Features & Benefits

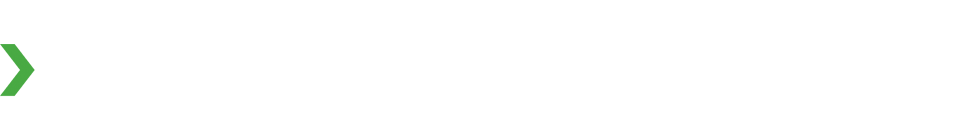

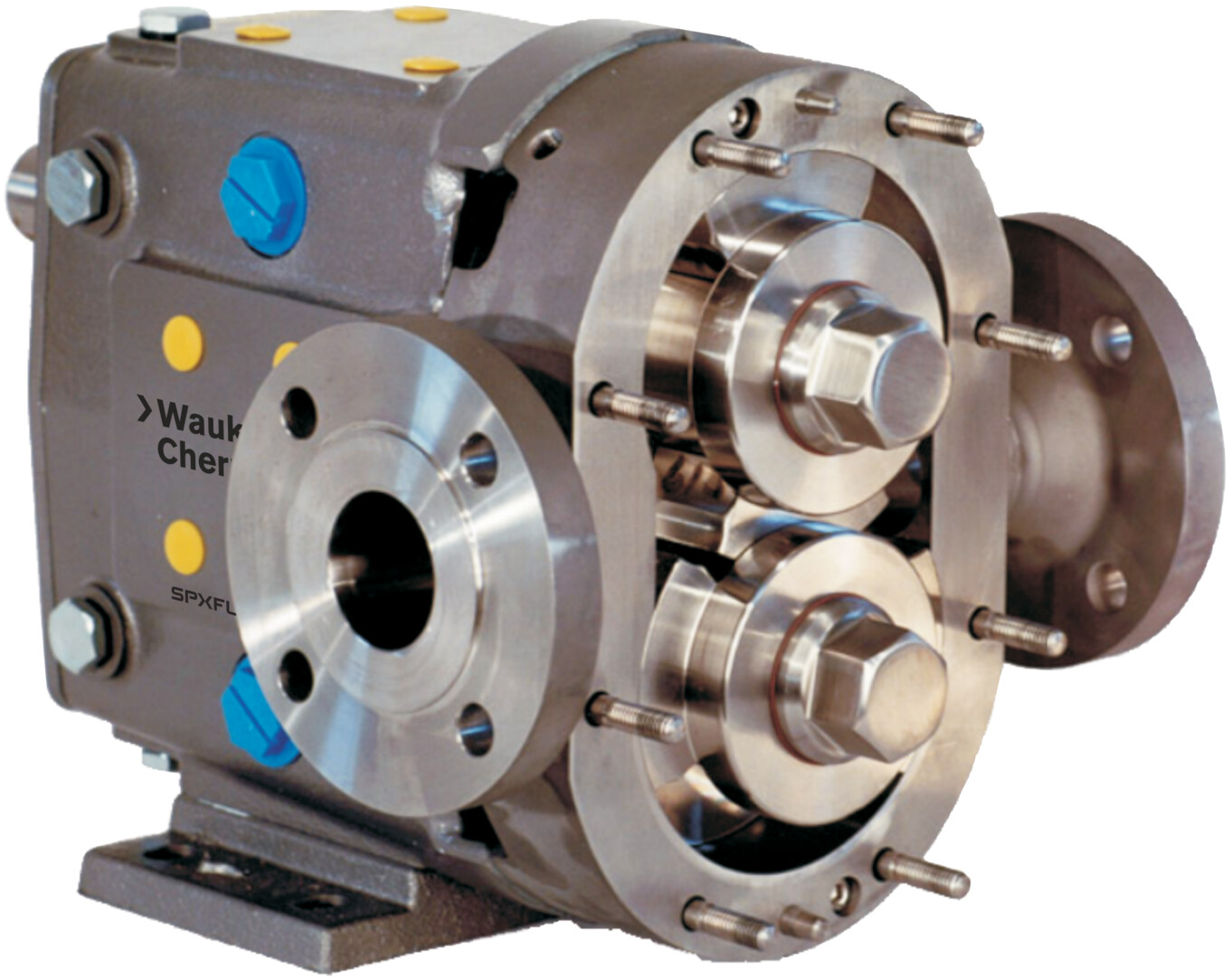

SP Universal 2 Paper Industry Pump

Learn more about our eXpress app pump services.

