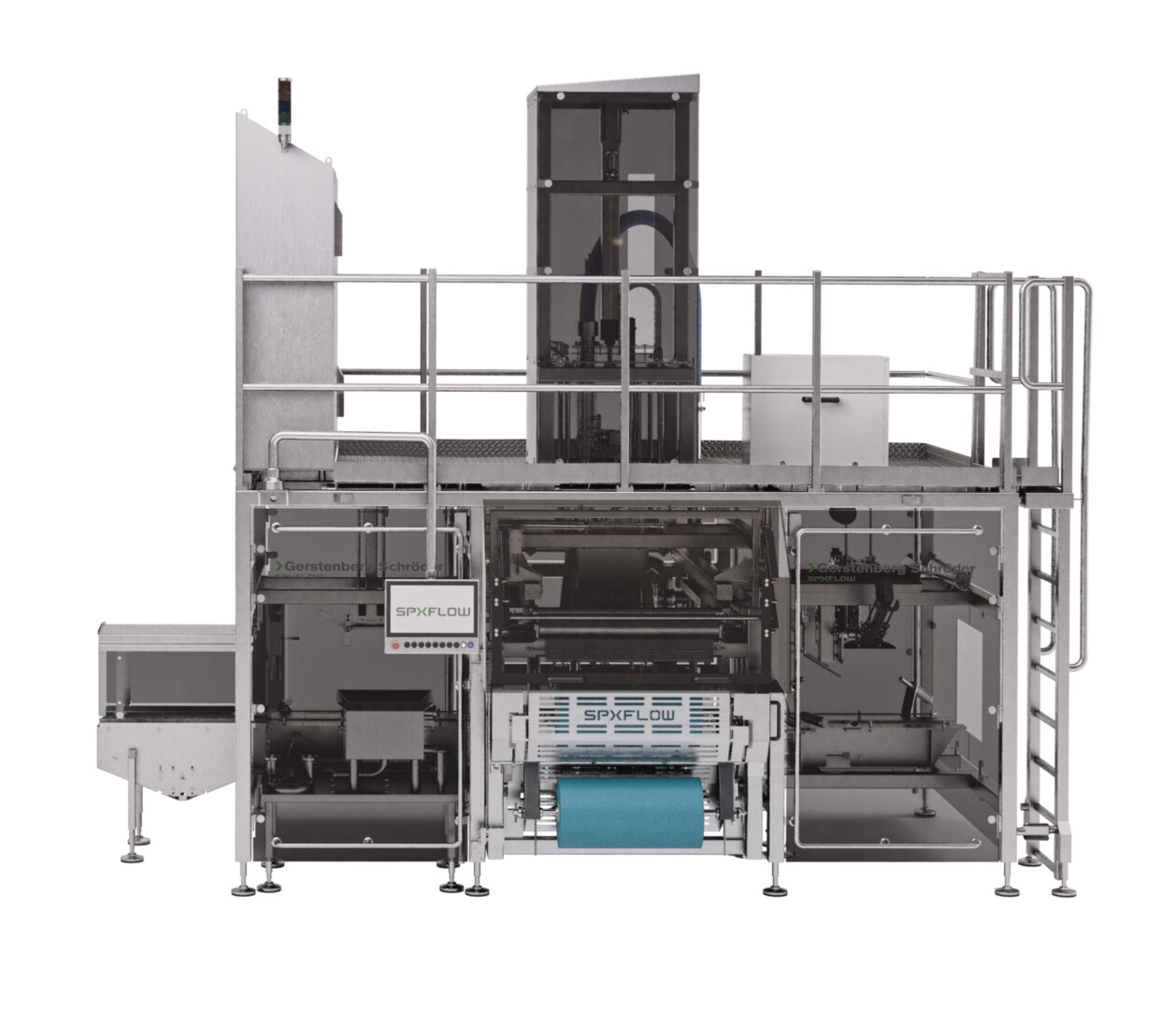

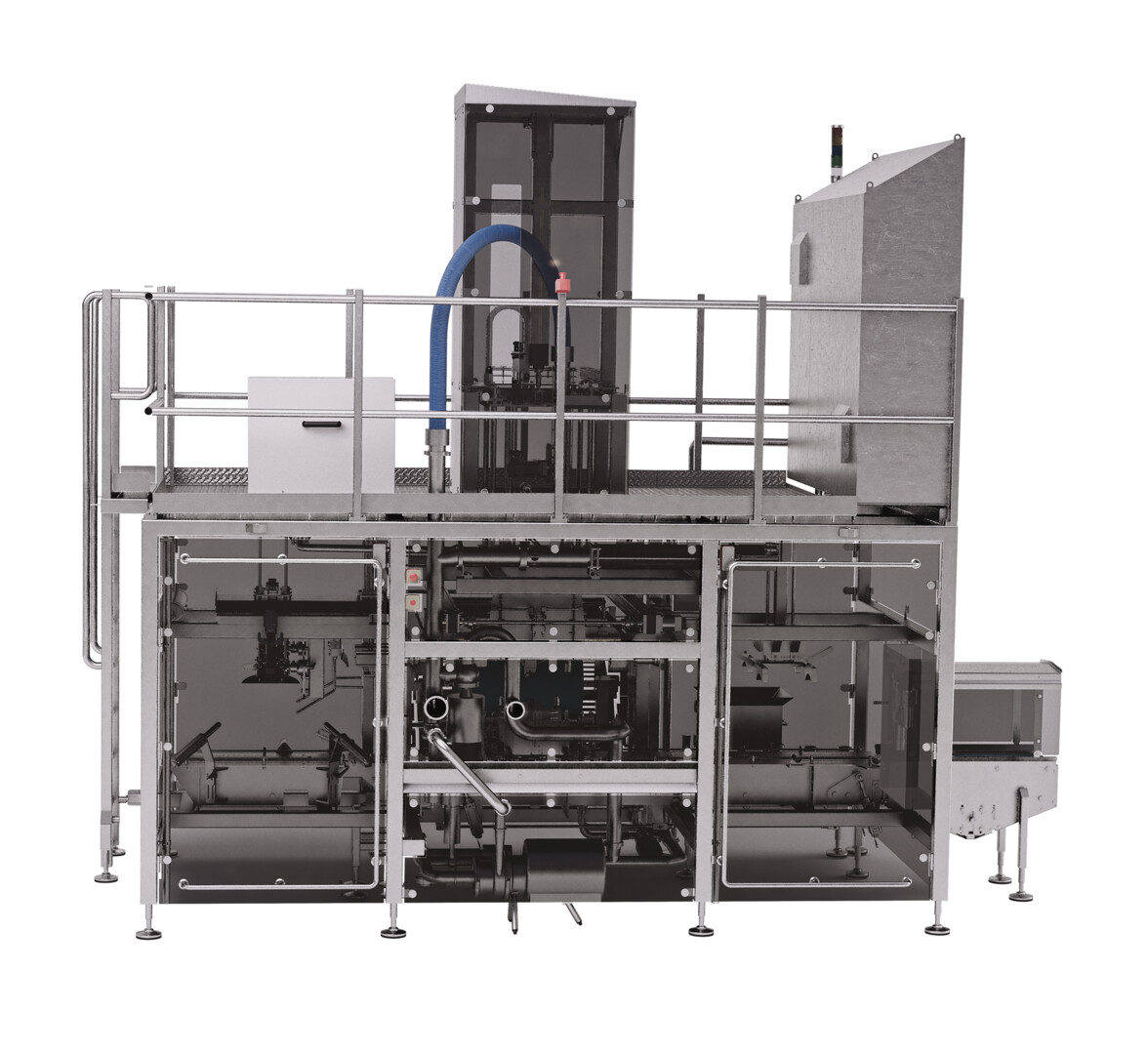

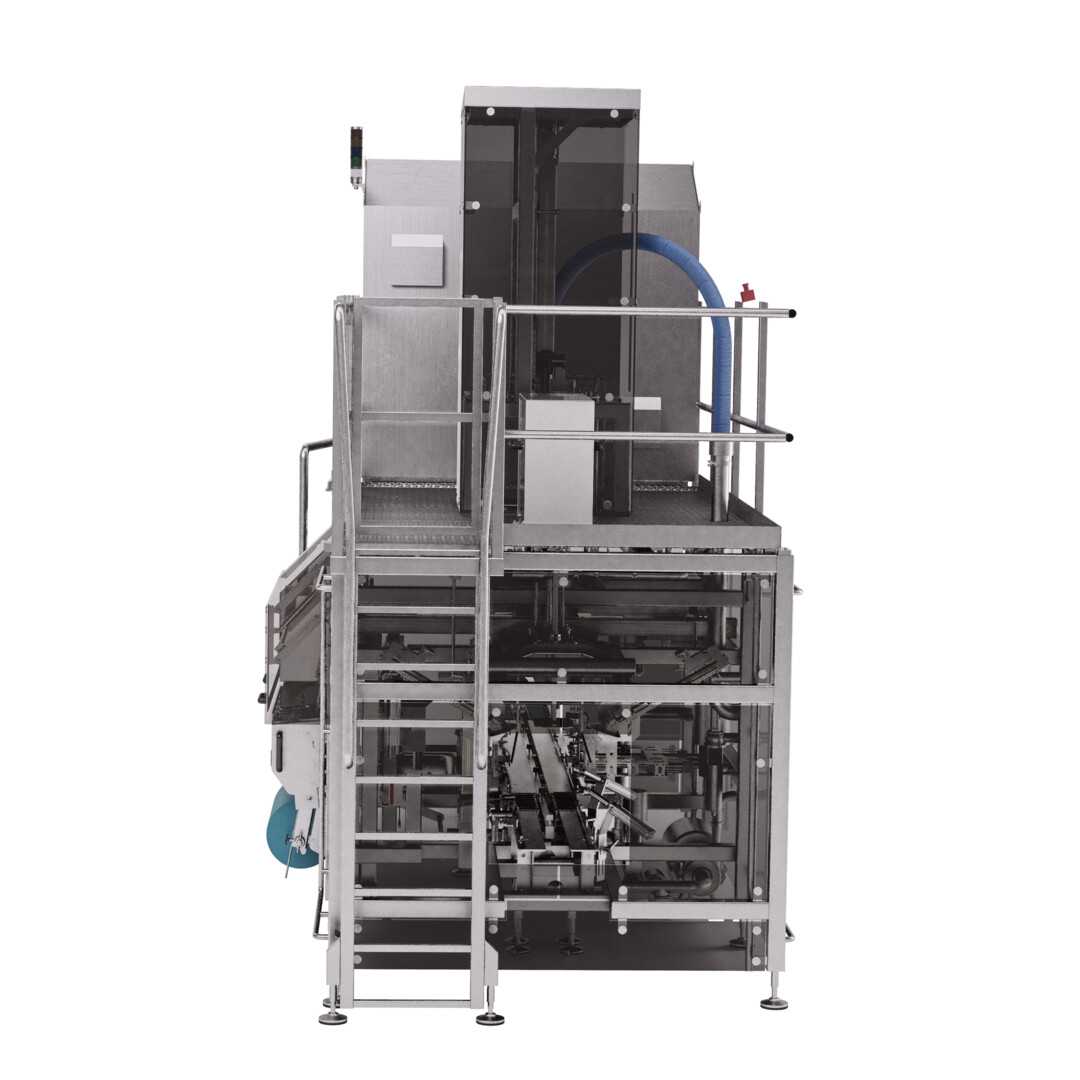

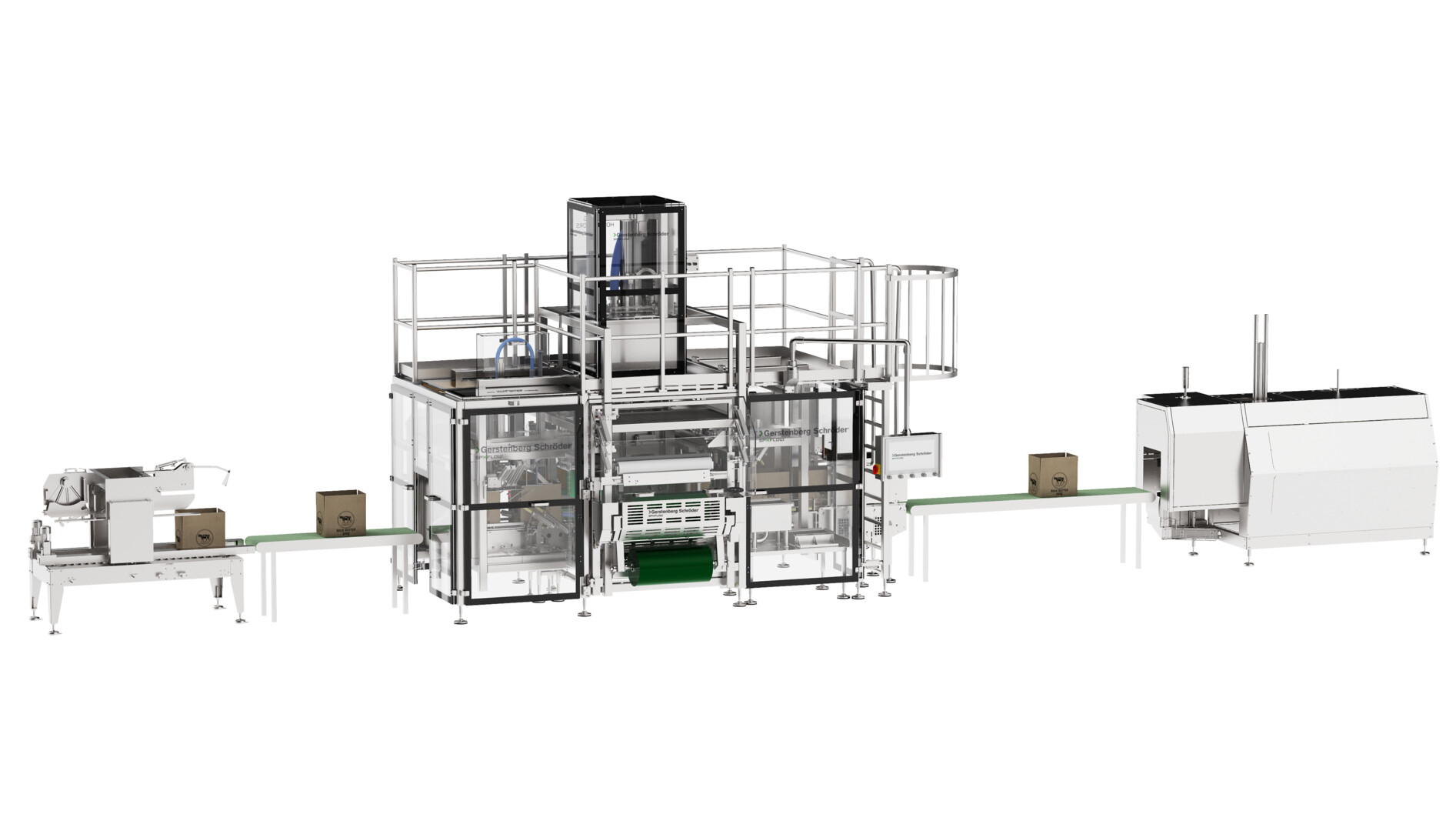

Butter Bulk Packer type BP5000

Designed to meet the latest operator safety and food hygiene standards, the Gerstenberg Schröder® Butter Bulk Packer provides an efficient, fully automatic packaging solution for butter and other crystallized products. Compatible with carton sizes from 10 kg to 25 kg, it is ideal for butter, crystallized vegetable fat, anhydrous milk fat (AMF), dairy spreads, pastry and more, ensuring precision, hygiene and high-capacity performance in butter processing.