Features & Benefits

All product contact components are precision-machined from wrought 316L stainless steel with less than 5% ferrite content and a 20 Ra surface finish. Material heat numbers are available for all contact components, ensuring traceability and compliance.

Standard Features and Benefits

- Cleanable-in-Place (CIP) design for hygienic processing

- High efficiency, low NPSHR design suitable for a wide range of applications

- Single mechanical seal size across all S200 Series models to reduce inventory and cost (commercial seals available)

- Integral impeller/shaft design for fewer parts, improved concentricity, and easier maintenance

- Close-coupled pumps use NEMA JM Frame motors with larger shafts and bearings than C Frame motors

- Discharge port orientations available in horizontal, vertical, and 45° angles

- Impellers, casing, and backplate machined from wrought 316L stainless steel

- Stainless steel motor adapters for enhanced durability

- Reduced validation time with comprehensive documentation package

- FDA-approved fluoroelastomers and USP Class VI elastomers for product safety

- Certified to 3-A and EHEDG hygienic standards

Key Applications

Typical product applications:

- Pharmaceutical Processing

- USP Purified Water

- USP Water for Injection

- Buffer Distribution & Transfer

- Low Viscosity Product Transfer

- CIP Solutions

|

Model |

Inlet |

Outlet Size |

Max. |

Max. Capacity GPM (M3/HR) |

Max. Head Feet (Meters) |

||

|---|---|---|---|---|---|---|---|

|

1750 RPM |

3500 RPM |

1750 RPM |

3500 RPM |

||||

|

S2045 |

1½" (38mm) |

1½" |

4½" |

97 GPM |

190 GPM |

22 ft. |

88 ft. |

|

S2065 |

2½" |

2" |

6½" |

245 GPM |

400 GPM |

47 ft. |

190 ft. |

|

S2065LV |

1½" (38mm) |

1½" |

6½" |

100 GPM |

200 GPM |

44 ft. |

180 ft. |

|

S2065HV |

3" |

2" |

6½" |

370 GPM |

500 GPM |

50 ft. |

200 ft. |

|

S2075 |

3" |

1½" |

811/16" |

125 GPM |

300 GPM |

80 ft. |

320 ft. |

|

S2085 |

3" (76mm) |

2½" |

811/16" |

480 GPM |

840 GPM |

85 ft. |

342 ft. |

|

S2085LV |

2" |

1½" |

8½" |

70 GPM |

145 GPM |

81 ft. |

330 ft. |

|

S2092 |

3" |

2" |

9¼" |

390 GPM |

700 GPM |

92 ft. |

360 ft. |

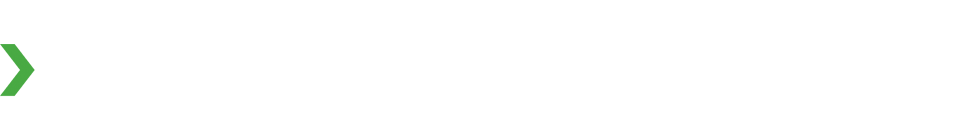

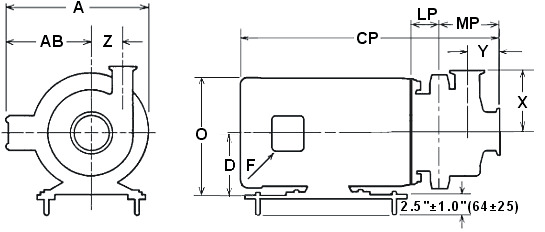

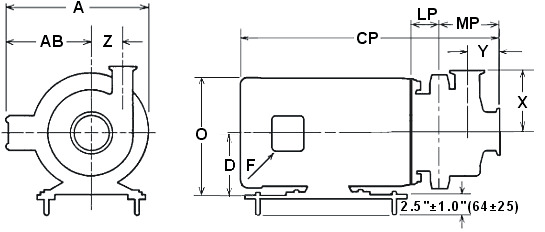

MODEL S2045

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

Unit Width Height

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

17.52 (445)

|

3.50 (89)

|

0.88 (22)

|

2.92 (74)

|

3.43 (87)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

18.90 (480)

|

4.50 (114)

|

0.88 (22)

|

2.92 (74)

|

3.43 (87)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

20.15 (512)

|

4.50 (114)

|

1.09 (28)

|

2.92 (74)

|

3.43 (87)

|

8.49 (216)

|

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

| 2045 | 1.5 (40) | 1.5 (40) | 3.88 (98) | 1.81 (46) | 2.25 (57) |

| 2045 | 2.0 (50) | 1.5 (40) | 3.88 (98) | 1.81 (46) | 2.25 (57) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

