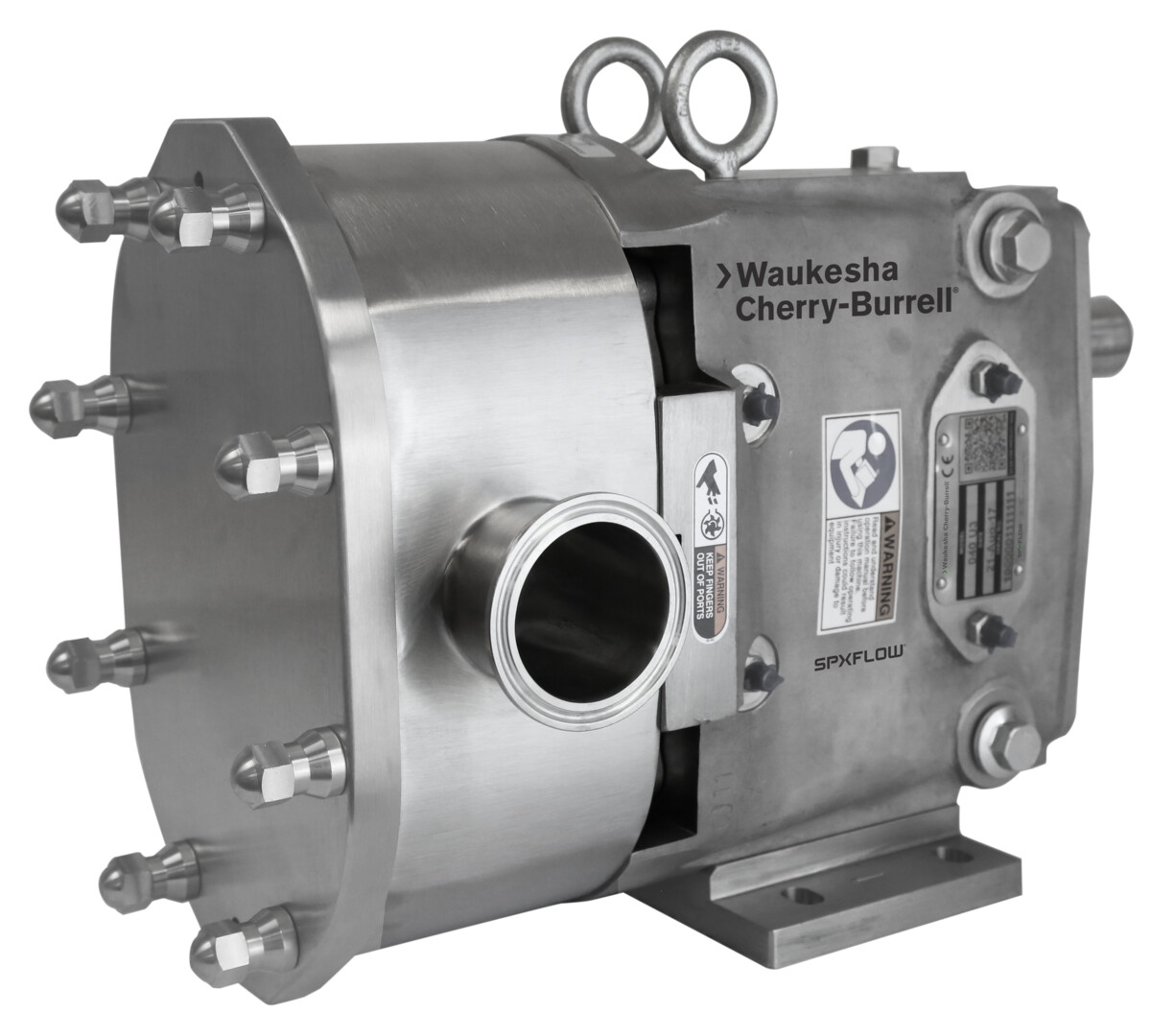

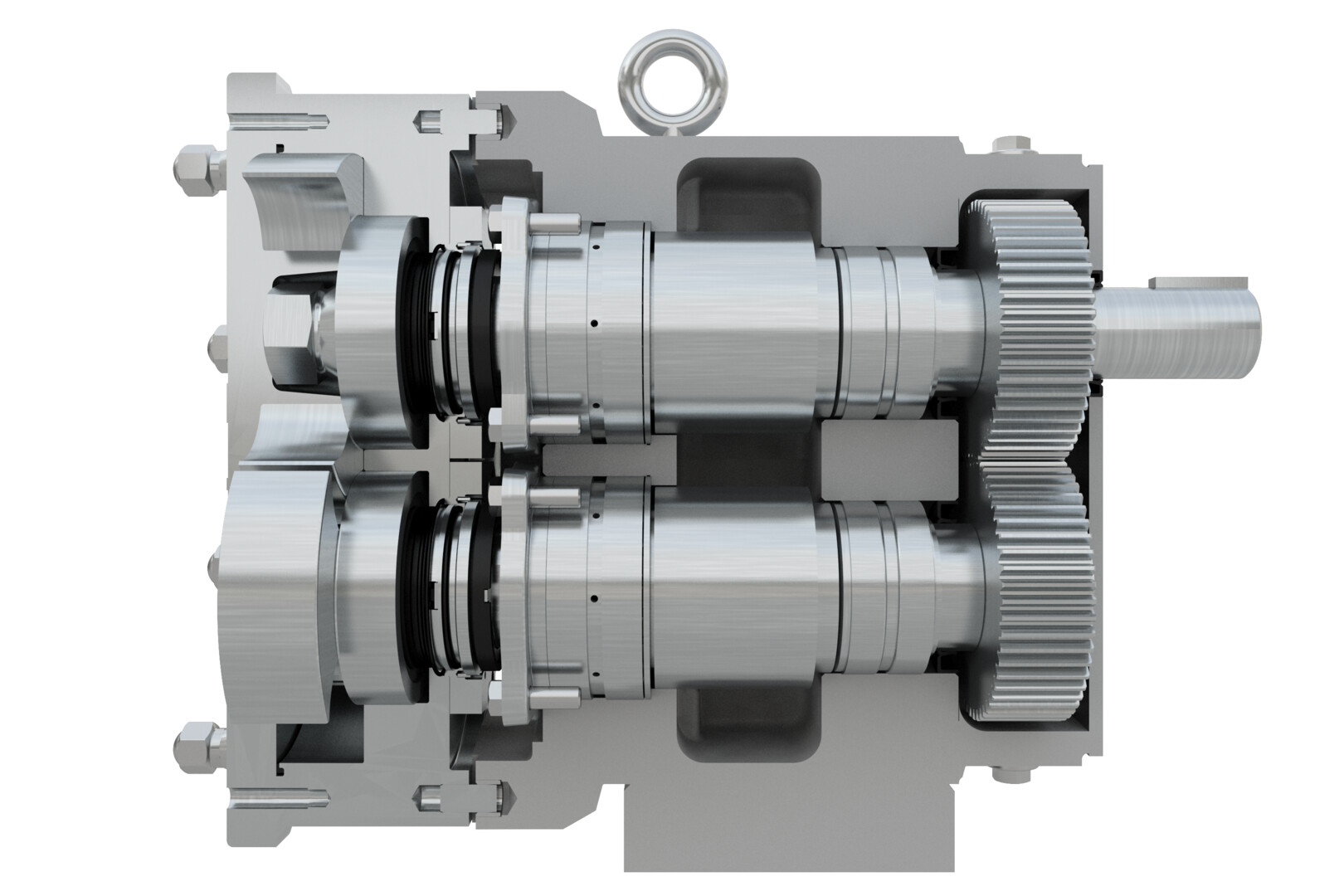

Universal 3 Series - Positive Displacement Pumps

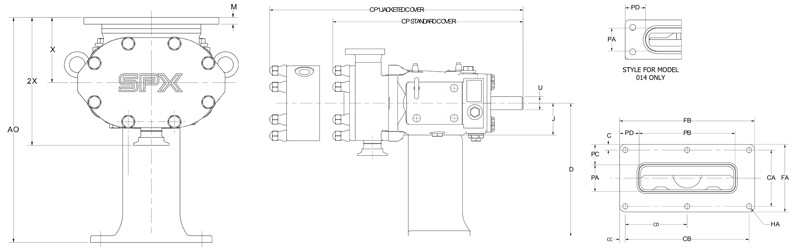

Universal 3 Series positive displacement pumps are engineered to perform in food & beverage, dairy, pharmaceutical, personal care, chemical and industrial industries. The Universal 3 series includes a standard stainless steel gear case, the choice of multiple seal options, and bearings that are sealed from the product zone. Many options are available for the Universal 3 series pump including an aseptic configuration with aseptic ports and cover.

