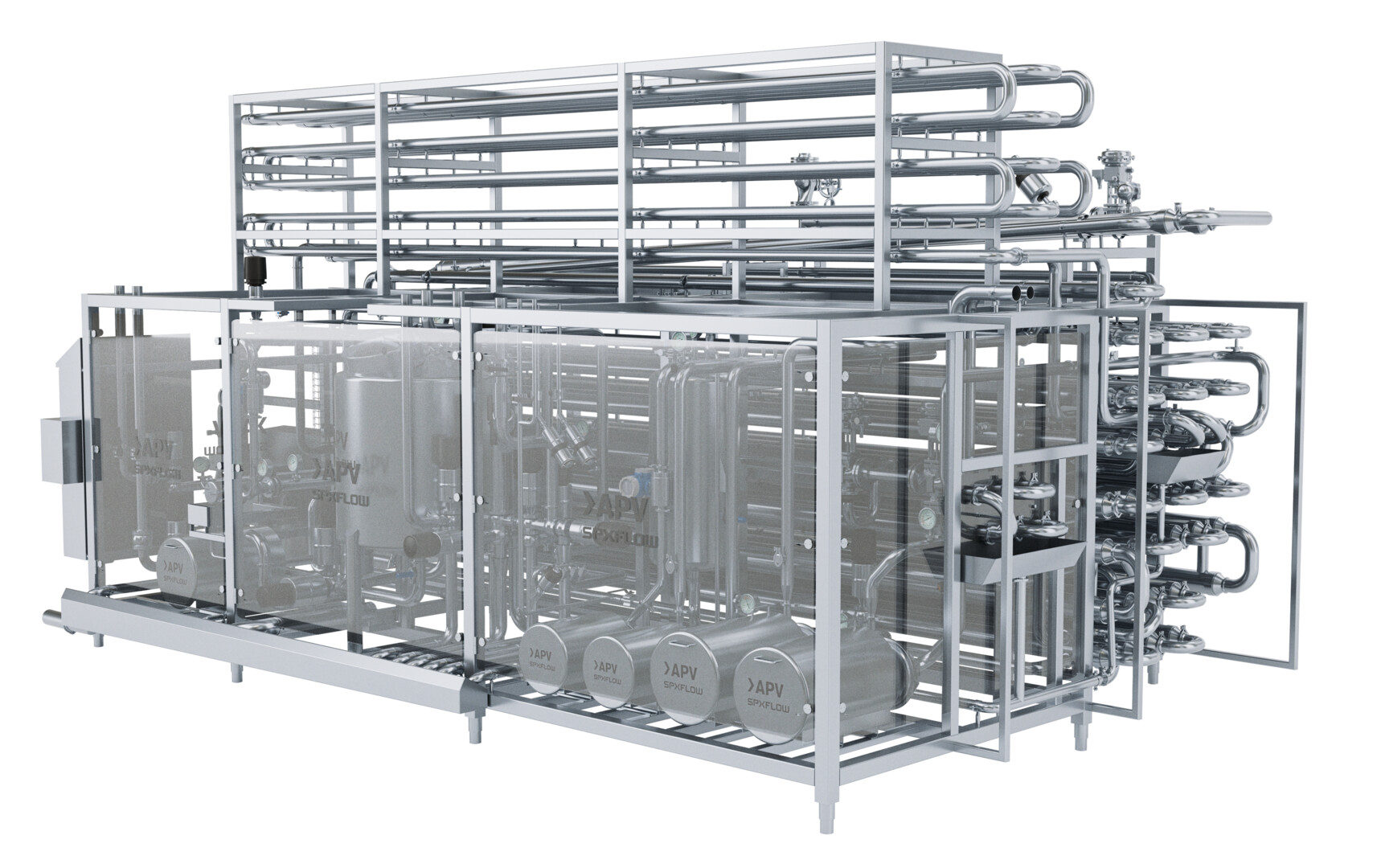

Tubular UHT Systems

APV® Tubular UHT Systems are robust, modular solutions for high-volume aseptic processing of milk, plant-based drinks, cream and other liquid foods. The systems are built for flexibility and efficiency and deliver consistent thermal treatment, long production runs and high product quality. They are available in modular or fully customized setups and support everything from basic dairy lines to complex multi-product operations.