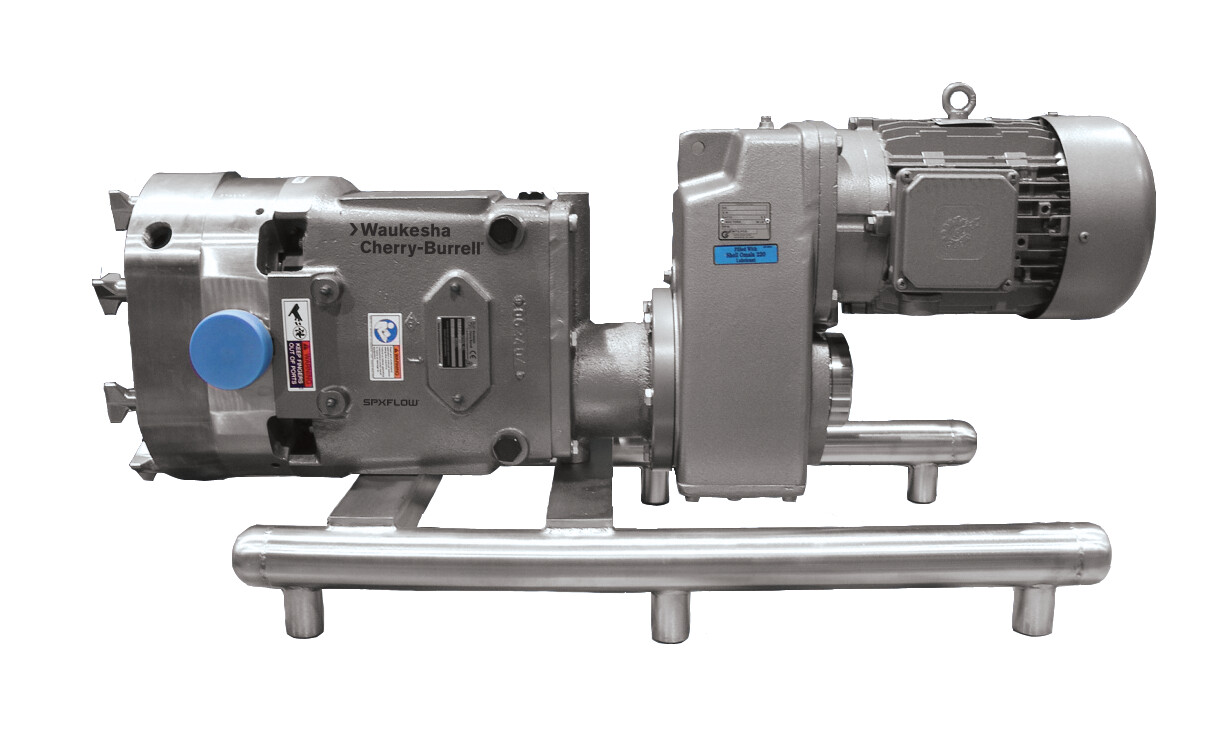

Universal Series - Tru-Fit® - Positive Displacement Pumps

Product Type(s) : Positive Displacement Pumps

Description :