Quick Ship

Ships from order date in 10 days or less.

FEATURES

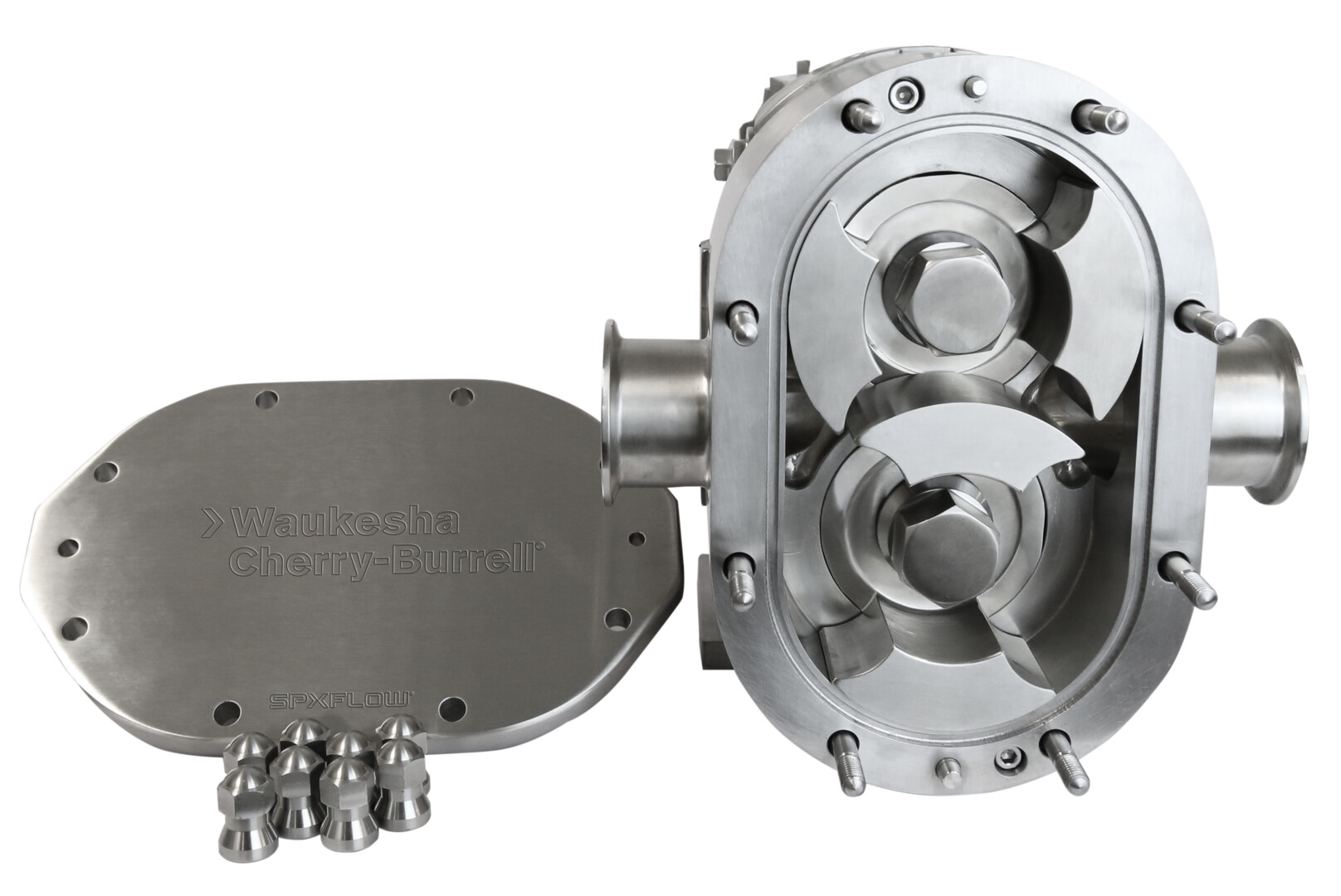

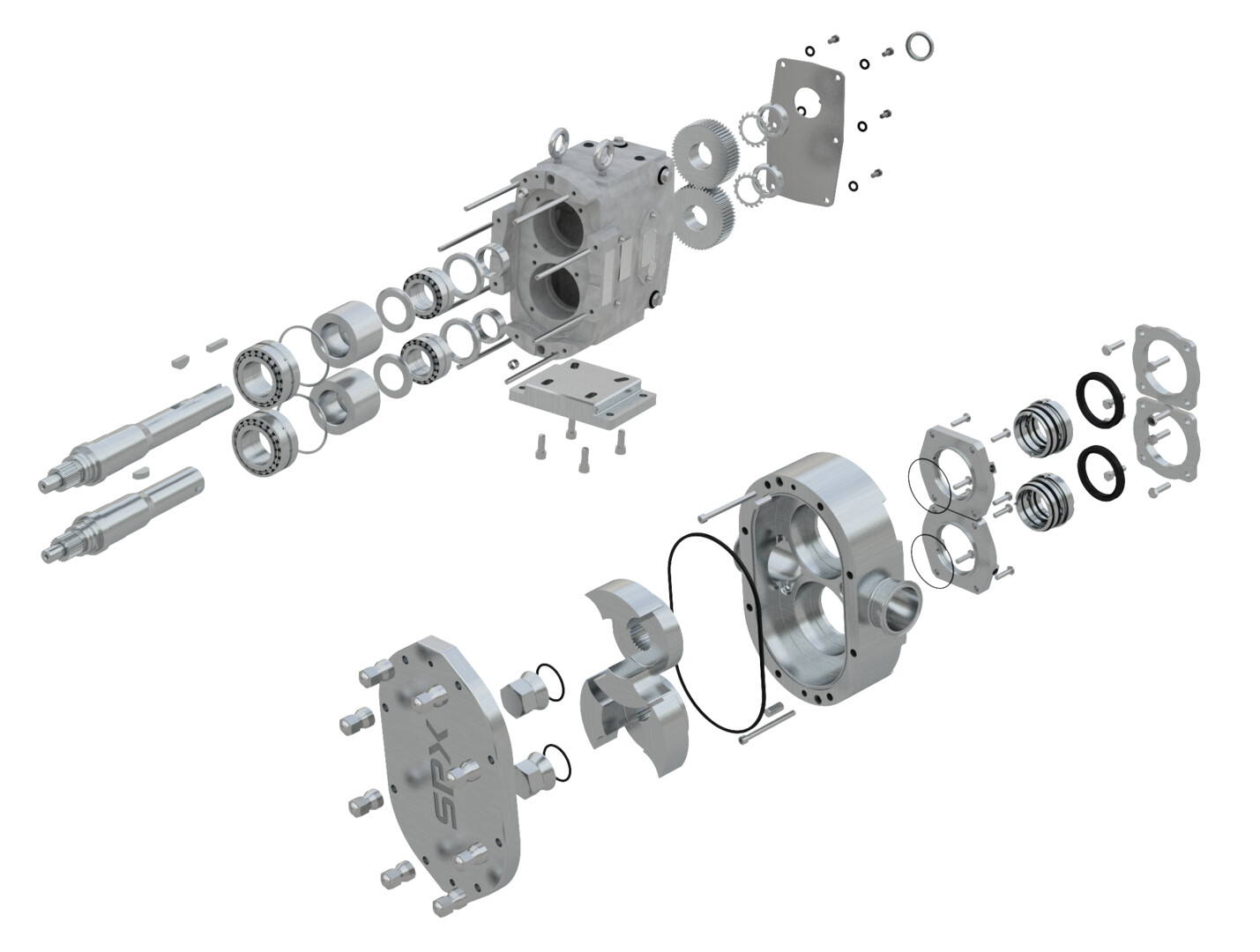

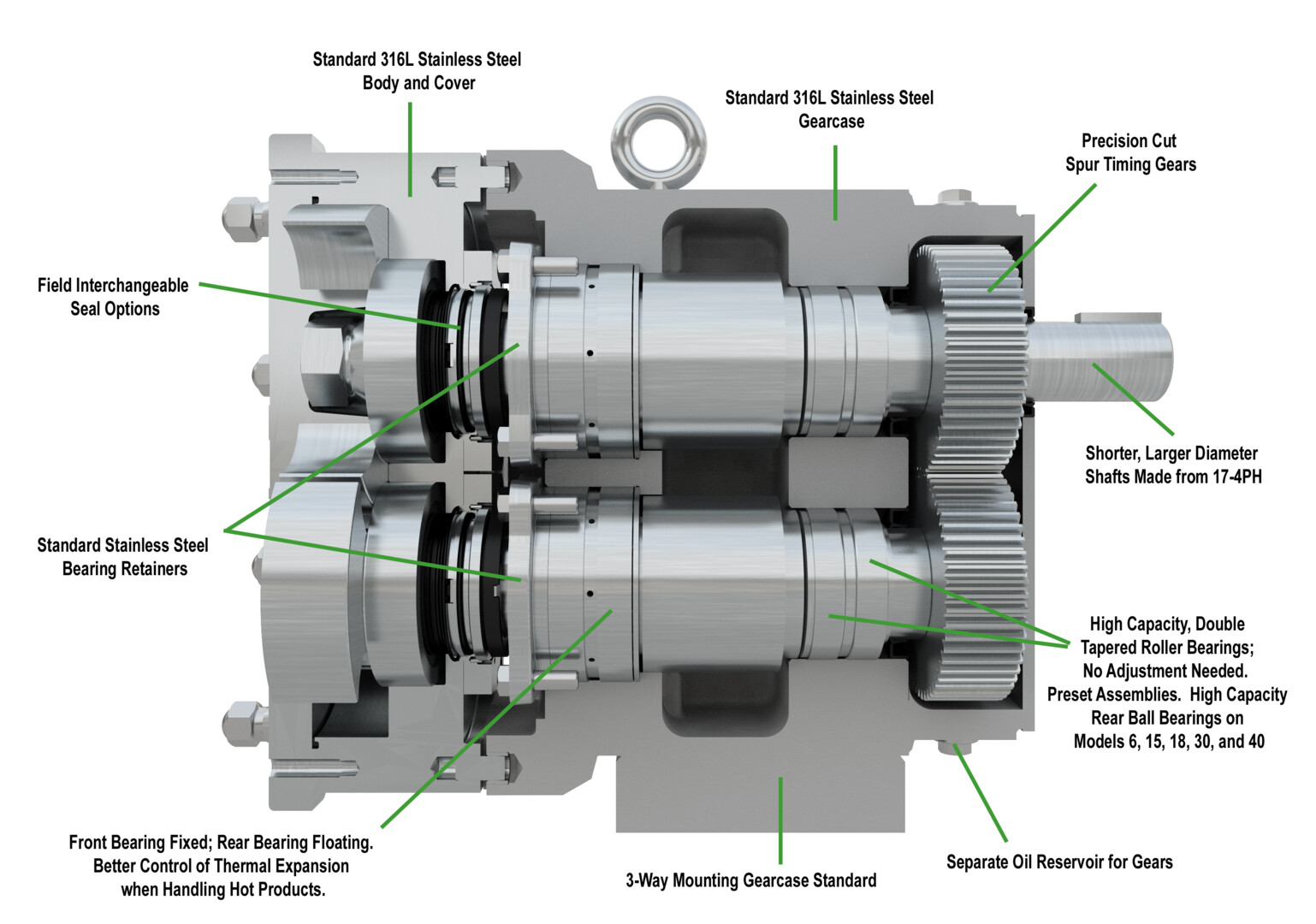

The Universal 3 Series is the latest addition to the Waukesha positive displacement pump family by SPX FLOW. It offers a front loading seal design with no bearings in the product zone. Operating pressure capacities up to 500 psi (34.5 bar) and standard 316L stainless steel body and cover makes this an attractive hygienic pump option for your most challenging applications in the food and beverage industry. Assembled and tested in Delavan, WI with "Waukesha 88" non-galling rotors and a standard 304 stainless steel gear case provides an ideal fluid transfer solution that is able to withstand the rigors of daily processing environments. Long-life Features

- Up to 500 psi (34.5 bar) pressure capability

- Pumps rated to 300°F (149°C) as standard

- Special rotor nut designed for extended service without loosening

- No bearings in the product zone

- New shafts are shorter and have larger diameter 17-4 PH shafts:

- Reduces overhung load which improves shaft alignment and decreases seal and bearing wear for extended seal life.