1½" x 1½" x 4½" Model S2045 - 60 Hz Pump Curve, 95-07014 || PDF

2" x 1½" x 4½" Model S2045 - 60 Hz Pump Curve, 95-07013 || PDF

60 Hz - 3500 RPM Curves:

1½" x 1½" x 4½" Model S2045 - 60 Hz Pump Curve, 95-07015 || PDF

2" x 1½" x 4½" Model S2045 - 60 Hz Pump Curve, 95-07016 || PDF

50 Hz - 1450 RPM Curves:

1½" x 1½" x 4½" Model S2045 - 50 Hz Pump Curve, 95-07046 || PDF

2" x 1½" x 4½" Model S2045 - 50 Hz Pump Curve, 95-07045 || PDF

50 Hz - 2900 RPM Curves:

1½" x 1½" x 4½" Model S2045 - 50 Hz Pump Curve, 95-07025 || PDF

2" x 1½" x 4½" Model S2045 - 50 Hz Pump Curve, 95-07026 || PDF

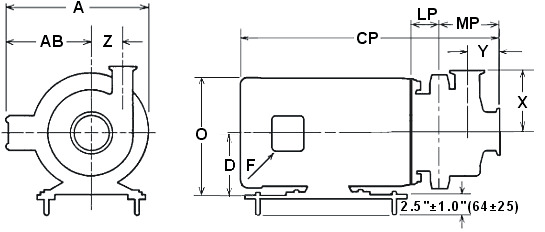

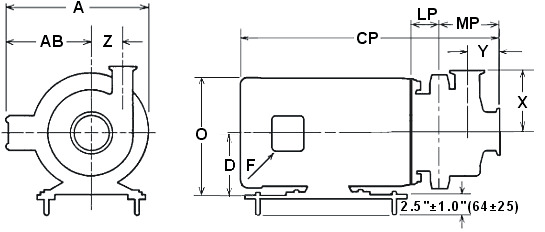

MODEL S2065

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

18.43 (468)

|

3.50 (89)

|

0.88 (22)

|

2.71 (69)

|

4.53 (115)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

19.81 (503)

|

4.50 (114)

|

0.88 (22)

|

2.71 (69)

|

4.53 (115)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

21.01 (534)

|

4.50 (114)

|

1.09 (28)

|

2.71 (69)

|

4.53 (115)

|

8.49 (216)

|

| 213JM |

13.18 (335)

|

8.04 (204)

|

22.81 (579)

|

5.25 (133)

|

1.38 (35)

|

2.97 (75)

|

4.53 (115)

|

10.39 (264)

|

| 215JM |

13.18 (335)

|

8.04 (204)

|

23.94 (608)

|

5.25 (133)

|

1.38 (35)

|

2.97 (75)

|

4.53 (115)

|

10.39 (264)

|

| 254JM |

15.34 (390)

|

9.40 (239)

|

26.07 (662)

|

6.25 (159)

|

1.38 (35)

|

3.97 (101)

|

4.53 (115)

|

11.39 (289)

|

| 256JM |

15.34 (390)

|

9.40 (239)

|

27.83 (707)

|

6.25 (159)

|

1.38 (35)

|

3.97 (101)

|

4.53 (115)

|

11.39 (289)

|

| 284JM | 20.78 (528) | 13.12 (333) | 31.43 (798) | 7.0 (178) | 2.0 (63) | 3.97 (101) | 4.53 (115) | 14.44 (367) |

| 286JM | 20.49 (520) | 13.12 (333) | 31.64 (804) | 7.0 (178) | 2.0 (63) | 3.97 (101) | 4.53 (115) | 14.44 (367) |

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

| S2065 | 2.5 (65) | 2.0 (51) | 4.94 (125) | 2.68 (68) | 2.88 (73) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