Specifically engineered for paper mill applications, the SP (Starch Pump) Universal 2 delivers reliable performance in demanding environments. Its ECP (External Circumferential Piston) design offers unique advantages over conventional lobe and progressing cavity pumps.

Key Advantages in Paper Mill Applications

- Starts with settled slurries without damaging pump or seals

- Can run dry indefinitely with water-flushed seals

- Low shear design protects sensitive polymers and cooked starch

- Delivers smooth, pulsation-free flow

- No internal rotor contact for reduced wear

- Shaft timing less critical than lobe pump designs

- Typically requires less horsepower than progressing cavity pumps

- Bearing isolators available for enhanced durability

ECP Positive Displacement Pump Highlights

- Handles settled slurries that jam lobe or progressing cavity pumps

- Imparts extremely low shear—ideal for fragile materials

- Designed to operate at temperatures up to 300°F (149°C)

- Not damaged by hot products

- Dry-run capable with flushed mechanical seals—no internal contact

- Meets long-standing performance demands of the paper industry

Waukesha Cherry-Burrell, an SPX FLOW brand, has led the industry in designing and manufacturing ECP-style rotary positive displacement pumps for thousands of challenging chemical and industrial applications.

Key Applications

- Coating Pigments

- Polymers

- Starch Slurry

- GCC Fillers

- PCC Fillers

- TiO2 Fillers

- Kaolin

- Cooked Starch

- Emulsions

- Resins

- Retention Aids

- TiO2 Slurry

- Specialty Chemicals

|

MODEL |

DISPLACEMENT |

NOMINAL |

INLET/ |

PRESSURE |

MAX |

TEMP |

|---|---|---|---|---|---|---|

| SP-006-U2 | 0.008 GAL. (0.031 LITER) |

8 GPM (1.8 m³/hr.) |

1" | 300 PSI (20.7 BAR) |

1000 | -40° F (-40° C) to 300° F (149° C) |

| SP-015-U2 | 0.014 GAL. (0.054 LITER) |

11 GPM (2.5 m³/hr.) |

1.5" | 250 PSI (17.2 BAR) |

800 | |

| SP-018-U2 | 0.029 GAL. (0.110 LITER) |

20 GPM (4.5 m³/hr.) |

15" | 200 PSI (13.8 BAR) |

700 | |

| SP-030-U2 | 0.060 GAL. (0.227 LITER) |

36 GPM (8.2 m³/hr.) |

1.5" | 250 PSI (17.2 BAR) |

600 | |

| SP-040-U2 | 0.076 GAL. (0.228 LITER) |

46 GPM (10.4 m³/hr.) |

2" | 150 PSI (10.5 BAR) |

600 | |

| SP-045-U2 | 0.098 GAL. (0.371 LITER) |

58 GPM (13.2 m³/hr.) |

2" | 450 PSI (31.0 BAR) |

