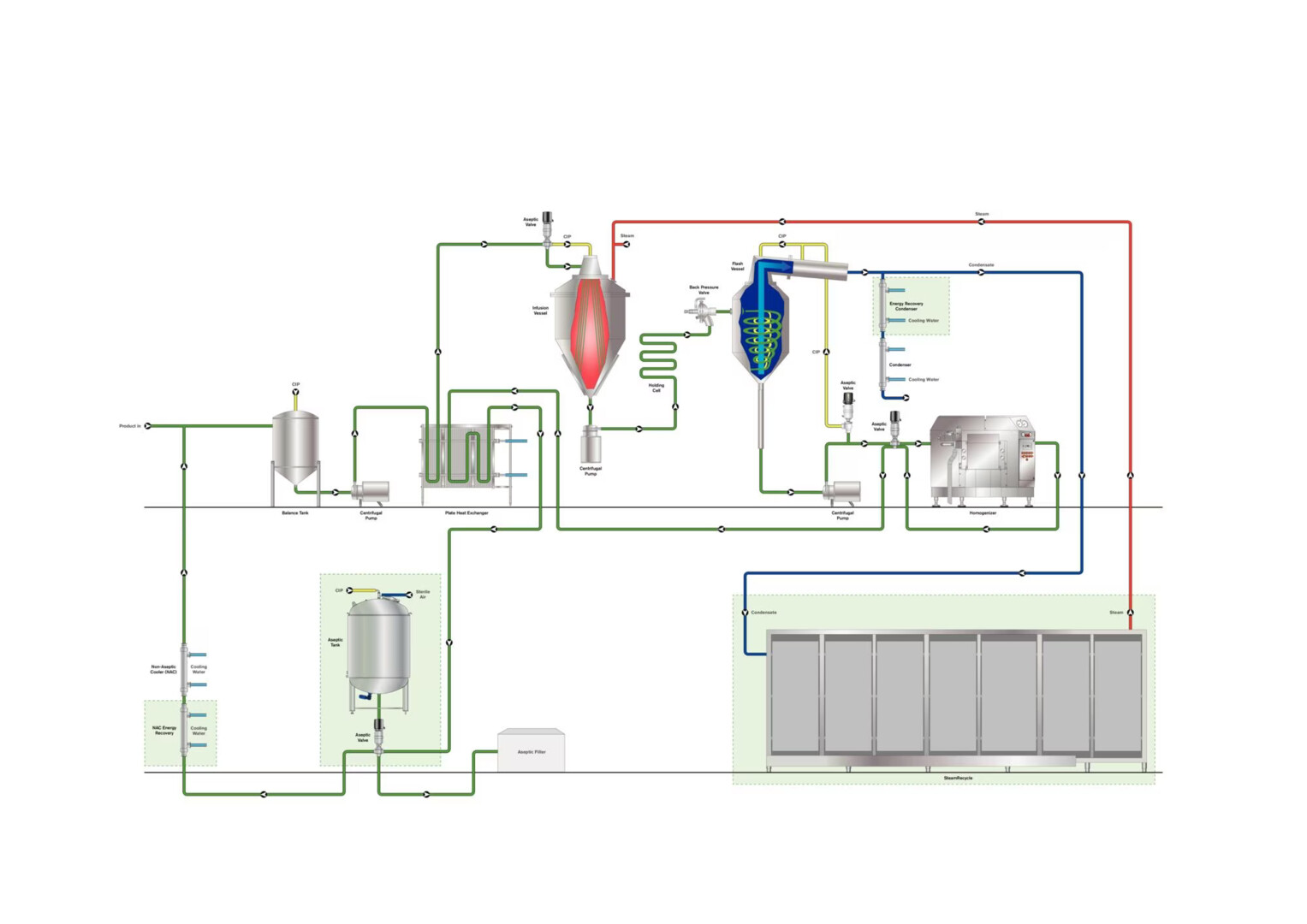

SteamRecycle System for UHT Processing

The patented APV® SteamRecycle™ System, winner of the SEAL Sustainability Award 2026 for Sustainable Product Innovation, transforms energy efficiency and sustainability in ultra-high temperature (UHT) processing. By capturing and reusing 100 percent of steam generated during the infusion heating process, SteamRecycle reduces utility consumption, operating costs, and CO₂ emissions while supporting producers’ sustainability and climate-neutrality objectives.

This recognized industry-leading technology allows manufacturers to achieve significant energy savings without compromising product quality or production throughput.