- Improves shaft strength and stiffness helping to eliminate vibration

- Heavy duty stainless steel bearing frame standard

- Double tapered roller bearings

- Greased lubed bearings for positive lubrication to all bearings over entire speed, temperature and pressure range

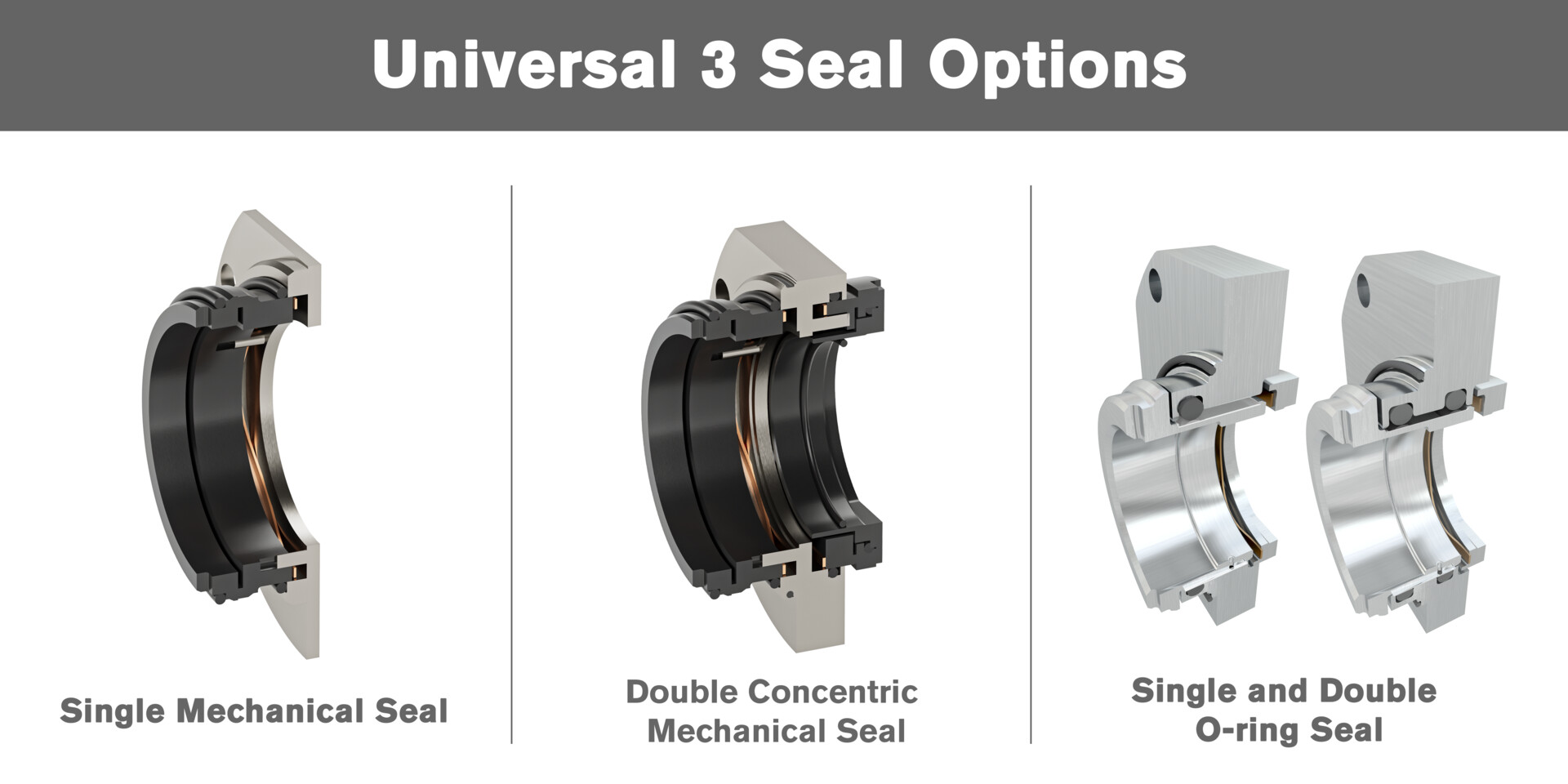

- Body retaining screws for maintaining mechanical seal contact during inspection

- Extended outer seal life. A wave spring, instead of an O-ring, mechanically loads the seal

- Unique mechanical seal design utilizes 2 pin stationary seal and special design shaft for rotary seal

- Pumps for Life™ Lifecycle Program

- Buy a new U3 Pump

- Maintain with Genuine SPX FLOW Parts

- Trade in Old pump for New pump at a remanufactured price