STORIES IN THE MAKING

5 Signs It’s Time to Replace Your Plate Evaporator Gaskets

Avoid downtime. Protect your product. Know when it’s time to act.

"In food and beverage processing, system reliability protects more than production—it protects your reputation. Your APV® plate evaporator plays a critical role in concentrating ingredients like juice, broth or gelatin. But worn gaskets can jeopardize everything from product quality to plant safety.

When gaskets degrade, they don’t always fail loudly. Subtle issues can lead to major consequences: leaks, contamination, lost product or costly shutdowns.

Here are five signs it’s time to replace your evaporator gaskets—plus why choosing genuine OEM replacements from SPX FLOW is the smart, sustainable move.

1. Visible Leaks Around the Evaporator

If you notice product or CIP fluid dripping, pooling or seeping at the frame, your gaskets are likely compromised. Leaks aren’t just a maintenance issue—they signal a potential safety and contamination risk, especially in high-acid or protein-heavy applications.

Why it matters:

- Cross-contamination risks

- Lost yield and wasted resources

- Potential for escalation under heat and pressure

OEM gaskets from SPX FLOW are formulated with the right rubber compound for your process—extending gasket life and sealing integrity.

2. Pressure Drops or Reduced Capacity

A sudden drop in system pressure or increasing energy demand can signal gasket failure. Warped, swollen or misaligned gaskets may allow steam to leak into the product. This can lead to cross contamination as well as reduced capacity.

Why it matters:

- Increased utility costs

- Lower system performance

- Risk of long-term equipment strain

Gasket replacement can restore flow and thermal performance—especially after prolonged high-load conditions.

3. Gaskets Are Brittle, Cracked or Loose

Physical inspection during teardown often reveals aging gaskets. If you see cracks, loss of elasticity or slipping, your system is operating on compromised components. Continued use increases the risk of improper sealing or misalignment.

Why it matters:

- Inconsistent sealing

- Difficult plate reassembly

- Higher risk of unplanned maintenance

SPX FLOW OEM gaskets are precision-molded and chemically bonded to fit your APV evaporator plates exactly—ensuring consistent sealing and longevity.

4. Extended Run Times or CIP Exposure

Over time, even high-quality gaskets degrade under chemical and thermal stress. Each CIP cycle and extended production run adds wear. Annual or biannual replacement is often recommended depending on throughput and cleaning frequency.

Why it matters: - Reduced chemical resistance - Increased gasket compression fatigue - Unseen wear leading to failure

SPX FLOW offers predictive replacement planning to help you avoid downtime and optimize maintenance schedules.

5. No Record of Last Gasket Replacement

If you're unsure when gaskets were last replaced, you're running a critical process without visibility. This is common with inherited systems or lapsed documentation.

Why it matters:

- Missed replacement windows

- Higher risk of undetected failures

- Uncertain system reliability

A proactive gasket replacement—using SPX FLOW parts—restores confidence and performance predictability.

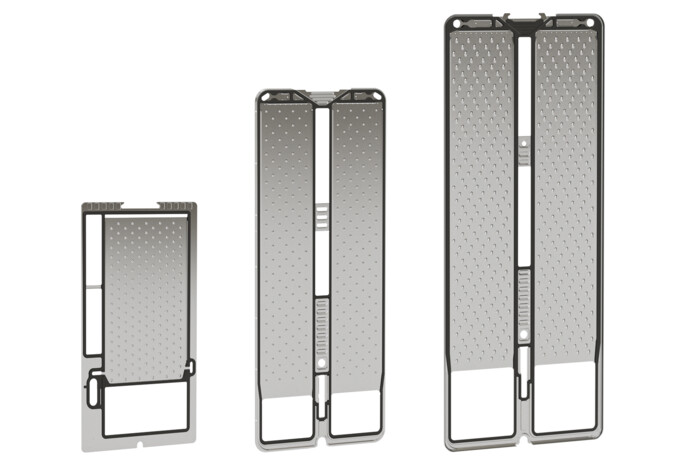

Why OEM Gaskets from SPX FLOW?

Generic gaskets may fit, but they’re not engineered for your APV system. Only SPX FLOW OEM gaskets are:

- Designed specifically for APV plate evaporators - Made from FDA-compliant food-grade materials - Tested in demanding applications including citrus, broth and gelatin

Backed by warranty and technical support

Start with Confidence

Don’t wait for a leak to become a shutdown. When performance matters, SPX FLOW solution makers are ready to help.

Contact Us to learn more about OEM gasket kits for your APV plate evaporator.