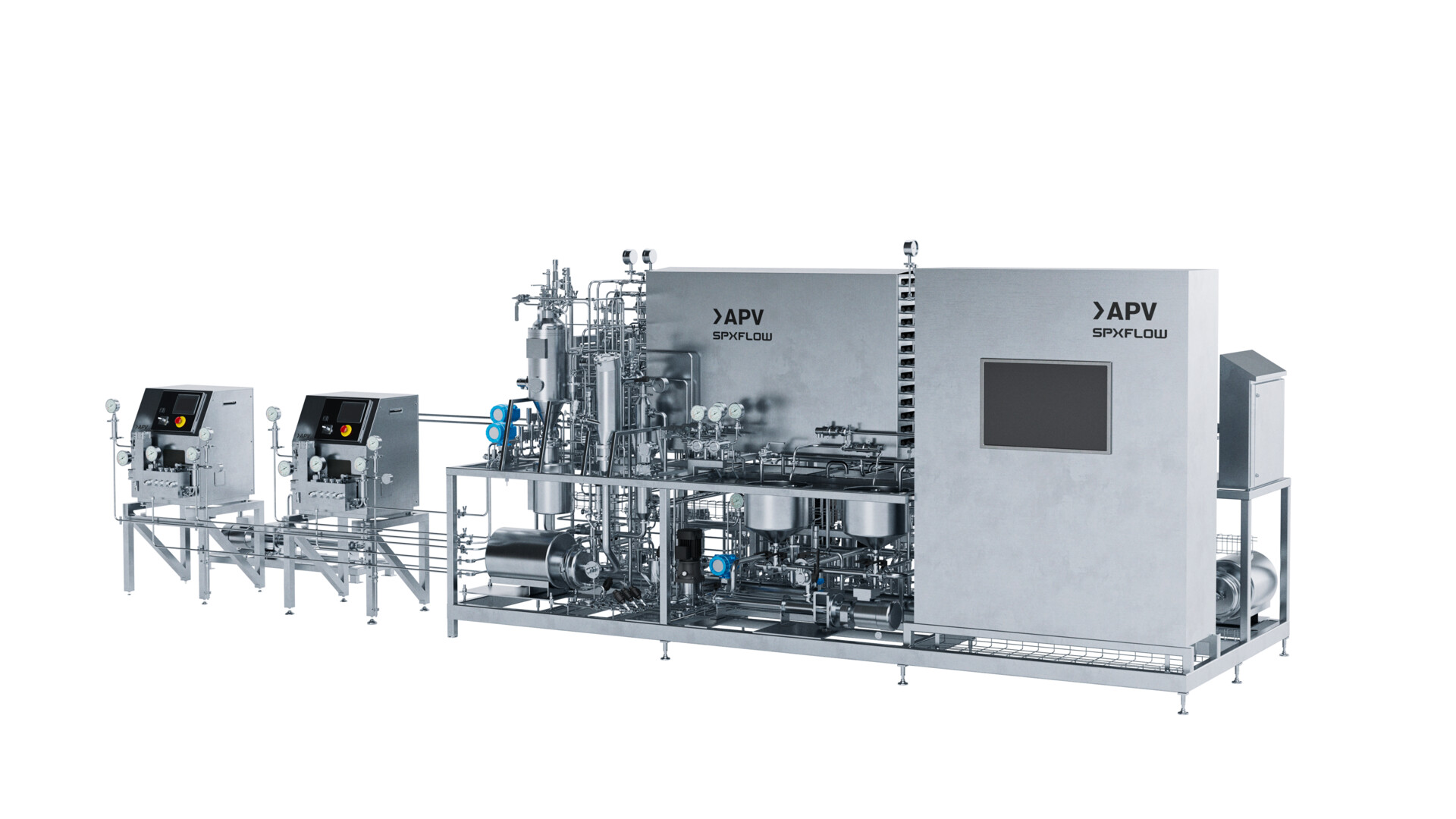

Pilot UHT Systems

APV® Pilot UHT Systems are compact, fully functional UHT processing systems designed for R&D, product development and scale-up trials. They enable manufacturers to simulate aseptic processing conditions on a small scale for testing recipes, refining processes and validating new formulations, all while minimizing product waste and development risk.