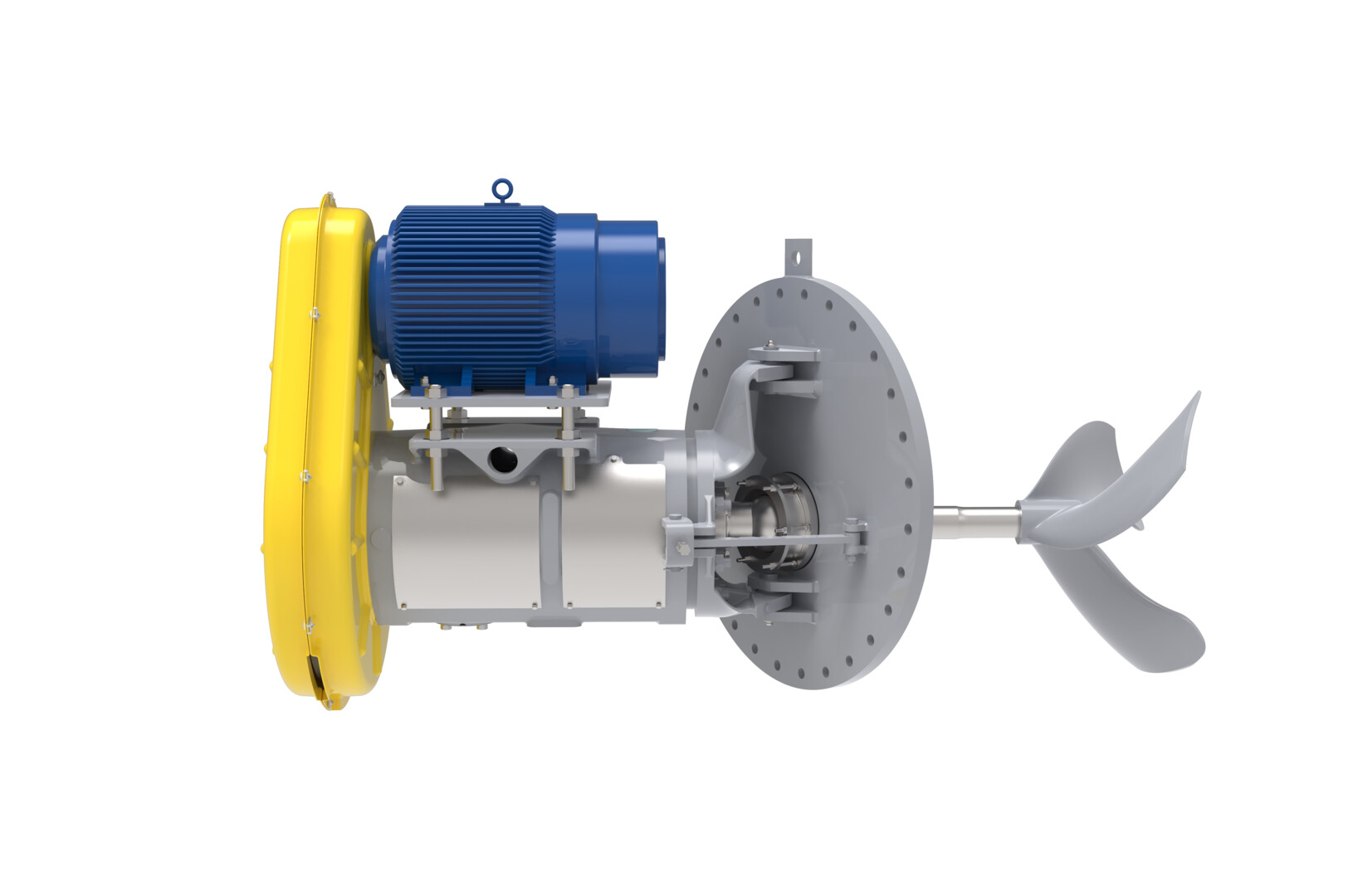

Side Entry Mixing System

Our BSER side entry mixer drive combines with our Forward Rake Advanced Pitch Propeller that creates a collimated flow for optimal BS&W (bottom, sediment and water) control, faster blending and energy efficiency.