STORIES IN THE MAKING

How Evaporators Help You Achieve Vibrant Natural Colors in Food Processing

Color drives appeal. Whether it’s a rich berry hue or the warm glow of turmeric, natural colors play a critical role in how consumers perceive flavor and freshness. For food manufacturers aiming to replace artificial dyes with plant-based alternatives, maintaining color strength during processing is essential. This is where evaporation technology makes a measurable difference.

Preserving Color Through Gentle Processing

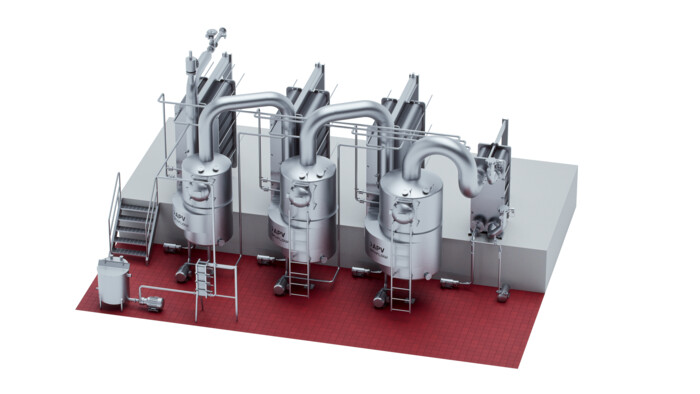

Natural colors are often heat-sensitive and prone to degradation when exposed to harsh processing conditions. APV falling film evaporators are engineered to minimize thermal stress by operating under vacuum, enabling lower boiling temperatures. This preserves pigment integrity—so red beet extracts stay bold, and spinach chlorophyll retains its natural green.

Improving Concentration Without Compromise

To meet commercial demands, natural color solutions often need to be concentrated before formulation. APV evaporators provide efficient water removal while maintaining the sensory and functional properties of the color source. The result is a concentrated product with high color density and reduced transport and storage costs.

- Low residence time minimizes exposure to heat

- Consistent performance supports color uniformity across batches

- Custom configurations fit a range of ingredients from fruit to botanicals

Supporting Clean-Label Formulations

As consumers continue to demand shorter ingredient lists and natural alternatives, food producers are under pressure to deliver clean-label solutions without sacrificing visual appeal. APV evaporators support this goal by enabling the production of natural colorants that meet both regulatory and sensory standards.

A Reliable Path to Natural Color Innovation

Natural color production comes with challenges—from raw material variability to thermal sensitivity. APV evaporation systems give processors the control and predictability they need to produce vibrant, shelf-stable colors without synthetic additives.

When your product’s first impression is its appearance, make color your competitive edge.

Contact a solution maker to explore how APV evaporation systems will support your natural color production goals.