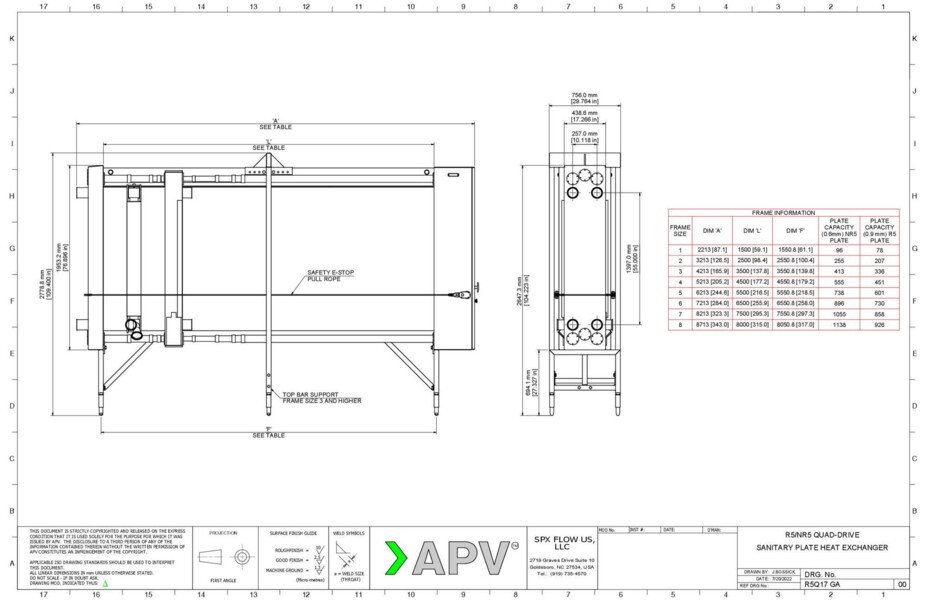

Plate Heat Exchanger Automated FastFrame™

The APV Plate Heat Exchanger Automated FastFrame means quick and easy access to plates with just the push of a button. Our electrically-driven, PLC-controlled frame is designed to provide operational savings by reducing downtime and increasing productivity. Because time is money.