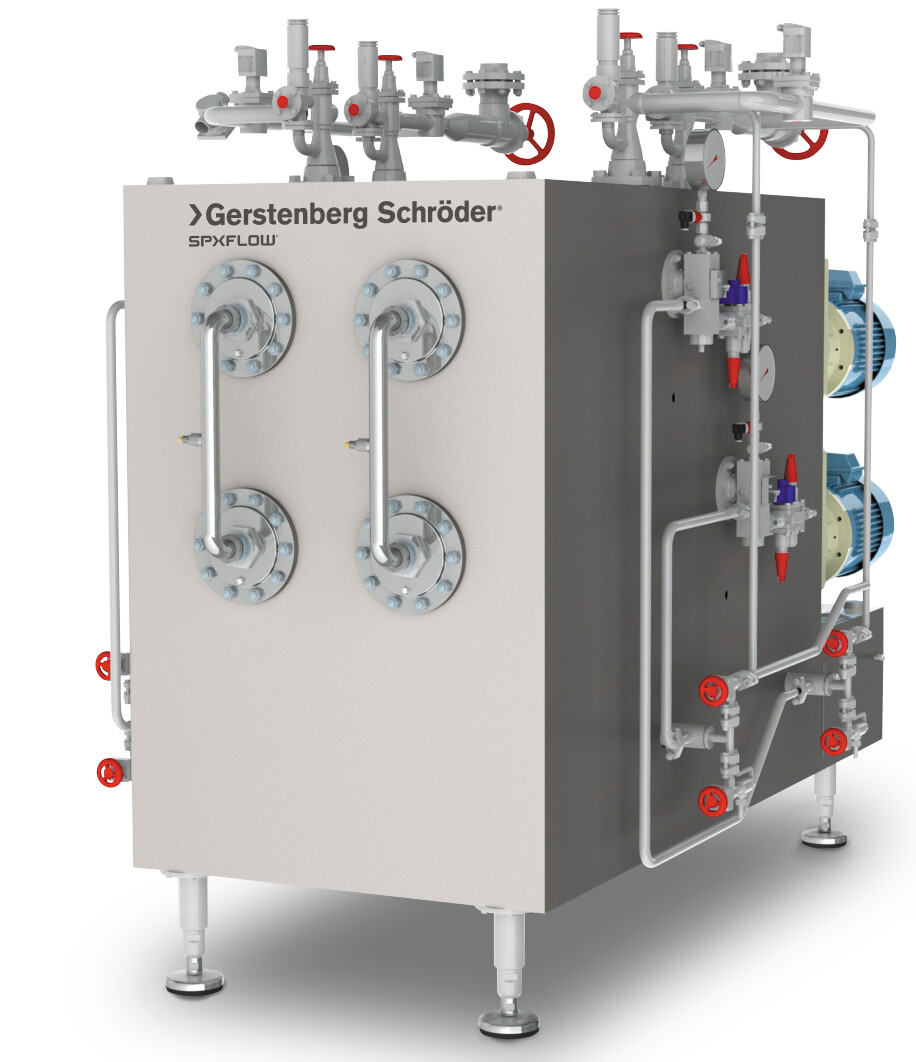

Perfector® 150 - Scraped Surface Heat Exchangers

The Gerstenberg Schröder Perfector® 150 is a compact, medium-capacity, high-pressure scraped surface heat exchanger designed exclusively for the chilling of semi-liquid fillings such as shortening and soft table margarine. It provides high crystallization performance, minimal downtime, and easy maintenance.