Flex-Mix DarMix+

High-Efficiency, Hygienic In-line Mixing Solutions

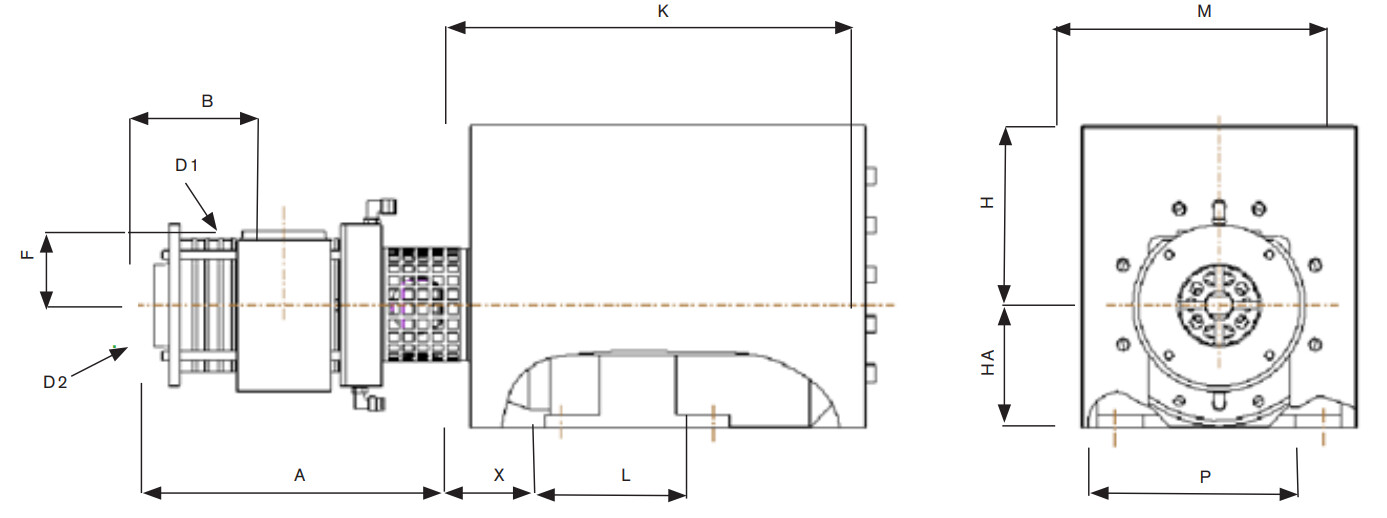

The APV DarMix+ Series from SPX FLOW is a compact, energy-efficient in-line mixer designed for hygienic mixing of butter, butter blends and other food, beverage and dairy products. It ensures consistent results across viscosities, with CIP compatibility and non product-contact bearings to reduce cleaning time, energy use and operating costs. The main use of the DarMix+ mixer is for blending of high viscosity liquids with low viscosity liquids. It can also be used to create light emulsions. Typical applications are: Low fat spreads, butter and margarine, Fruit puree and culture, colour and flavour blending in high viscous phases such as processed cheese