600 | |

| SP-060-U2 | 0.153 GAL. (0.579 LITER) |

90 GPM (20.4 m³/hr.) |

2.5" | 300 PSI (20.7 BAR) |

600 | |

| SP-130-U2 | 0.253 GAL. (0.958 LITER) |

150 GPM (34.1 m³/hr.) |

3" | 200 PSI (13.8 BAR) |

600 | |

| SP-180-U2 | 0.380 GAL. (1.438 LITER) |

230 GPM (52.2 m³/hr.) |

3" | 450 PSI (31.0 BAR) |

600 | |

| SP-210-U2 | 0.502 GAL. (1.90 LITER) |

300 GPM (68.1 m³/hr.) |

4" | 500 PSI (34.5 BAR) |

600 | |

| SP-220-U2 | 0.521 GAL. (1.972 LITER) |

310 GPM (70.4 m³/hr.) |

4" | 300 PSI (20.7 BAR) |

600 | |

| SP-320-U2 | 0.752 GAL. (2.847 LITER) |

450 GPM (102 m³/hr.) |

6" | 300 PSI (20.7 BAR) |

600 | |

| SP-370-U2 | 0.752 GAL. (2.847 Liter) |

660 GPM (150 m³/hr.) |

6" | 200 PSI (13.8 bar) |

600 | |

| SP-420-UHC | 1.62 GAL. (6.13 LITER) |

649 GPM (147 m³/hr.) |

6" | 200 PSI (13.8 BAR) |

400 | |

| SP-520-UHC | 2.38 GAL. (9.00 LITER) |

830 GPM (187 m³/hr.) |

8" | 150 PSI (10.3 BAR) |

350 | |

| SP-5040 | 0.060 GAL. (.227 LITER) |

36 GPM (8.2 m³/hr.) |

1.5" | 200 PSI (13.8 BAR) |

600 | |

| SP-5050 | 0.153 GAL. (.579 LITER) |

90 GPM (20.4 m³/hr.) |

2.0" | 200 PSI (13.8 BAR) |

600 | |

| SP-5060 | 0.254 GAL. (.961 LITER) |

150 GPM (34.1 m³/hr.) |

2.5" | 200 PSI (13.8 BAR) |

600 | |

| SP-5070 | 0.440 GAL. (1.666 LITER) |

260 GPM (59.1 m³/hr.) |

4" | 200 PSI (13.8 BAR) |

600 | |

| SP-5080 | 0.754 GAL. (2.854 LITER) |

450 GPM (102 m³/hr.) |

6" | 200 PSI (13.8 BAR) |

600 |

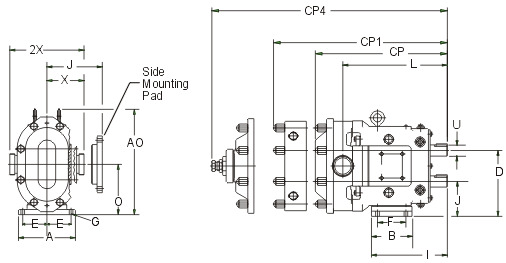

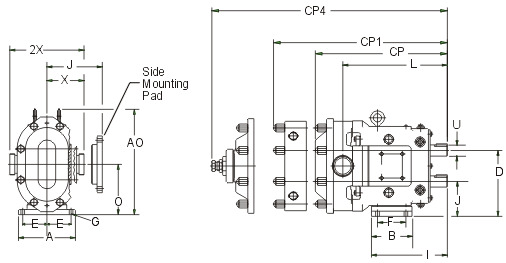

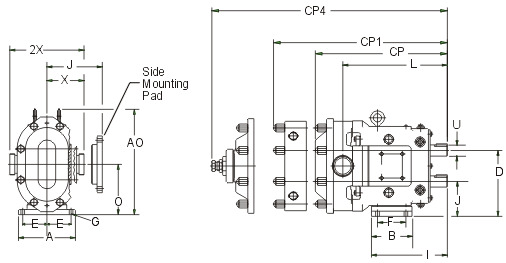

Model SP-006-U2

0-1000 RPM speed range. 1" (25.4 mm) and 1½" (38.1 mm) port sizes available; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

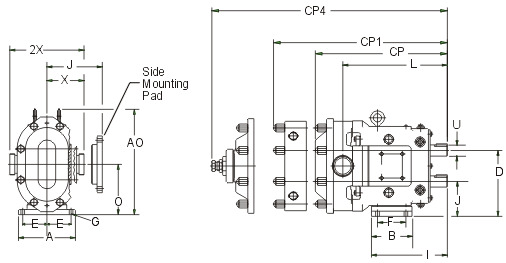

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

4.75

|

8.3

|

3.75

|

11.71

|

13.92

|

14.92

|

5.50

|

1.94

|

2.31

|

.41slot

|

7.66

|

2.93

|

9.61

|

4.21

|

.875

|

3.49

|

6.97

|

|

MM

|

121

|

211

|

95

|

297

|

354

|

379

|

140

|

49

|

59

|

10 slot

|

194

|

74

|

244

|

107

|

22.23

|

89

|

177

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U2 to 030-U2, 1"-11- NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 56 lb. (25.4 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

