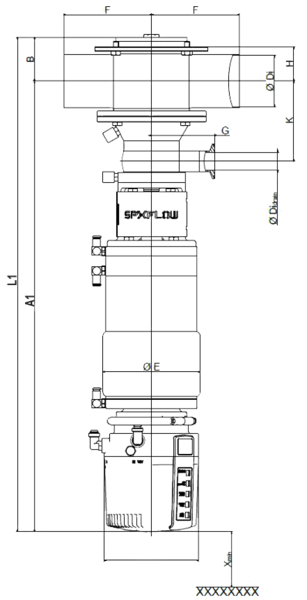

DT4 Series - Tank Outlet Double Seat Mixproof Valves

The DT4 tank outlet mixproof valve is used for the reliable separation between the tank and servicing pipeline. The DT4 tank outlet is an extension to the D4 Series mixproof family which helps fulfil today’s customer demands for production flexibility, increased productivity, rapid return on investment (ROI) and improved product quality in the food and drink, dairy, personal care and brewing process industries.