WHERE TO BUY

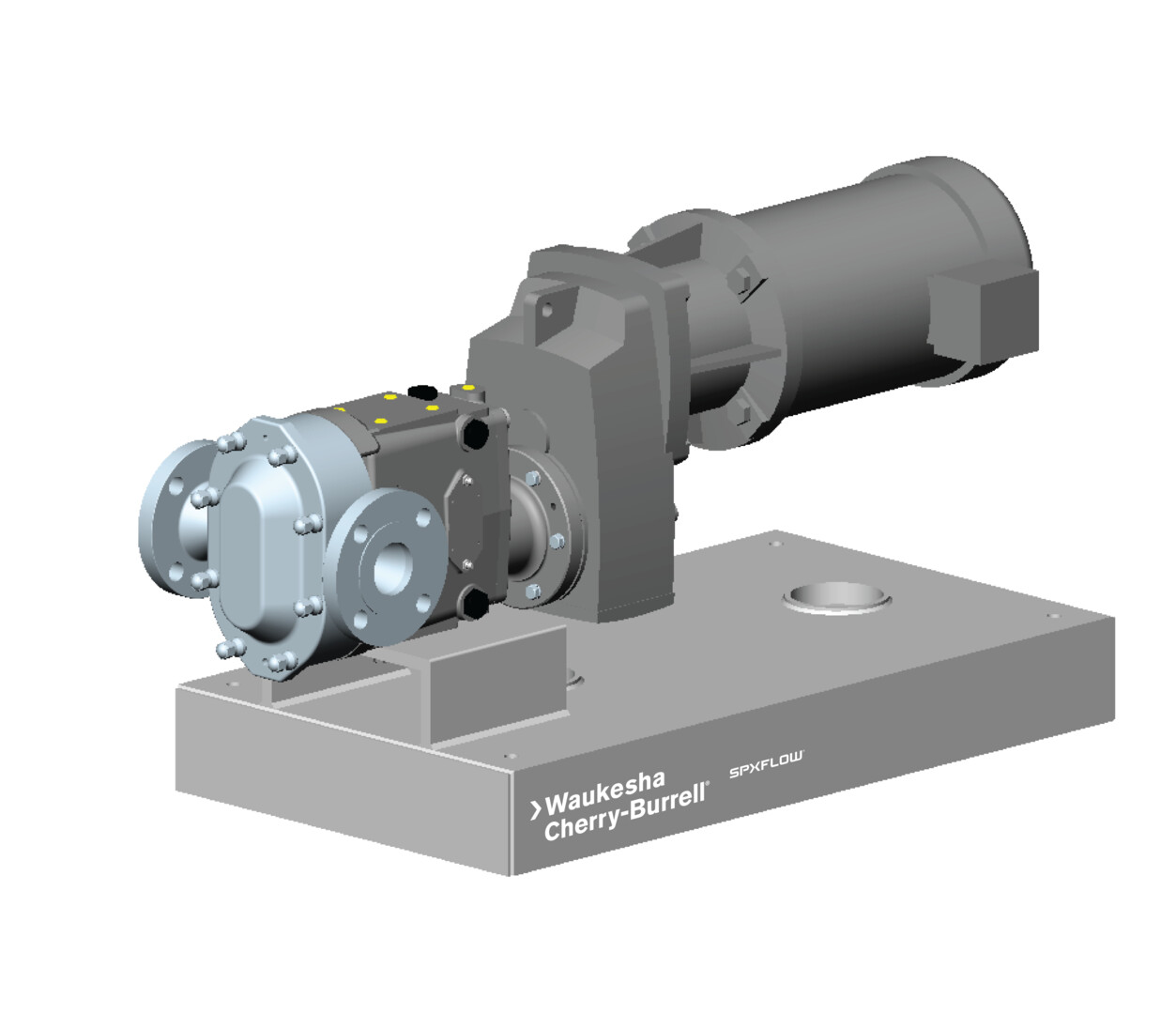

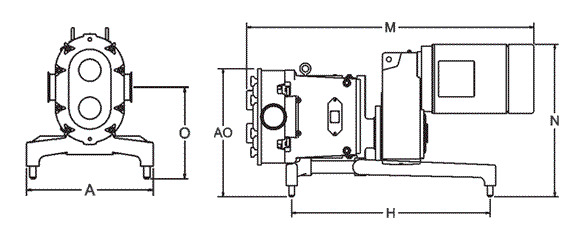

Tru-Fit models are available for U1, U2, U3, Lobe, Twin Screw (UTS) and 5000 positive displacement pumps. Tru-Fit pump model advantages include: No shaft alignment necessary, no coupling guard required and ease of maintenance.

FEATURES

Benefits:

- No shaft alignment necessary

- No coupling guard required

- Special base design enhances cleanability

- Reduces overall length of complete unit by an average of 20-25%

- Average of 10-20 gear ratios available per horsepower

- NEMA or IEC frames available, right angle reducer also available for additional space savings

- 1/2 through 60 horsepower drive options available

- Horizontal or vertical porting available

- Separate oil sump for gear reducer and timing gears

- Easy to maintain

Applications:

SOLVENTS -

Acetone, Carbon “Tet”, Spirits, M.E.K. Turpentine

OIL & LUBRICANTS -

Crude Oil, Diesel #2 Oil, Bunker Oil, Lubricant Oil, Fuel Oils, Greases, Oil Additives

OTHER -

Acids, Adhesives, Alkalies, Animal Fats, Ammonium Nitrate, Defoamers, Glue, Latex, Lacquer, Melamine, Paper Coatings, Polymers, Polyvinyl Alcohol, Printing Ink, Resins, Silicone Emulsions, Soaps, Sludges, Starches, Urea