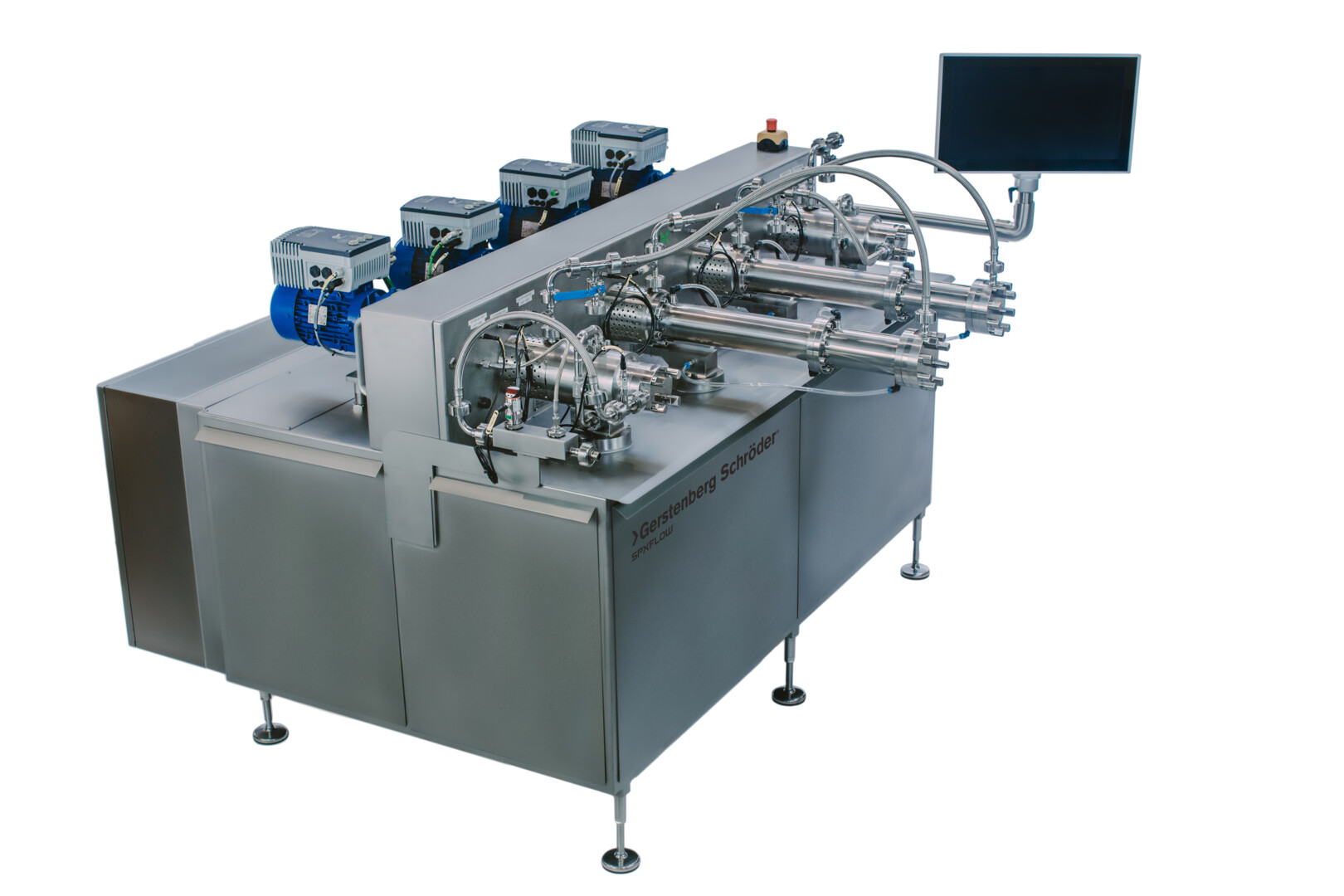

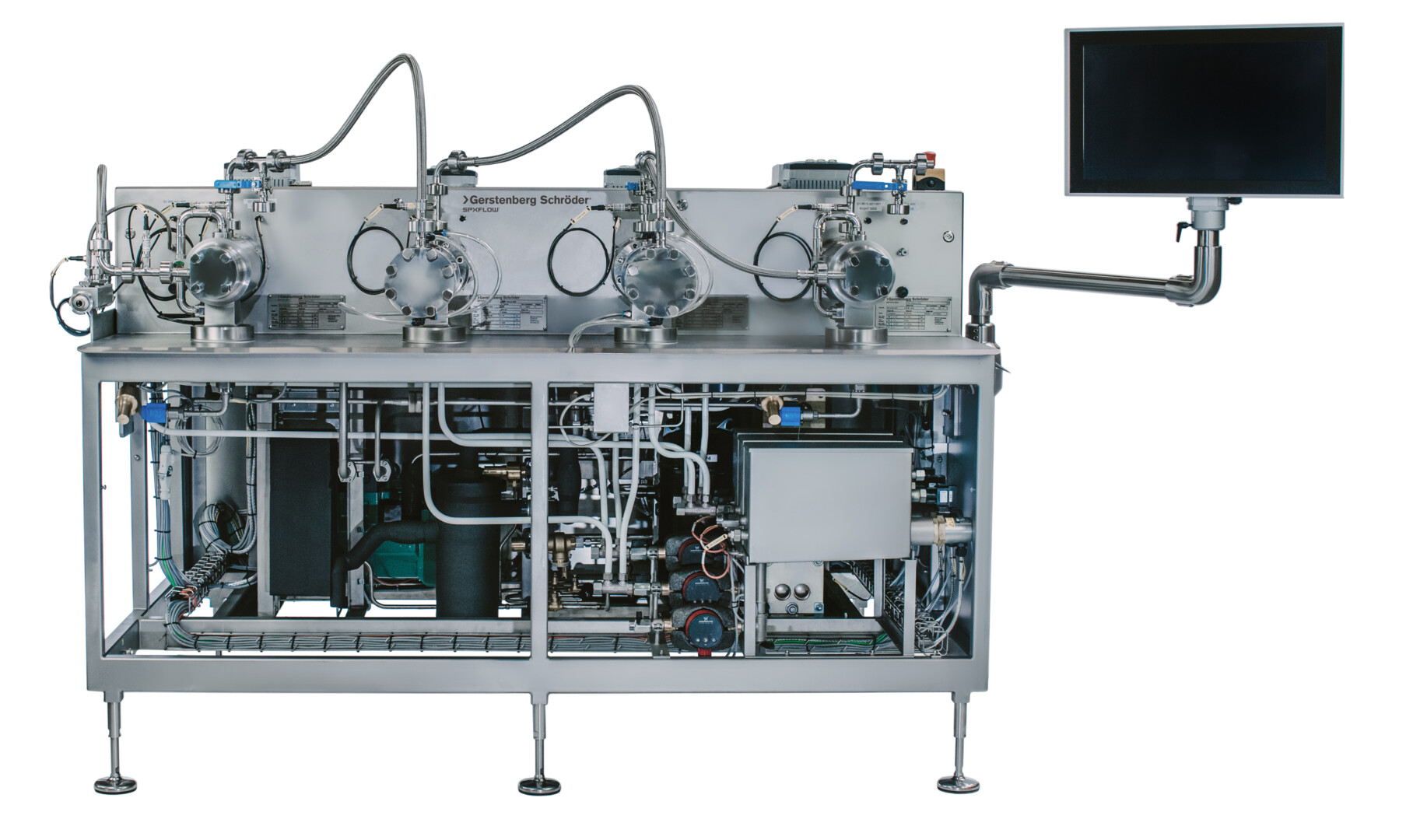

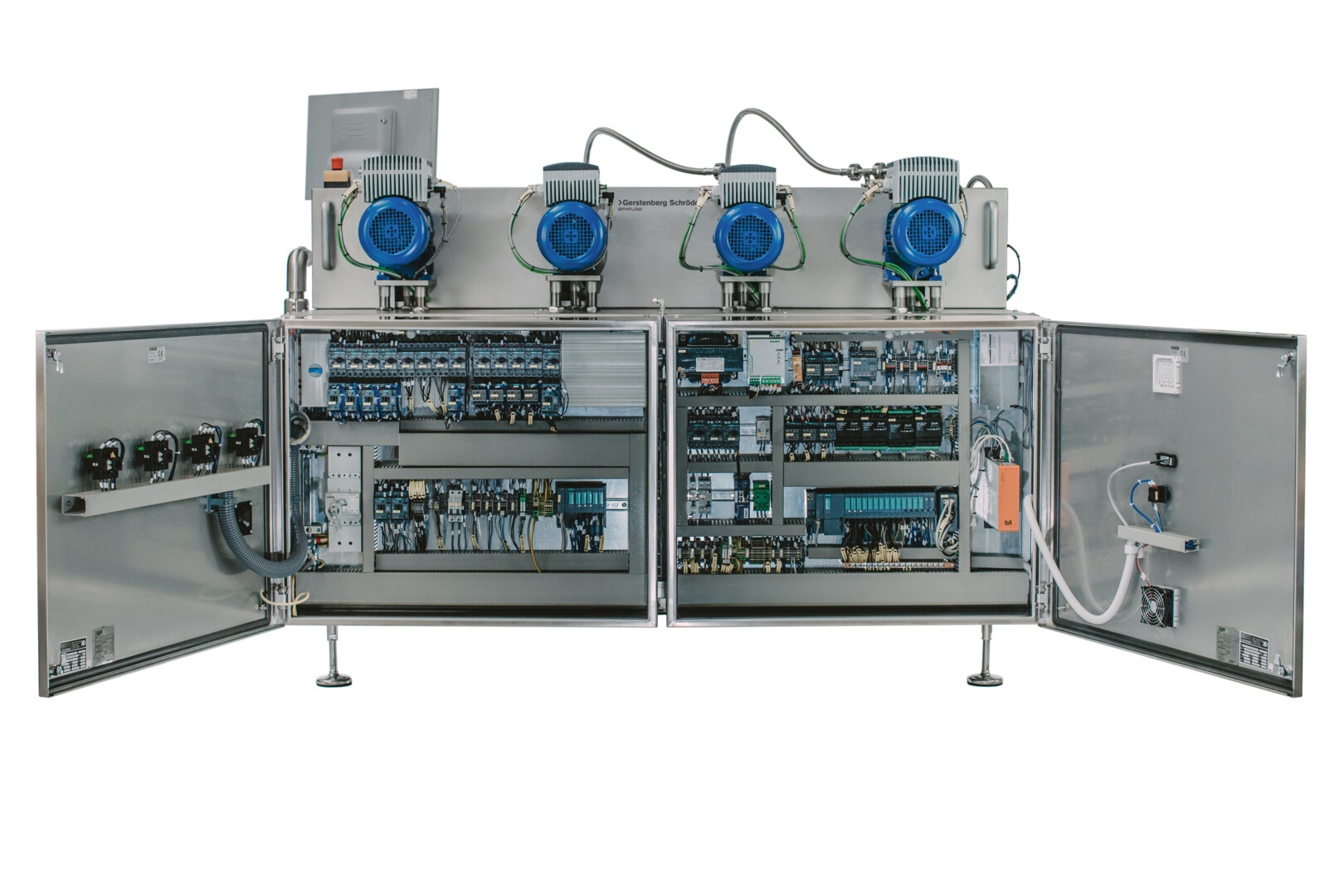

Nexus - Pilot Plant for Fat Crystallization - Small-Scale Scraped Surface Heat Exchangers

The Gerstenberg Schröder Nexus Pilot Plant is a highly flexible and modular system designed to test various high-viscosity applications in the dairy, fats and oils, and processed food industries. It provides the opportunity to process small-scale samples under the exact same conditions as those in large-scale production facilities. The Nexus Pilot Plant is designed for high efficiency and low energy consumption, utilizing environmentally friendly and highly efficient CO2 as a refrigerant.