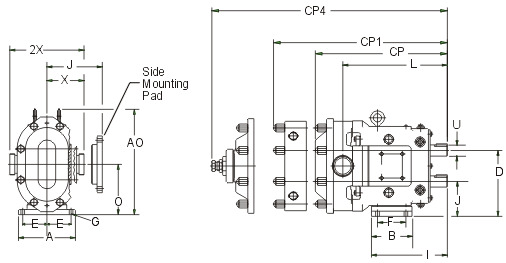

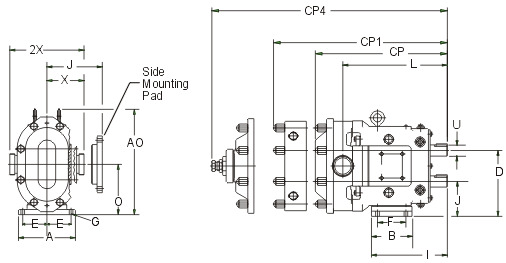

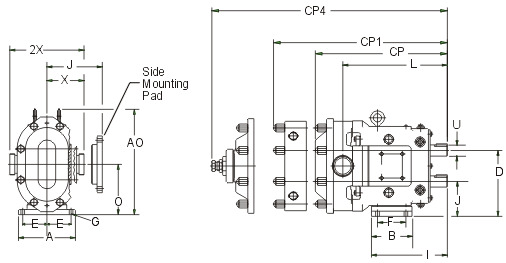

Model SP-015-U2

0-1000 RPM speed range. 1½" (38.1 mm) port sizes available; suitable to 250 PSI (17.2 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

4.75

|

8.3

|

3.75

|

11.71

|

13.92

|

14.92

|

5.50

|

1.94

|

2.31

|

.41slot

|

7.66

|

2.93

|

9.61

|

4.21

|

.875

|

3.49

|

6.97

|

|

MM

|

121

|

211

|

95

|

297

|

354

|

379

|

140

|

49

|

59

|

10 slot

|

194

|

74

|

244

|

107

|

22.23

|

89

|

177

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 56 lb. (25.4 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

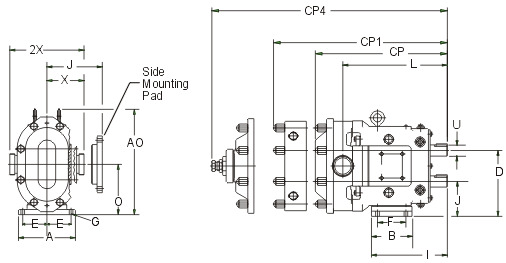

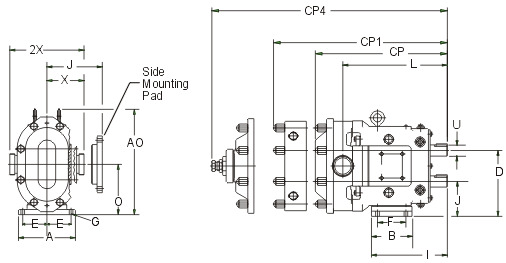

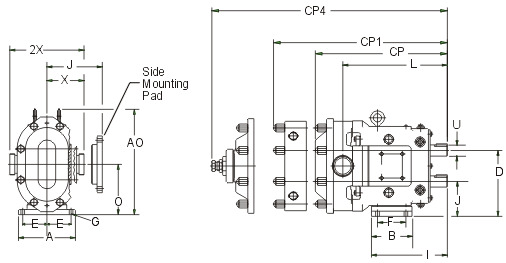

Model SP-018-U2

0-700 RPM speed range. 1½" (38.1 mm) and 2" (50.8 mm) port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

4.75

|

8.3

|

3.75

|

12.37

|

14.59

|

15.58

|

5.50

|

1.94

|

2.31

|

.41slot

|

7.66

|

2.93

|

9.84

|

4.21

|

.875

|

3.49

|

6.97

|

|

MM

|

121

|

211

|

95

|

314

|

371

|

396

|

140

|

49

|

59

|

10 slot

|

194

|

74

|

250

|

107

|

22.23

|

89

|

177

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 65 lb. (29.5 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

