Products

- Analyzers

- Automation Systems

- Butter Equipment

- Centrifuges

- Cleaning-in-Place Systems

- Deareators

- Draught Regulators

- Evaporators

- Fat Crystalization Equipment

- Filters & Strainers

- Fluid Bed Dryers

- Heat Exchangers

- Homogenizers

- Membrane Filtration Systems

- Microparticulation Systems

- Mixers & Agitators

- Pasturization Systems

- Pigging Systems

- Plumbing Products

- Pumps

- Recreational Marine Products

- Recreational Marine Pumps

- Spin Flash Dryers

- Spray Dryers

- UHT Systems

- Valves

- Adhesives & Sealants

- Automotive Heating System

- Baby Food

- Bakery Filing Cream

- Beer, Cider, Wine & Spirits

- Biodiesel

- Boats & Watercraft

- Building Infrastructure

- Butter & Spreads

- Cement

- Cheese

- Chocolate

- Coffee & Tea

- Condiments, Sauces & Soups

- Cosmetics

- Dairy Powders

- Ethanol

- Flavors & Fragrances

- Fruit Juice

- Fuel Supply System

- Hair, Nail & Skin Care Products

- Ice Cream

- Inorganic Chemicals

- Margarine & Shortening

- Meat & Animal-Based Proteins

- Milk & Cream

- Neutralization

- Nutraceuticals

- Oral Care

- Paints & Coatings

- Petrochemicals

- Pipelines

- Plant-Based Food & Beverages

- Plastic & Resins

- Refinery

- Soft Drinks

- Solvents & Solutions

- Specialty Chemicals

- Synthetic Rubber

- Yogurt

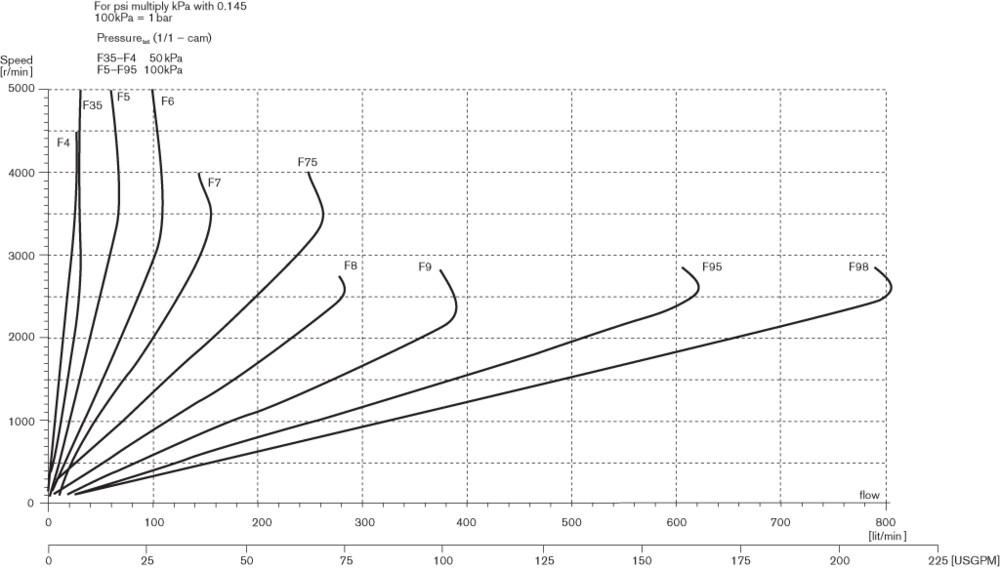

