STORIES IN THE MAKING

Precision, Protection, and Performance:

Understanding Bran+Luebbe Metering Pumps

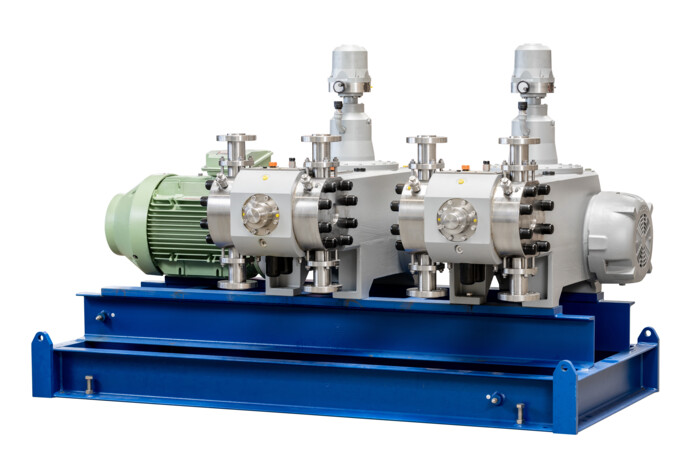

In industries where precision fluid handling is critical, from oil and gas to pharmaceuticals, metering pumps serve as the heartbeat of process integrity. At SPX FLOW, we understand that reliable dosing isn’t just a feature; it’s a necessity. That’s why the Bran+Luebbe brand metering pump portfolio is engineered with advanced functionality to meet the exacting demands of modern industrial operations.

What Is a Metering Pump?

Also referred to as dosing pumps, metering pumps are positive displacement devices designed to deliver exact volumes of fluid under controlled conditions. These pumps operate by drawing a fixed volume of fluid into a chamber during each cycle and then discharging it precisely. The flow rate is finely adjustable by modifying the stroke length and frequency, offering a high degree of dosing accuracy.

Advanced Bran+Luebbe models take precision even further with support for remote control and integration into digital process automation frameworks. This capability not only enhances dosing accuracy but also streamlines system-wide performance monitoring and control—essential for industries that demand traceability, repeatability, and efficiency.

Types of Bran+Luebbe Brand Metering Pumps

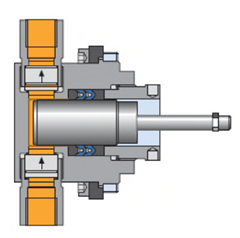

Plunger Metering Pumps: Reliable in Clean Conditions

Bran+Luebbe plunger pumps operate through direct mechanical displacement via a reciprocating piston. These pumps are ideal for clean, low-viscosity fluids where high pressure is required but chemical aggressiveness is low. You’ll find them at work in food and beverage dosing, hygienic personal care processes, and other non-hazardous liquid applications.

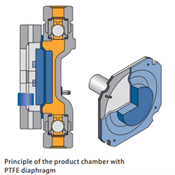

Diaphragm Metering Pumps: Safety and Compatibility

Diaphragm metering pumps isolate the pumped fluid from moving parts using a PTFE or stainless steel diaphragm, making them highly resistant to corrosion and leakage. Available in two actuation types:

Mechanically Actuated Diaphragm Pumps

Mechanically Actuated Diaphragm Pumps offer an economical, low-maintenance solution for routine tasks in water treatment and general chemical processing.

Hydraulically Actuated Diaphragm Pump

Hydraulically Actuated Diaphragm Pumps deliver high accuracy, overload protection, and leak-free performance. These are the go-to solutions for high-stakes dosing in oil refining, specialty chemicals, and pharmaceuticals.

With options including corrosion-resistant materials like Hastelloy® and titanium, these pumps are built to withstand even the harshest fluids.

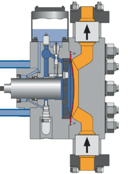

Double-Acting Double Diaphragm Pumps: Engineered for Continuity

Bran+Luebbe’s advanced double-acting double diaphragm (DADD) pumphead is purpose-built for high-precision applications in demanding process environments. Featuring two PTFE diaphragms that operate in synchronized, out-of-phase motion—one performing suction while the other executes discharge—this design produces a nearly continuous, pulse-free flow. It’s a superior solution for applications where flow consistency is critical and pulsation dampeners are impractical or undesirable.

Advantages in Process Control:

- Continuous, pulse-free dosing ensures superior accuracy for sensitive or finely tuned processes.

- Enhanced safety by fully isolating hazardous or toxic fluids, protecting both product and personnel.

- Reduced footprint provides space efficiency without compromising performance—an asset in compact installations.

- Proven reliability in challenging sectors including oil and gas, petrochemical processing, and specialty chemical manufacturing.

This pumphead design not only supports stable, uninterrupted fluid delivery but also reduces mechanical stress on system components, extending service life and reducing maintenance demands.

Integrated Innovation and Application Versatility

Whether it's catalyst dosing in petrochemical production or sterile metering in life sciences, Bran+Luebbe pumps integrate seamlessly into your automation systems. With optional automated operation, rugged designs, and materials selected for durability and compliance, these pumps are tailored for performance in environments where failure isn’t an option.

Why SPX FLOW?

Every pump we deliver comes with the backing of SPX FLOW’s global expertise, application engineering, and service infrastructure. Our commitment extends beyond product delivery; we partner with customers through maintenance contracts, diagnostics, and performance optimization services to ensure uptime and process continuity.