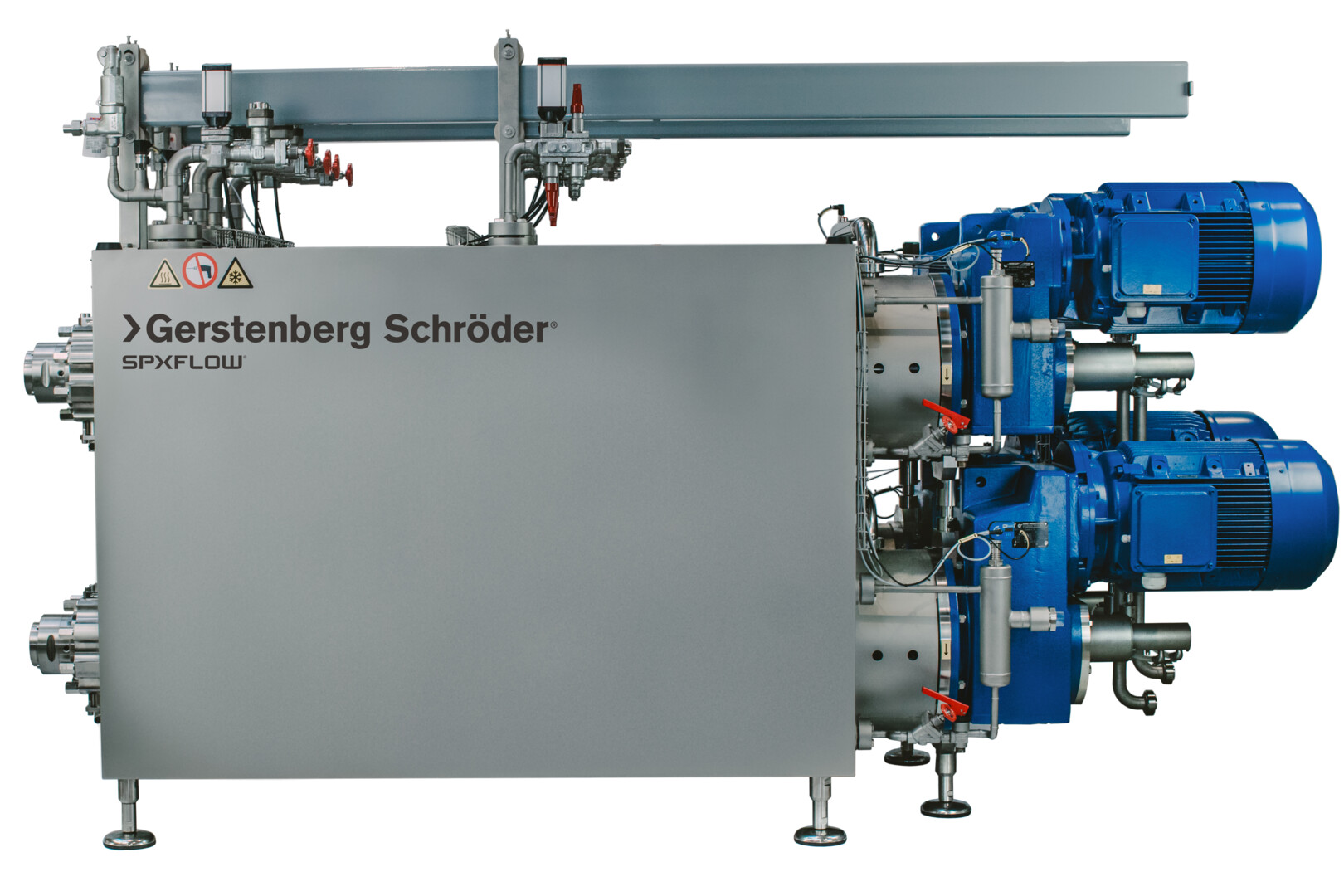

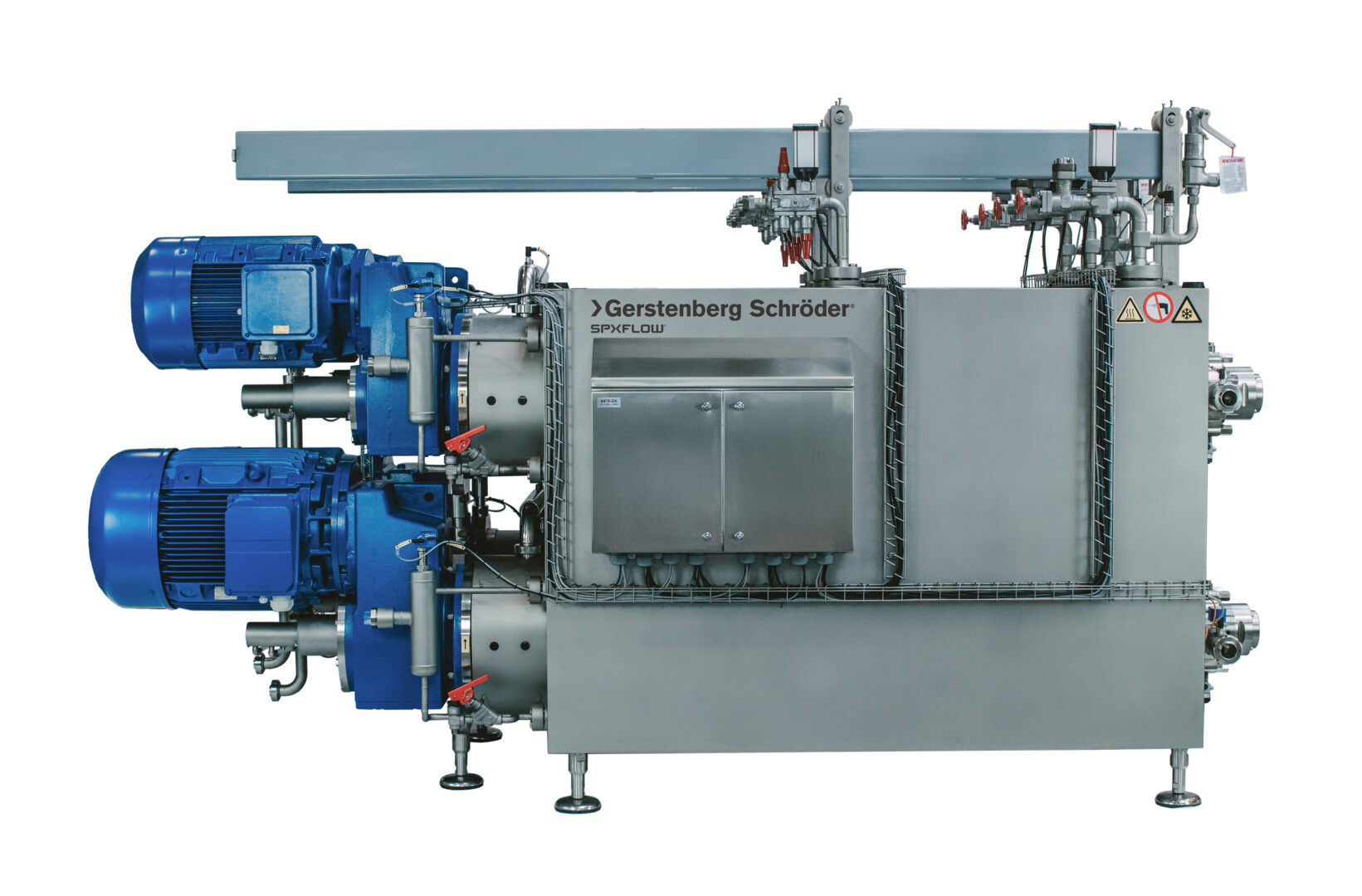

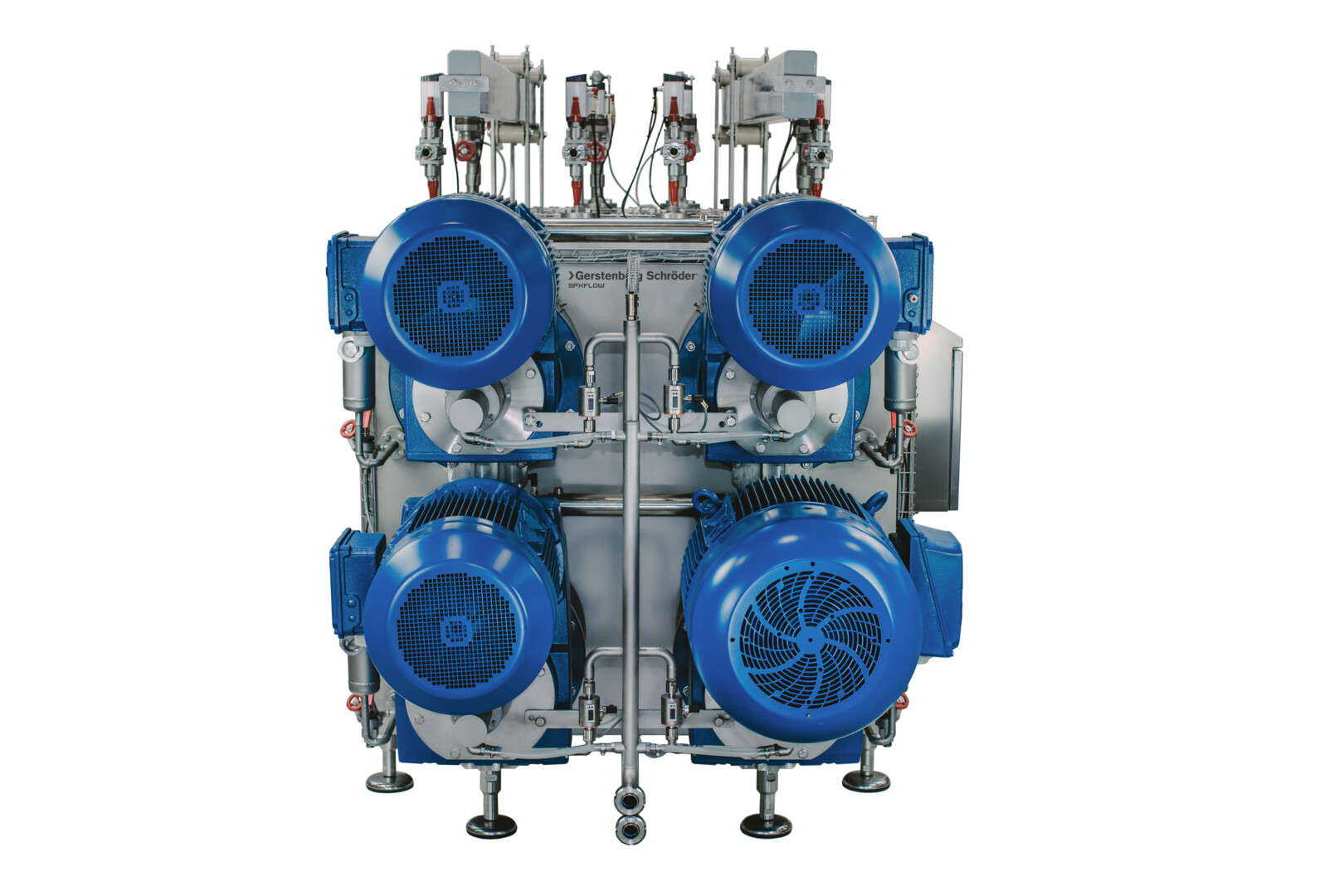

Nexus® - Scraped Surface Heat Exchangers

Nexus is a compact, high-capacity, high-pressure scraped surface heat exchanger designed for various high-viscosity applications within the Fats & Oils industry. It is designed for low energy consumption using CO2 as the highly efficient cooling medium, but it can also be used with the traditional ammonia NH3. It provides high crystallization performance, minimal downtime, and easy maintenance.