Pump Sizes F35 - F95

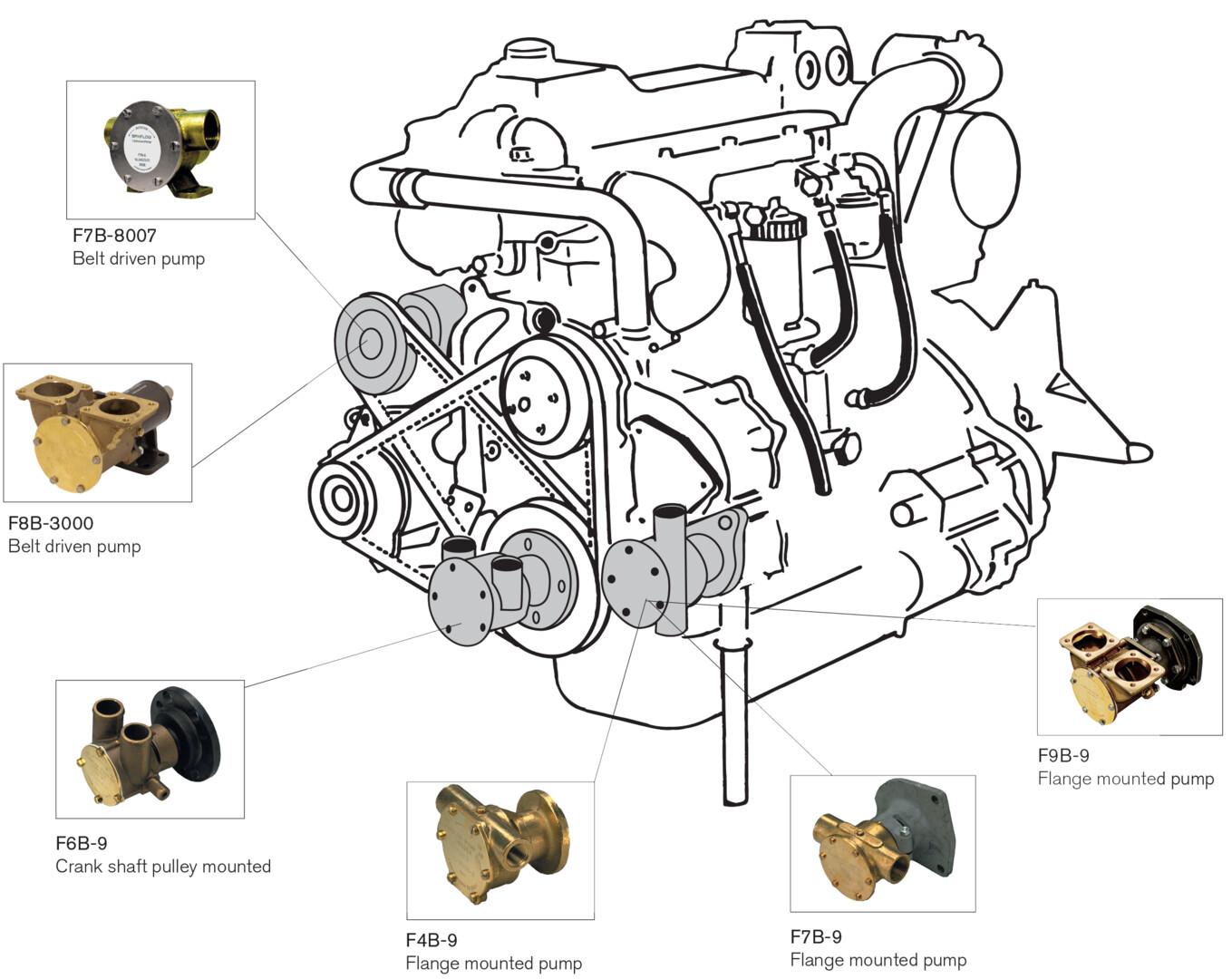

SPX FLOW Johnson Pump Marine is one of the leading original equipment pump suppliers to the largest manufacturers world-wide of inboard engines. Engine cooling pumps, the F-series, are available in several different styles and sizes to satisfy different cooling system needs. Flanged pumps which mount directly to the engine and crank shaft pulley mounted pumps are available for a wide variety of engines. Both flange mounted and pulley driven pedestal pumps can be used to provide cooling with a maximum of ease and flexibility.

FEATURES

- Limited 3 Year Warranty

- Self-priming, a dry pump can lift water up to as much as 3 meters. Thus a flexible impeller pump being used for engine cooling does not need to be located below the water line or manually primed.

- Flexible impeller pumps can pass fairly large solids without clogging or damaging the pump. This reduces the need for filtering the incoming fluid.

- For general raw or fresh water applications, the standard long-lasting neoprene rubber impeller is used. All flexible impeller pumps is that they cannot be permitted to run dry for more than 30 seconds. Both the impeller and the seals depend upon the water for lubrication and will soon fail if run dry.

- Wear parts are easily replaceable

- Service kits are available for all standard models.