2½" x 2" x 6½" Model S2065 - 60 Hz Pump Curve, 95-07175 || PDF

60 Hz - 3500 RPM Curves:

2½" x 2" x 6½" Model S2065 - 60 Hz Pump Curve, 95-07177 || PDF

50 Hz - 1450 RPM Curves:

2½" x 2" x 6½" Model S2065 - 50 Hz Pump Curve, 95-07174 || PDF

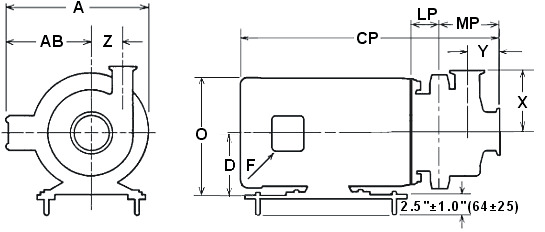

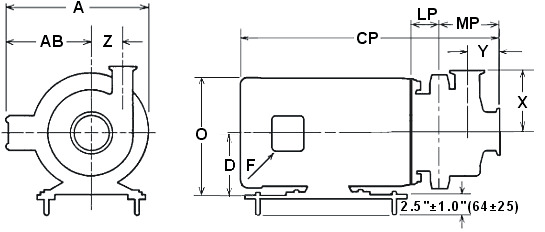

MODEL S2065HV

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

Unit Width Height

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

18.85 (479)

|

3.50 (89)

|

0.88 (22)

|

2.71 (69)

|

4.96 (126)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

20.23 (514)

|

4.50 (114)

|

0.88 (22)

|

2.71 (69)

|

4.96 (126)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

21.43 (544)

|

4.50 (114)

|

1.09 (28)

|

2.71 (69)

|

4.96 (126)

|

8.49 (216)

|

| 213JM |

13.18 (335)

|

8.04 (204)

|

23.23 (590)

|

5.25 (133)

|

1.38 (35)

|

2.97 (75)

|

4.96 (126)

|

10.39 (264)

|

| 215JM |

13.18 (335)

|

8.04 (204)

|

24.36 (618)

|

5.25 (133)

|

1.38 (35)

|

2.97 (75)

|

4.96 (126)

|

10.39 (264)

|

| 254JM |

15.34 (390)

|

9.40 (239)

|

26.49 (673)

|

6.25 (159)

|

1.38 (35)

|

3.97 (101)

|

4.96 (126)

|

11.39 (289)

|

| 256JM |

15.34 (390)

|

9.40 (239)

|

28.25 (718)

|

6.25 (159)

|

1.38 (35)

|

3.97 (101)

|

4.96 (126)

|

11.39 (289)

|

| 284JM | 20.78 (528) | 13.12 (333) | 31.85 (809) | 7.0 (178) | 2.0 (63) | 3.97 (101) | 4.96 (126) | 14.44 (367) |

| 286JM | 20.49 (520) | 13.12 (333) | 32.06 (814) | 7.0 (178) | 2.0 (63) | 3.97 (101) | 4.96 (126) | 14.44 (367) |

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

|

S2065HV |

3.0 (76) |

2.0 (51) |

4.94 (125) |

3.04 (77) |

2.88 (73) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

60 Hz - 3500 RPM Curves:

50 Hz - 1450 RPM Curves:

50 Hz - 2900 RPM Curves:

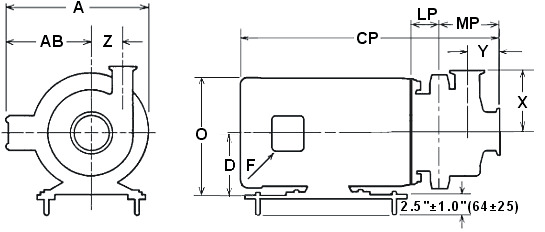

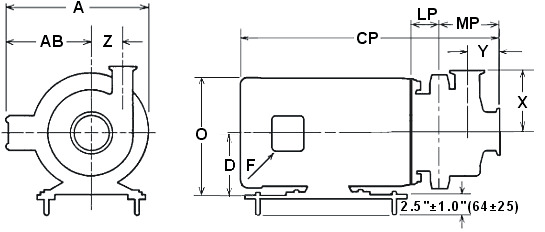

MODEL S2065LV

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

17.93 (455)

|

3.50 (89)

|

0.88 (22)

|

2.71 (69)

|

4.03 (102)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

19.31 (490)

|

4.50 (114)

