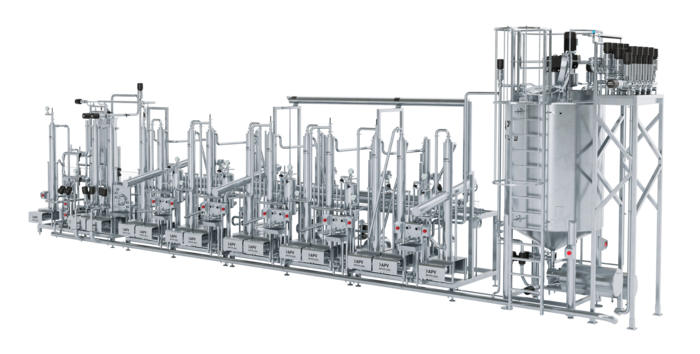

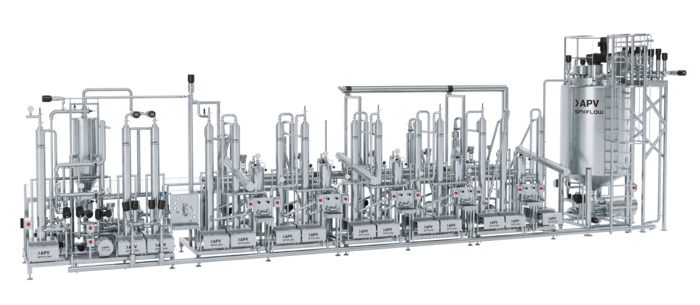

Scraped Surface Heat Exchanger UHT Systems

APV® Scraped Surface Heat Exchanger (SSHE) UHT Systems use scraped surface heat exchangers to enable ultra-high temperature processing of heat-sensitive, viscous and particulate-rich products. Designed for reliable, gentle treatment of challenging formulations, these systems ensure consistent thermal performance, smooth texture and shelf-stable results — making them ideal for aseptic processing of dairy desserts, fruit preps, baby food and sauces.