- Flange Mounted Pumps (F4B-9, F7B-9, F9B-9)

- Crank Shaft Pulley Mounted Pumps (F6B-9)

- Belt/Pulley Driven Pedestal Pumps (F7B-8, F8B-3000)

- Pump ports available from 3/8" to 2 1/2"

- Capacity up to 625 liters/min (9900 gal/hr)

See this product in the Johnson Pump Marine Catalog: US ‖ GB ‖ DE ‖ ES ‖ FI ‖ SV

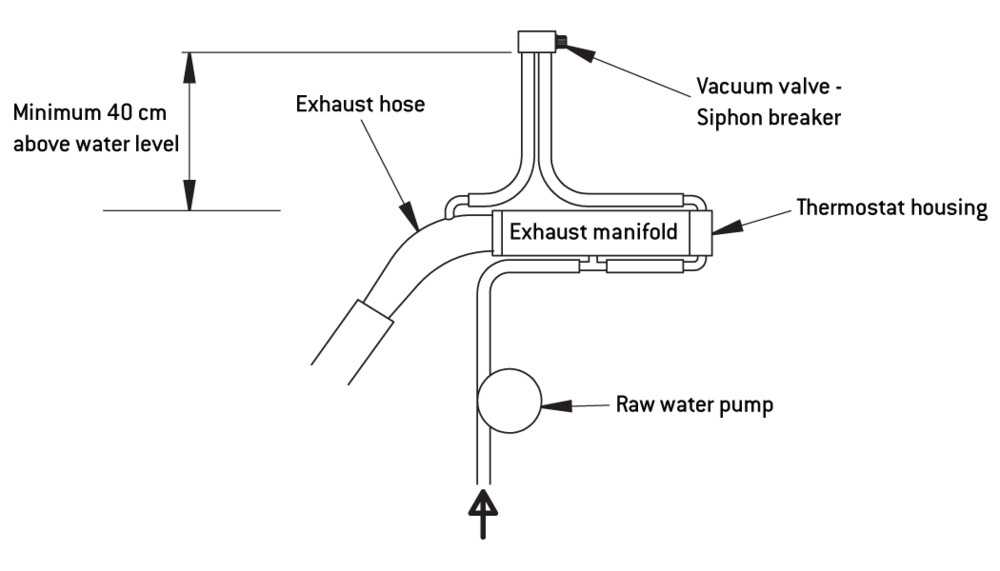

Engine Cooling – Raw Water Handling

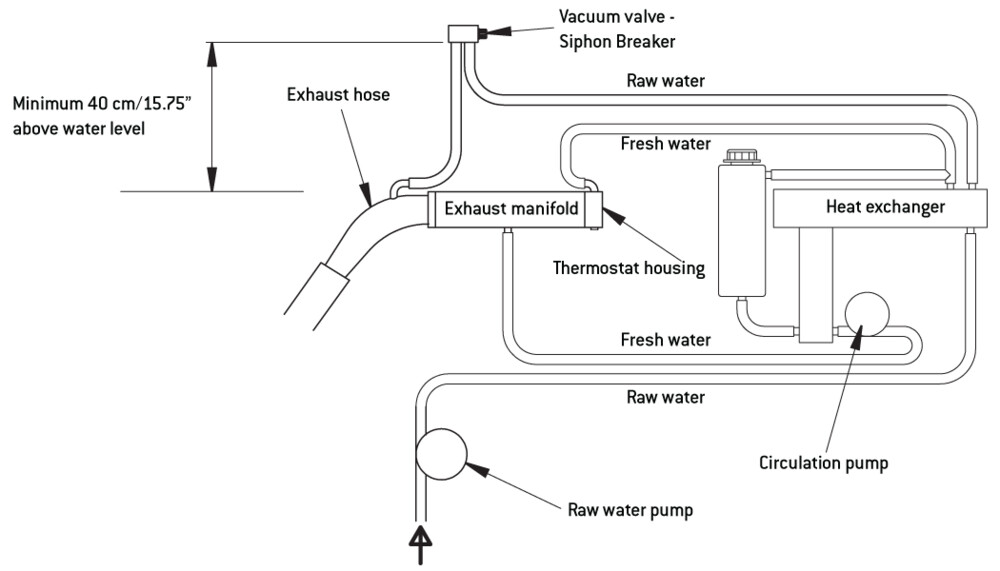

Different Types of Cooling Systems

Fresh Water Handling

For circulation of the internal, closed, fresh water circuit of the cooling system SPX FLOW Johnson Pump can

offer a number of alternatives in its DC driven Circulation Pump series (see Circulation Pumps page).