|

0.88 (22)

|

2.71 (69)

|

4.03 (102)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

20.56 (522)

|

4.50 (114)

|

1.09 (28)

|

2.71 (69)

|

4.03 (102)

|

8.49 (216)

|

| 213JM |

13.18 (335)

|

8.04 (204)

|

22.31 (567)

|

5.25 (133)

|

1.38 (35)

|

2.97 (75)

|

4.03 (102)

|

10.39 (264)

|

| 215JM |

13.18 (335)

|

8.04 (204)

|

23.44 (595)

|

5.25 (133)

|

1.38 (35)

|

2.97 (75)

|

4.03 (102)

|

10.39 (264)

|

| 254JM |

15.34 (390)

|

9.40 (239)

|

25.57 (649)

|

6.25 (159)

|

1.38 (35)

|

3.97 (101)

|

4.03 (102)

|

11.39 (289)

|

| 256JM |

15.34 (390)

|

9.40 (239)

|

27.33 (694)

|

6.25 (159)

|

1.38 (35)

|

3.97 (101)

|

4.03 (102)

|

11.39 (289)

|

| 284JM | 20.78 (528) | 13.12 (333) | 30.93 (786) | 7.0 (178) | 2.0 (63) | 3.97 (101) | 4.03 (102) | 14.44 (367) |

| 286JM | 20.49 (520) | 13.12 (333) | 31.14 (791) | 7.0 (178) | 2.0 (63) | 3.97 (101) | 4.03 (102) | 14.44 (367) |

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

|

S2065LV |

1.5 (38) |

1.5 (38) |

4.94 (125) |

2.43 (62) |

3.13 (79) |

|

S2065LV |

2.0 (51) |

1.5 (38) |

4.94 (125) |

2.43 (62) |

3.13 (79) |

|

S2065LV |

2.5 (65) |

1.5 (38) |

4.94 (125) |

2.43 (62) |

3.13 (79) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

60 Hz - 3500 RPM Curves:

50 Hz - 1450 RPM Curves:

50 Hz - 2900 RPM Curves:

MODEL S2075

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

Unit Width Height

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

18.17 (461)

|

3.50 (89)

|

0.88 (22)

|

2.75 (70)

|

4.24 (108)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

19.55 (497)

|

4.50 (114)

|

0.88 (22)

|

2.75 (70)

|

4.24 (108)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

20.80 (528)

|

4.50 (114)

|

1.09 (28)

|

2.75 (70)

|

4.24 (108)

|

8.49 (216)

|

| 213JM |

13.18 (335)

|

8.04 (204)

|

22.39 (569)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.24 (108)

|

10.39 (264)

|

| 215JM |

13.18 (335)

|

8.04 (204)

|

23.52 (597)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.24 (108)

|

10.39 (264)

|

| 254JM |

15.34 (390)

|

9.40 (239)

|

25.65 (651)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.24 (108)

|

11.39 (289)

|

| 256JM |

15.34 (390)

|

9.40 (239)

|

27.41 (696)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.24 (108)

|

11.39 (289)

|

| 284JM | 20.78 (528) | 13.12 (333) | 31.01 (788) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.24 (108) | 14.44 (367) |

| 286JM | 20.49 (520) | 13.12 (333) | 31.22 (793) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.24 (108) | 14.44 (367) |

| 324JM | 23.05 (585) | 14.61 (371) | 33.11 (841) | 8.0 (203) | 2.5 (63) | 3.84 (98) | 4.24 (108) | 16.25 (413) |

| 326JM | 23.05 (585) | 14.61 (371) | 33.11 (841) | 8.0 (203) | 2.5 (63) | 3.84 (98) | 4.24 (108) | 16.25 (413) |

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

|

S2075 |

3.0 (76) |

1.5 (40) |

6.69 (170) |

2.70 (69) |

4.32 (110) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

60 Hz - 3500 RPM Curves:

50 Hz - 1450 RPM Curves:

50 Hz - 2900 RPM Curves:

MODEL S2085

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

Unit Width Height

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

18.84 (478)

|

3.50 (89)

|

0.88 (22)

|

2.75 (70)

|

4.24 (108)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

21.21 (513)

|

4.50 (114)

|

0.88 (22)

|

2.75 (70)

|

4.24 (108)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

21.46 (545)

