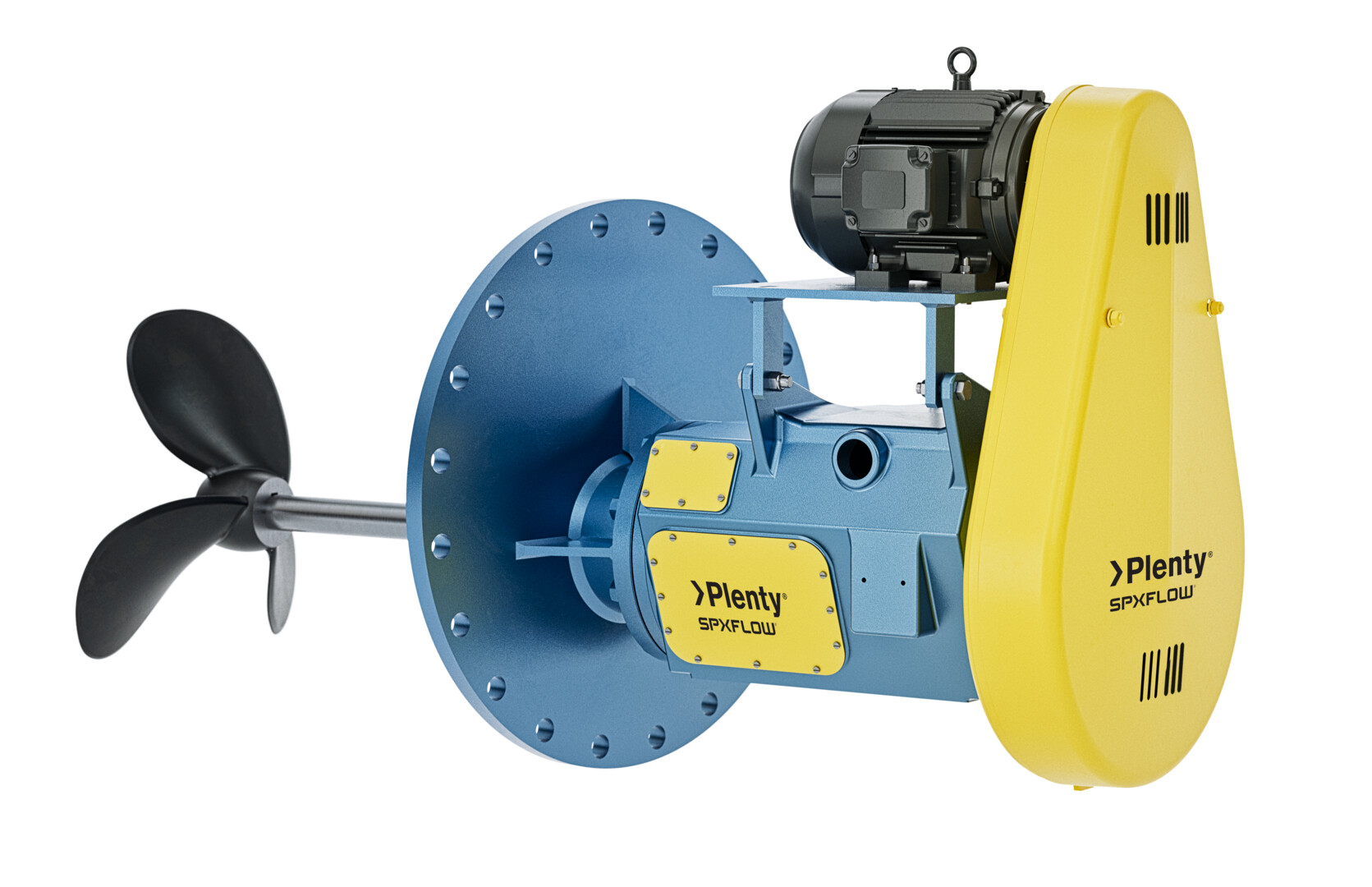

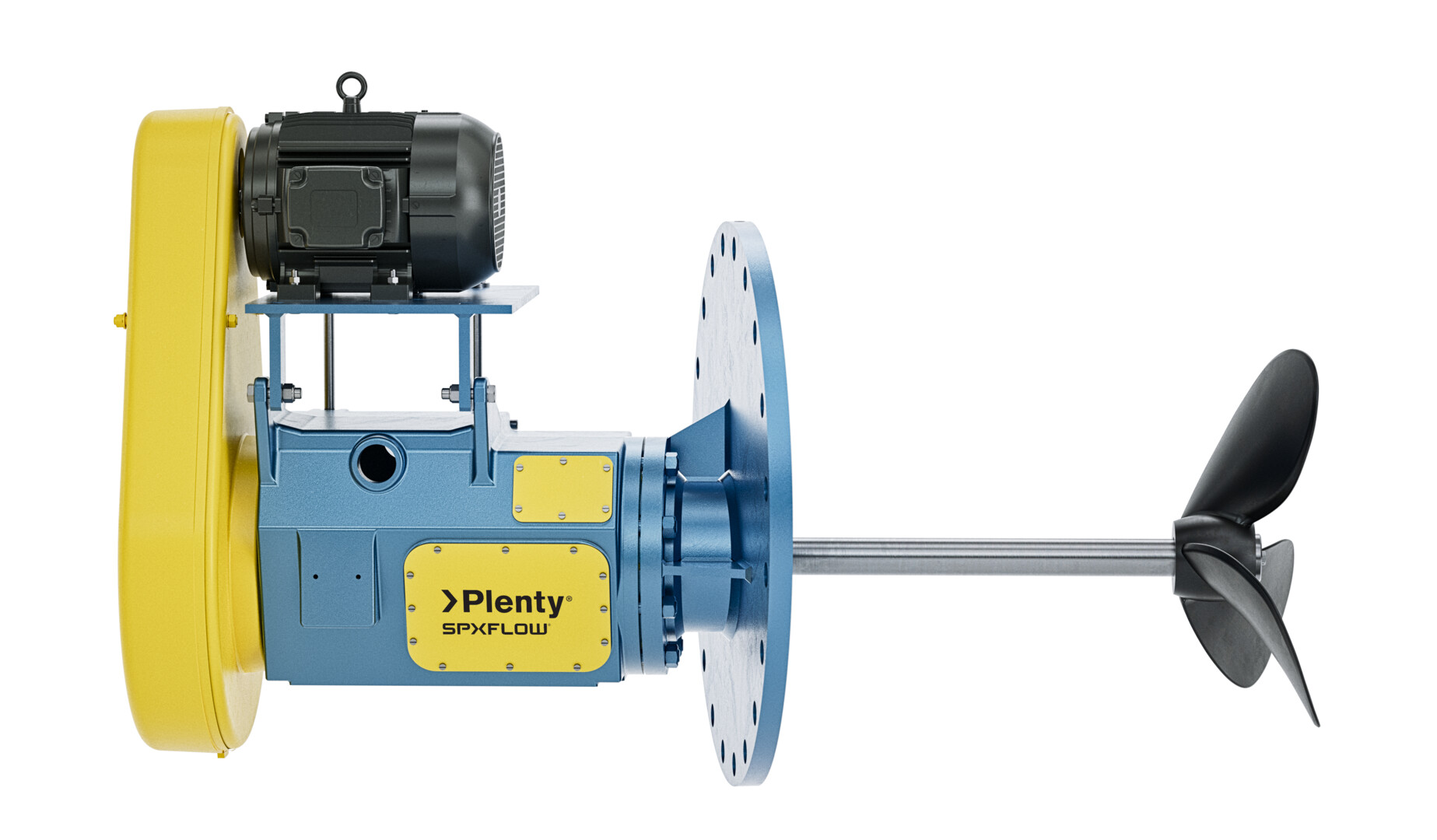

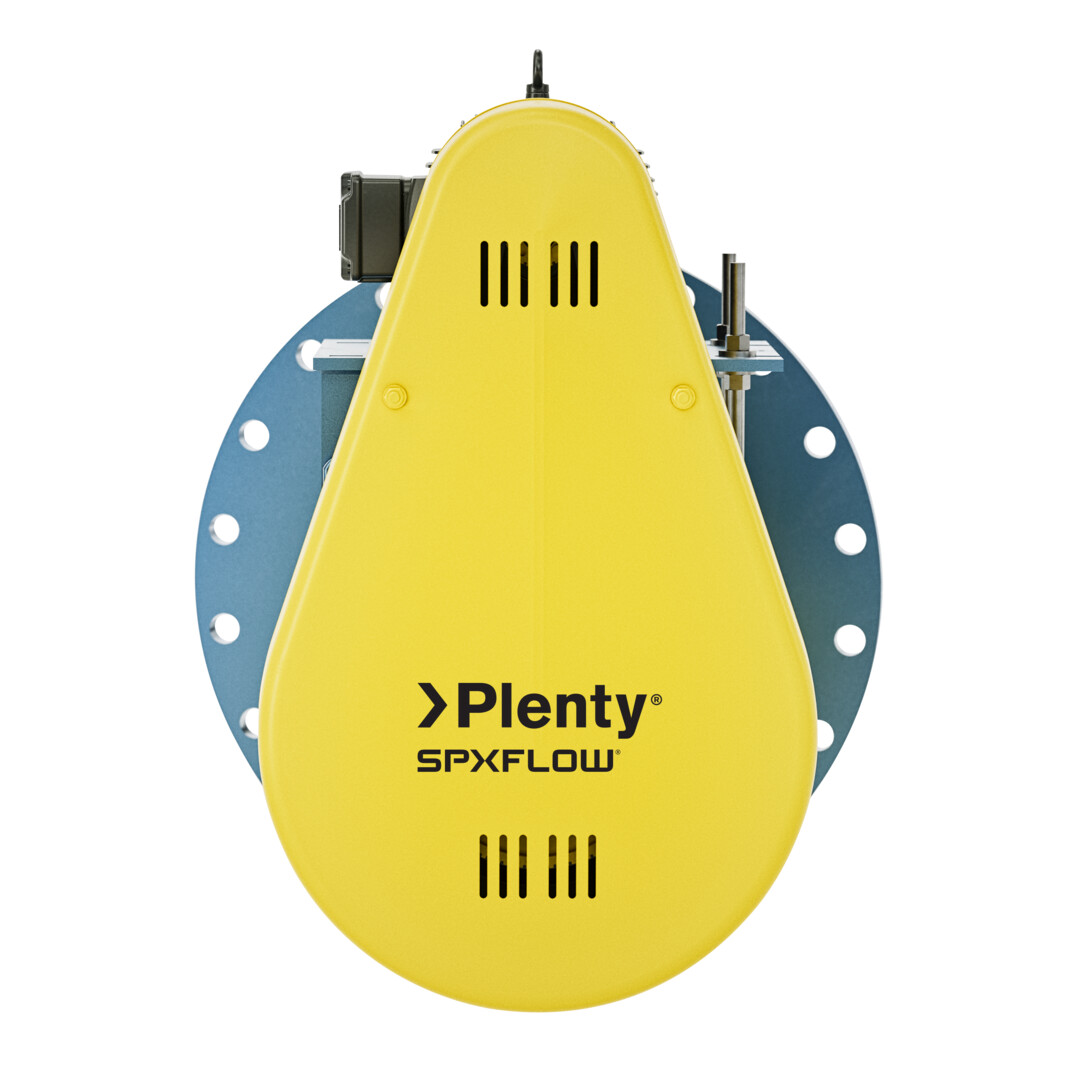

TM & STM Series Belt Drive Heavy-Duty Side-Entry Mixers

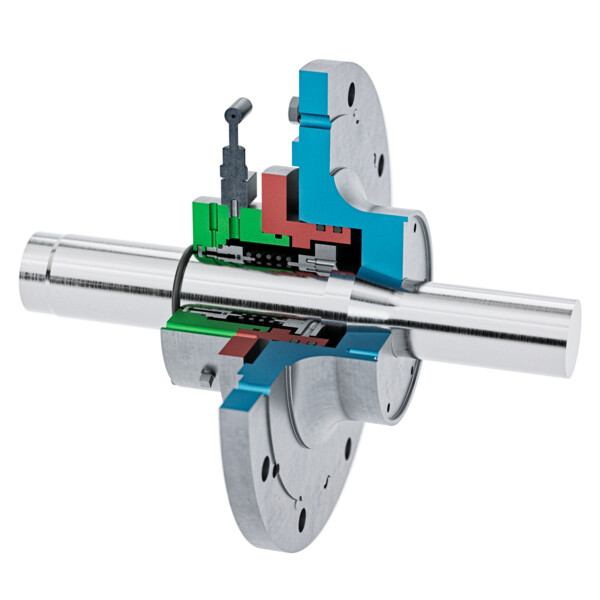

Discover the TM & STM Series Belt Drive Mixers, designed for high-efficiency mixing in industrial applications. Featuring advanced helical impellers, robust belt drive systems, and optional swivel angle configurations, these mixers deliver superior performance for crude oil storage, biofuels, wastewater, and more. Ensure top-to-bottom blending, sediment suspension, and temperature uniformity with Plenty's innovative side-entry mixers. Explore our customizable options and dimensions tailored to your tank needs.