It is also common to use a flexible impeller pump for this purpose if it is located on the cold side of the system

(max. 55°C/ 131°F ). Other types of belt-driven centrifugal pumps may also be useful. The closed circuit normally transfers heat from the engine to the heat exchanger. The liquid is a water and anti-freeze mixture.

Product Specifications

COOLING CAPACITY

The required output of the cooling pump – raw water as well as fresh water handling – is related to:

- Engine size and type (gasoline or diesel)

- Type of cooling system (size of heat exchanger)

- Water cooled engine oil, reverse gear, exhaust system

Contact your local dealer for more information, or for indirect cooling systems your supplier of heat exchangers.

Raw Water Cooled Engines

Fresh Water Cooled Engines

Capacity Range

(based on water at 20˚C/68˚F)

Bronze Impeller Pump Performance Tables

Note! Reduced cam - 30-40% lower capacity

Impeller of nitrile - adjust total head approx. 30% down

| F35B | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2000 rpm | 2500 rpm | ||||||||||||||

| Bar | kPa | ft | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM |

| 0.3 | 30 | 10.1 | 0.06 | 5.2 | 1.4 | 0.09 | 6.8 | 1.8 | 0.13 | 11.2 | 3.0 | 0.16 | 14.0 | 3.7 | 0.18 | 16.0 | 4.2 | 0.18 | 20.5 | 5.4 |

| 0.6 | 60 | 20.1 | 0.09 | 4.6 | 1.2 | 0.09 | 6.2 | 1.6 | 0.13 | 10.6 | 2.8 | 0.16 | 13.7 | 3.6 | 0.18 | 15.8 | 4.1 | 0.18 | 19.6 | 5.2 |

| 1.0 | 100 | 33.5 | 0.09 | 4.0 | 1.1 | 0.09 | 5.6 | 1.5 | 0.18 | 9.2 | 2.4 | 0.18 | 11.8 | 3.1 | 0.18 | 13.6 | 3.6 | 0.18 | 17.0 | 4.5 |

| F4B | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2000 rpm | 2500 rpm | ||||||||||||||

| Bar | kPa | ft | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM |

| 0.3 | 30 | 10.1 | 0.06 | 12.0 | 3.2 | 0.09 | 15.0 | 4.0 | 0.13 | 23.0 | 6.0 | 0.17 | 27.0 | 7.1 | 0.18 | 30.5 | 8.1 | 0.18 | 34.5 | 9.1 |

| 0.6 | 60 | 20.1 | 0.09 | 11.0 | 2.9 | 0.09 | 14.0 | 3.7 | 0.13 | 21.0 | 5.4 | 0.17 | 25.0 | 6.6 | 0.18 | 28.0 | 7.4 | 0.18 | 33.0 | 8.7 |

| 1.0 | 100 | 33.5 | 0.09 | 9.0 | 2.4 | 0.09 | 11.0 | 2.9 | 0.18 | 18.0 | 4.8 | 0.18 | 22.0 | 5.8 | 0.18 | 25.0 | 6.6 | 0.18 | 29.5 | 7.8 |

| 1.5 | 150 | 50.3 | 0.09 | 4.5 | 1.2 | 0.09 | 7.0 | 1.8 | 0.18 | 13.5 | 3.6 | 0.18 | 17.0 | 4.5 | 0.18 | 20.0 | 5.3 | 0.2 | 25.0 | 6.6 |

| F5B | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2000 rpm | ||||||||||||

| Bar | kPa | ft | kW | l/min | GPM | kW | l/min | GPM | kW | l/min | GPM | kW | l/min | GPM | kW | l/min | GPM |

| 0.3 | 30 | 10.1 | 0.13 | 16.0 | 4.2 | 0.18 | 21.0 | 5.5 | 0.37 | 33.0 | 8.7 | 0.37 | 41.0 | 10.8 | 0.37 | 46.0 | 12.2 |

| 0.6 | 60 | 20.1 | 0.13 | 15.0 | 4.0 | 0.18 | 20.0 | 5.3 | 0.37 | 32.0 | 8.5 | 0.37 | 39.5 | 10.4 | 0.37 | 45.0 | 11.9 |