|

4.50 (114)

|

1.09 (28)

|

2.75 (70)

|

4.24 (108)

|

8.49 (216)

|

| 213JM |

13.18 (335)

|

8.04 (204)

|

23.06 (586)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.24 (108)

|

10.39 (264)

|

| 215JM |

13.18 (335)

|

8.04 (204)

|

24.19 (614)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.24 (108)

|

10.39 (264)

|

| 254JM |

15.34 (390)

|

9.40 (239)

|

26.32 (668)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.24 (108)

|

11.39 (289)

|

| 256JM |

15.34 (390)

|

9.40 (239)

|

28.08 (713)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.24 (108)

|

11.39 (289)

|

| 284JM | 20.78 (528) | 13.12 (333) | 31.68 (805) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.24 (108) | 14.44 (367) |

| 286JM | 20.49 (520) | 13.12 (333) | 31.89 (810) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.24 (108) | 14.44 (367) |

| 324JM | 23.05 (585) | 14.61 (371) | 33.78 (858) | 8.0 (203) | 2.5 (63) | 3.84 (98) | 4.24 (108) | 16.25 (413) |

| 326JM | 23.05 (585) | 14.61 (371) | 33.78 (858) | 8.0 (203) | 2.5 (63) | 3.84 (98) | 4.24 (108) | 16.25 (413) |

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

|

S2085 |

3.0 (76) |

2.5 (64) |

5.75 (146) |

2.93 (74) |

3.82 (97) |

|

S2085 |

4.0 (102) |

2.5 (64) |

5.75 (146) |

2.93 (74) |

3.82 (97) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

3" x 2½ " x 8.7" Model S2085 - 60 Hz Pump Curve, 95-07183 || PDF

4" x 2½ " x 8.5" Model S2085 - 60 Hz Pump Curve, 95-07187 || PDF

60 Hz - 3500 RPM Curves:

3" x 2½ " x 8.7" Model S2085 - 60 Hz Pump Curve, 95-07185 || PDF

4" x 2½ " x 8.5" Model S2085 - 60 Hz Pump Curve, 95-07189 || PDF

50 Hz - 1450 RPM Curves:

3" x 2½ " x 8.7" Model S2085 - 60 Hz Pump Curve, 95-07182 || PDF

4" x 2½ " x 8.5" Model S2085 - 60 Hz Pump Curve, 95-07186 || PDF

50 Hz - 2900 RPM Curves:

3" x 2½ " x 8.7" Model S2085 - 60 Hz Pump Curve, 95-07184 || PDF

4" x 2½ " x 8.5" Model S2085 - 60 Hz Pump Curve, 95-07188 || PDF

MODEL S2085LV

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

Unit Width Height

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

18.17 (461)

|

3.50 (89)

|

0.88 (22)

|

2.75 (70)

|

4.24 (108)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

19.55 (497)

|

4.50 (114)

|

0.88 (22)

|

2.75 (70)

|

4.24 (108)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

20.80 (528)

|

4.50 (114)

|

1.09 (28)

|

2.75 (70)

|

4.24 (108)

|

8.49 (216)

|

| 213JM |

13.18 (335)

|

8.04 (204)

|

22.39 (569)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.24 (108)

|

10.39 (264)

|

| 215JM |

13.18 (335)

|

8.04 (204)

|

23.52 (597)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.24 (108)

|

10.39 (264)

|

| 254JM |

15.34 (390)

|

9.40 (239)

|

25.65 (651)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.24 (108)

|

11.39 (289)

|

| 256JM |

15.34 (390)

|

9.40 (239)

|

27.41 (696)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.24 (108)

|

11.39 (289)

|

| 284JM | 20.78 (528) | 13.12 (333) | 31.01 (788) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.24 (108) | 14.44 (367) |

| 286JM | 20.49 (520) | 13.12 (333) | 31.22 (793) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.24 (108) | 14.44 (367) |

| 324JM | 23.05 (585) | 14.61 (371) | 33.11 (841) | 8.0 (203) | 2.5 (63) | 3.84 (98) | 4.24 (108) | 16.25 (413) |

| 326JM | 23.05 (585) | 14.61 (371) | 33.11 (841) | 8.0 (203) | 2.5 (63) | 3.84 (98) | 4.24 (108) | 16.25 (413) |

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

|

S2085LV |

2.0 (51) |

1.5 (40) |

6.69 (170) |

2.70 (69) |

4.32 (110) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

60 Hz - 3500 RPM Curves:

50 Hz - 1450 RPM Curves:

50 Hz - 2900 RPM Curves:

MODEL S2092

NOTE: Pump housing may have larger diameter than motor, and require leg kit or motor shims.

