STORIES IN THE MAKING

Engineered for Demanding Conditions: Bran+Luebbe Chemical Injection Systems for Oil and Gas

Oil and gas operations are defined by extremes—temperature, pressure, location, and volatility. From offshore platforms battling sea spray and space constraints to onshore fields in remote, rugged terrains, operators face constant challenges. To maintain 24/7 production, they rely on systems that deliver consistent performance without fail. Among these, chemical injection systems (CIPs) play a vital yet often underappreciated role across the oil and gas value chain.

At SPX FLOW, we design chemical injection solutions that meet this challenge head-on. Our Bran+Luebbe brand delivers compact, reliable, and high-performance systems trusted by industry leaders worldwide.

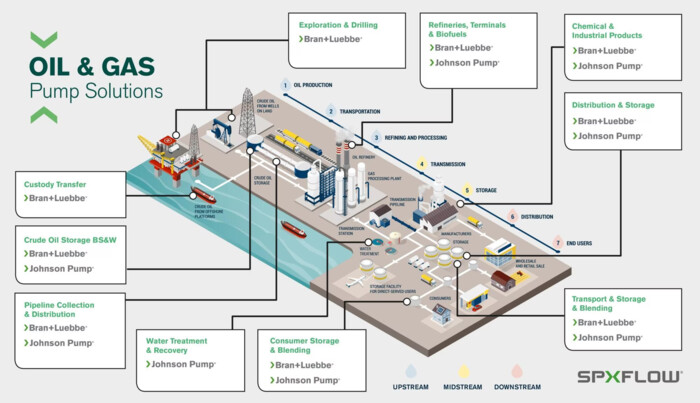

Supporting the Full Oil & Gas Lifecycle

From exploration and drilling to transport, storage, refining, and maintenance, chemical injection systems are essential for ensuring fluid integrity, asset longevity, and production efficiency. Each installation presents unique requirements based on location, chemical type, process conditions, and output targets.

Bran+Luebbe supports this complexity with proven experience in both standard and fully customized CIPs. Whether it’s a single-pump skid or a multi-pump system with integrated tanks and controls, our solutions are engineered to meet application-specific needs with precision.

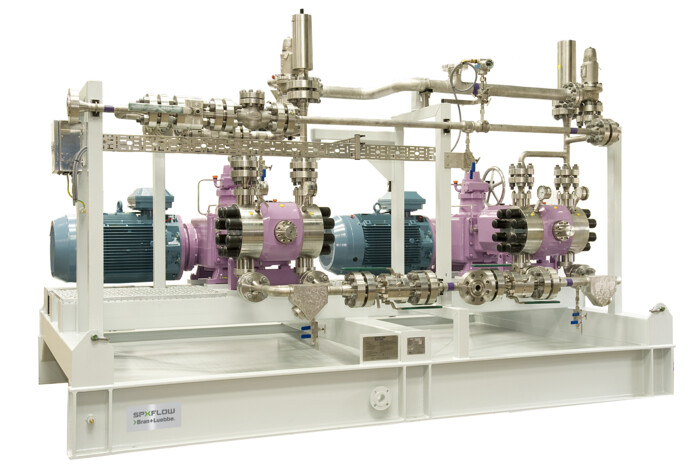

Integrated Expertise from Design to Delivery

Every Bran+Luebbe chemical injection skid is custom-engineered using advanced 3D design tools and built to the highest industry standards. Each package includes not only pumps but also pipework, valves, instrumentation, and controls, fully integrated and tested as a system.

Our customers benefit from decades of experience delivering to EPCs, end users, and operators across the globe. We understand the environmental, spatial, and operational constraints faced in the field and design with those realities in mind.

Compact Innovation: The Novados DADD Pump

At the heart of many Bran+Luebbe systems is the NOVADOS Double-Acting Double Diaphragm (DADD) metering pump. This innovative design delivers the capacity of a duplex pump in a significantly smaller footprint, making it ideal for space-limited environments such as offshore platforms, FPSOs, and wellhead installations.

- One head, double the output: Delivers performance comparable to dual-head systems

- Reduced weight and footprint: Minimizes structural loading and eases installation

- Accurate, leak-free operation: Ideal for hazardous and high-value chemicals

- Energy efficient: Low power consumption, especially in continuous-duty applications

The DADD pump supports retrofitting of existing systems. A single-acting diaphragm pump can be upgraded to a double-acting configuration with minimal pipework modification, preserving the original footprint while increasing capacity.

Trusted for Critical Applications

Bran+Luebbe diaphragm pump systems support precise chemical injection throughout the oil and gas process.

Applications include:

- Corrosion inhibitors

- Scale inhibitors

- Antifoam agents

- Demulsifiers

- Glycol and methanol

- Polymers for Enhanced Oil Recovery (EOR)

In polymer injection, the DADD pump’s gentle handling preserves polymer chain integrity, critical for maximizing EOR effectiveness and minimizing waste of high-cost materials.

Designed for Performance, Built for Uptime

Compared to duplex or plunger-style pumps, the DADD configuration offers fewer components, which means lower maintenance and increased reliability. While plunger pumps are effective, they lack the leak protection of a diaphragm design. Duplex pumps add bulk and complexity. The DADD pump offers a streamlined alternative without compromising performance.

To enhance reliability even further, SPX FLOW offers Novalink, a digital diagnostic tool that provides real-time condition monitoring. Whether inline or at-line, Novalink enables predictive maintenance, reduces emergency downtime, and extends the life of critical components.