| 1.0 | 100 | 33.5 | 0.13 | 14.0 | 3.7 | 0.18 | 19.0 | 5.0 | 0.37 | 30.0 | 7.9 | 0.37 | 37.0 | 9.8 | 0.37 | 42.0 | 11.1 |

| 1.5 | 150 | 50.3 | 0.13 | 13.0 | 3.4 | 0.18 | 17.0 | 4.5 | 0.37 | 27.0 | 7.1 | 0.37 | 33.5 | 8.9 | 0.37 | 38.0 | 10.0 |

| 2.0 | 200 | 67.1 | - | - | - | - | - | - | 0.37 | 22.0 | 5.8 | 0.37 | 28.5 | 7.5 | 0.37 | 33.0 | 8.07 |

| F7B | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2000 rpm | ||||||||||||

| Bar | kPa | ft | kW | l/min | GPM | kW | l/min | GPM | kW | l/min | GPM | kW | l/min | GPM | kW | l/min | GPM |

| 0.3 | 30 | 10.1 | 0.37 | 36.0 | 9.5 | 0.37 | 46.0 | 12.2 | 0.75 | 74.0 | 19.6 | 0.75 | 98.0 | 25.9 | 0.75 | 107.0 | 28.3 |

| 0.6 | 60 | 20.1 | 0.37 | 34.0 | 9.0 | 0.37 | 44.0 | 11.6 | 0.75 | 72.0 | 19.0 | 0.75 | 96.0 | 25.4 | 0.75 | 104.0 | 27.5 |

| 1.0 | 100 | 33.5 | 0.37 | 29.0 | 7.7 | 0.37 | 40.0 | 10.6 | 0.75 | 67.0 | 17.7 | 0.75 | 87.0 | 23.0 | 0.75 | 98.0 | 25.9 |

| 1.8 | 180 | 60.4 | 0.37 | 21.0 | 5.5 | 0.37 | 30.0 | 7.9 | 0.75 | 57.0 | 15.1 | 0.75 | 73.0 | 19.3 | 0.75 | 84.0 | 22.2 |

| 2.5 | 250 | 83.8 | - | - | - | - | - | - | 0.75 | 37.0 | 9.8 | 1.1 | 52.0 | 13.7 | 1.1 | 63.0 | 16.6 |

| F8B | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2000 rpm | ||||||||||||

| Bar | kPa | ft | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM |

| 0.3 | 30 | 10.1 | 0.37 | 87.0 | 23.0 | 0.75 | 114.0 | 30.1 | 1.1 | 188.0 | 50.0 | 1.5 | 241.0 | 63.7 | 1.5 | 279.0 | 73.7 |

| 0.6 | 60 | 20.1 | 0.37 | 80.0 | 21.1 | 0.75 | 107.0 | 28.3 | 1.1 | 180.0 | 47.6 | 1.5 | 233.0 | 61.6 | 1.5 | 270.0 | 71.3 |

| 1.0 | 100 | 33.5 | 0.37 | 73.0 | 19.3 | 0.75 | 101.0 | 26.7 | 1.1 | 177.0 | 46.8 | 1.5 | 228.0 | 60.2 | 1.5 | 264.0 | 69.7 |

| 1.8 | 180 | 60.4 | - | - | - | 1.1 | 70.0 | 18.5 | 1.1 | 148.0 | 39.1 | 2.2 | 203.0 | 53.6 | 2.2 | 242.0 | 63.4 |

| 2.5 | 250 | 83.8 | - | - | - | - | - | - | 1.1 | 108.0 | 28.5 | 2.2 | 166.0 | 43.9 | 2.2 | 208.0 | 55.0 |

| F9B-5000 | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2000 rpm | ||||||||||||

| Bar | kPa | ft | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM |

| 0.3 | 30 | 10.1 | 0.75 | 129.0 | 34.1 | 0.75 | 170.0 | 44.9 | 1.5 | 268.0 | 70.8 | 1.5 | 331.0 | 87.5 | 2.2 | 388.8 | 102.7 |

| 0.6 | 60 | 20.1 | 0.75 | 124.0 | 32.8 | 0.75 | 161.0 | 42.5 | 1.5 | 260.0 | 68.9 | 2.2 | 323.0 | 85.3 | 2.2 | 383.1 | 101.2 |

