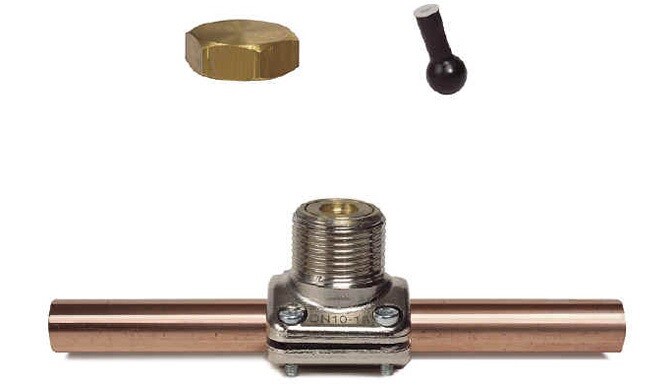

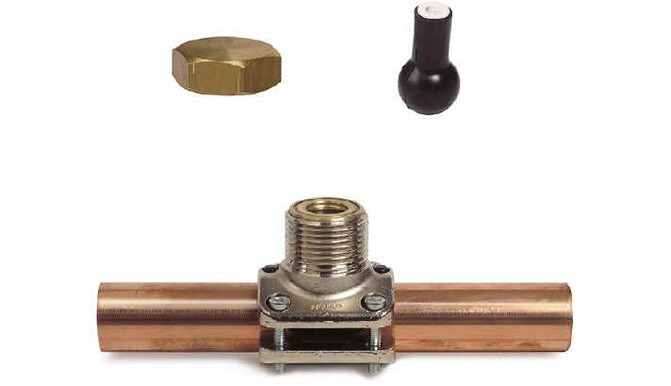

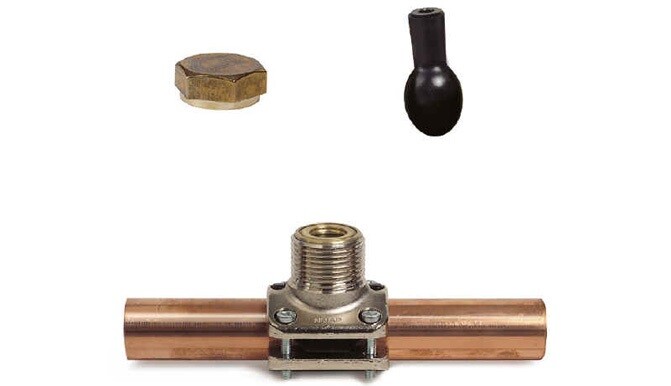

NoTap® Pipe Blocking

NoTap® pipe blocking is a complete system for easily and economically repairing pipes and installing or replacing equipment in your pipe system, without having to drain the system first. Sections of pipe to be worked on can quickly be temporarily isolated by means of internally blocking the pipes with inflated balloons.

The NoTap method can be used for hot water, fresh (tap) water, compressed air and refrigerants (glycol and salt based solutions). It is suitable for all pipes of metal, for example: black steel, painted steel, galvanized steel, stainless steal as well as copper. Valid for both thin-walled and annealed tempered pipe.

Blockings can be carried out on pipes up to DN50 (2") and connections up to DN300 (12").