Unit Width Height

| FRAME | **A in (mm) |

**AB in (mm) |

**CP in (mm) |

D in (mm) |

***F in (mm) |

LP in (mm) |

MP in (mm) |

**O in (mm) |

|---|---|---|---|---|---|---|---|---|

| 145JM |

9.32 (237)

|

5.73 (145)

|

18.78 (477)

|

3.50 (89)

|

0.88 (22)

|

2.75 (70)

|

4.85 (123)

|

7.10 (180)

|

| 182JM |

9.32 (237)

|

5.73 (145)

|

20.16 (512)

|

4.50 (114)

|

0.88 (22)

|

2.75 (70)

|

4.85 (123)

|

8.10 (206)

|

| 184JM |

11.11 (282)

|

6.87 (174)

|

21.41 (544)

|

4.50 (114)

|

1.09 (28)

|

2.75 (70)

|

4.85 (123)

|

8.49 (216)

|

| 213JM |

13.18 (335)

|

8.04 (204)

|

23.00 (584)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.85 (123)

|

10.39 (264)

|

| 215JM |

13.18 (335)

|

8.04 (204)

|

24.13 (613)

|

5.25 (133)

|

1.38 (35)

|

2.84 (72)

|

4.85 (123)

|

10.39 (264)

|

| 254JM |

15.34 (390)

|

9.40 (239)

|

26.26 (667)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.85 (123)

|

11.39 (289)

|

| 256JM |

15.34 (390)

|

9.40 (239)

|

28.02 (712)

|

6.25 (159)

|

1.38 (35)

|

3.84 (98)

|

4.85 (123)

|

11.39 (289)

|

| 284JM | 20.78 (528) | 13.12 (333) | 31.62 (803) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.85 (123) | 14.44 (367) |

| 286JM | 20.49 (520) | 13.12 (333) | 31.83 (808) | 7.0 (178) | 2.0 (63) | 3.84 (98) | 4.85 (123) | 14.44 (367) |

**Motor dimensions may vary depending on motor manufacturer

***F dimension = conduit size

NOTE: Pump dimensions are based on S-Line connectors.

Fluid Head

| MODEL | INLET in (mm) |

OUTLET in (mm) |

X in (mm) |

Y in (mm) |

Z in (mm) |

|---|---|---|---|---|---|

|

S2092 |

3.0 (76) |

2.0 (51) |

6.64 (169) |

3.09 (78) |

4.62 (117) |

Note: Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized SPX FLOW personnel prior to placing an order. SPX FLOW is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

60 Hz - 1750 RPM Curves:

60 Hz - 3500 RPM Curves:

50 Hz - 1450 RPM Curves:

50 Hz - 2900 RPM Curves:

Product Options:

- 15 or 20 Ra., electropolish and passivation product contact surface finishes

- Double mechanical seals

- Casing drain

- SS motors

- USP Class VI elastomers

- Stainless steel motors

- SS Leg Kits

- Ra Mapping

- Certified and witness performance testing

- Pedestal mounted pumps

- Stainless steel bases and coupling guards

Casing Drain Options

Front Facing - Models S2065 - S2092

|

|

|

|

| 0 DEGREE | 90 DEGREE | 45 DEGREE | LIQUID RING |

Bottom Facing - Models S2045 - S2092

|

|

|

| 0 DEGREE | 90 DEGREE | 45 DEGREE |

Tangential - Models S2045 - S2092

|

|

|

|

|

0 DEGREE LEFT FACING |

90 DEGREE LEFT FACING | 45 DEGREE LEFT FACING | LIQUID RING LEFT FACING |

|

|

|

|

| 0 DEGREE RIGHT FACING | 90 DEGREE RIGHT FACING | 45 DEGREE RIGHT FACING | LIQUID RING RIGHT FACING |

Front Facing with 90 Degree Elbow - Models S2045 - S2092

|

|

|

| 0 DEGREE | 90 DEGREE | 45 DEGREE |