| 1.0 | 100 | 33.5 | 0.75 | 118.8 | 31.4 | 1.1 | 156.0 | 41.2 | 1.5 | 255.6 | 67.5 | 2.2 | 315.2 | 83.3 | 3.0 | 379.2 | 100.2 |

| 1.8 | 180 | 60.4 | 1.1 | 105.0 | 27.7 | 1.1 | 140.0 | 37.0 | 1.5 | 235.0 | 62.1 | 2.2 | 286.1 | 75.6 | 3.0 | 351.3 | 92.8 |

| 2.5 | 250 | 83.8 | 1.1 | 83.7 | 22.1 | 1.5 | 102.0 | 26.9 | 2.2 | 208.0 | 55.2 | 3.0 | 266.0 | 70.3 | 3.0 | 304.1 | 80.3 |

| F9B-5600 | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2000 rpm | ||||||||||||

| Bar | kPa | ft | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM |

| 0.3 | 30 | 10.1 | 0.75 | 129.0 | 34.1 | 1.1 | 170.0 | 44.9 | 1.5 | 270.0 | 71.3 | 1.5 | 331.0 | 87.5 | 2.2 | 376.0 | 99.3 |

| 0.6 | 60 | 20.1 | 0.75 | 126.0 | 32.8 | 1.1 | 165.0 | 43.6 | 1.5 | 266.0 | 70.3 | 2.2 | 323.0 | 85.3 | 2.2 | 368.0 | 97.2 |

| 1.0 | 100 | 33.5 | 0.75 | 123.0 | 32.5 | 1.1 | 161.1 | 42.6 | 2.2 | 260.0 | 68.7 | 2.2 | 314.0 | 83.3 | 3.0 | 361.0 | 95.4 |

| 1.8 | 180 | 60.4 | 0.75 | 110.0 | 29.1 | 1.5 | 153.0 | 40.4 | 2.2 | 242.0 | 63.9 | 2.2 | 291.0 | 76.9 | 3.0 | 340.0 | 89.8 |

| 2.5 | 250 | 83.8 | 1.1 | 90.0 | 23.8 | 1.5 | 130.0 | 34.3 | 2.2 | 218.0 | 57.6 | 3.0 | 269.0 | 71.1 | 3.0 | 312.0 | 82.4 |

| 3.0 | 300 | 100.6 | 1.5 | 61.0 | 16.1 | 2.2 | 102.0 | 26.9 | 3.0 | 190.0 | 50.2 | 3.0 | 242.0 | 63.9 | 3.5 | 284.0 | 75.0 |

| 3.5 | 350 | 117.4 | - | - | - | - | - | - | 3.0 | 160.0 | 42.3 | 3.5 | 205.0 | 54.2 | 3.5 | 235.0 | 62.1 |

| F95B | 700 rpm | 900 rpm | 1400 rpm | 1750 rpm | 2500 rpm | ||||||||||||

| Bar | kPa | ft | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM | kW | L/min | GPM |

| 0.5 | 50 | 16.8 | 0.75 | 182.6 | 48.2 | 1.1 | 236.5 | 62.5 | 1.5 | 384.2 | 101.5 | 2.2 | 483.6 | 127.8 | 4.0 | 626.7 | 165.5 |

| 1.0 | 100 | 33.5 | 1.1 | 172.7 | 45.6 | 1.1 | 231.3 | 61.1 | 1.5 | 372.0 | 98.3 | 3.0 | 472.9 | 124.9 | 5.5 | 617.9 | 163.2 |

| 1.5 | 150 | 50.3 | 1.1 | 160.1 | 42.3 | 1.5 | 214.5 | 56.7 | 2.2 | 350.4 | 92.6 | 3.0 | 444.1 | 117.3 | 5.5 | 583.8 | 154.2 |

| 2.0 | 200 | 67.1 | 1.1 | 132.3 | 35.0 | 1.5 | 181.0 | 47.8 | 3.0 | 315.4 | 83.3 | 3.5 | 406.2 | 107.3 | 5.5 | 553.1 | 146.1 |

| 2.5 | 250 | 83.8 | 1.5 | 79.5 | 21.0 | 2.2 | 137.8 | 36.4 | 3.0 | 267.6 | 70.7 | 4.0 | 361.3 | 95.5 | 7.5 | 506.4 | 133.8 |