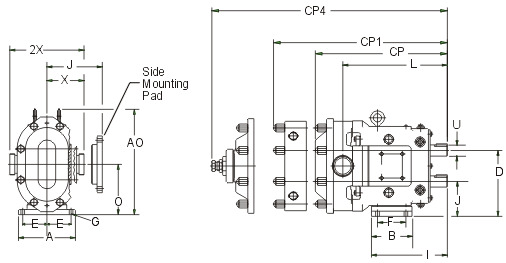

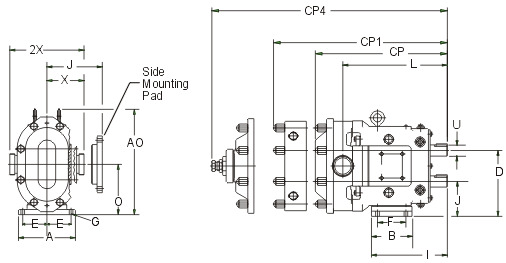

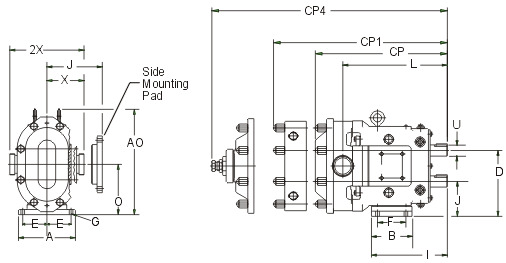

Model SP-030-U2

0-600 RPM speed range. 1½" (38.1 mm) and 2" (50.8 mm) port sizes available; suitable to 250 PSI (17.2 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

6.25

|

10.29

|

4.25

|

14.49

|

16.49

|

17.58

|

6.86

|

2.31

|

2.56

|

.41slot

|

8.83

|

3.56

|

11.61

|

5.21

|

1.25

|

4.25

|

8.5

|

|

MM

|

159

|

261

|

108

|

368

|

419

|

447

|

174

|

59

|

65

|

10 slot

|

224

|

90

|

295

|

132

|

31.75

|

108

|

216

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 130 lb. (59.0 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-040-U2

0-600 RPM speed range. 2" (50.8 mm) port size available; suitable to 150 PSI (10 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

6.25

|

10.29

|

4.25

|

14.87

|

16.87

|

17.96

|

6.86

|

2.31

|

2.56

|

.41slot

|

8.83

|

3.56

|

11.99

|

5.21

|

1.25

|

4.31

|

8.62

|

|

MM

|

159

|

261

|

108

|

378

|

428

|

456

|

174

|

59

|

65

|

10 slot

|

224

|

90

|

305

|

132

|

31.75

|

109

|

219

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 140 lb. (64.0 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-045-U2

0-600 RPM speed range. 2" (50.8 mm) port sizes available; suitable to 450 PSI (31.0 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.25

|

15.31

|

5.87

|

18.59

|

20.70

|

22.28

|

9.56

|

3.50

|

4.12

|

.53

|

10.99

|

5.06

|

14.86

|

7.31

|

1.625

|

5.37

|

10.75

|

|

MM

|

210

|

389

|

149

|

472

|

526

|

566

|

243

|

89

|

105

|

13

|

279

|

129

|

377

|

186

|

41.28

|

136

|

273

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 295 lb. (134.0 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-060-U2

0-600 RPM speed range. 2½" (63.5 mm) port sizes available; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.25

|

15.31

|

5.87

|

19.14

|

21.25

|

22.83

|

9.56

|

3.50

|

4.12

|

.53

|

10.99

|

5.06

|

15.14

|

7.31

|

1.625

|

5.37

|

10.75

|

|

MM

|

210

|

389

|

149

|

486

|

540

|

580

|

243

|

89

|

105

|

13

|

279

|

129

|

385

|

186

|

41.28

|

136

|

273

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U2 to 030-U2, 1"-11- NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 285 lb. (129.3 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-130-U2

0-600 RPM speed range. 3" (76.2 mm) port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.25

|

15.31

|

5.87

|

20.15

|

22.27

|

23.84

|

9.56

|

3.50

|

4.12

|

.53

|

10.99

|

5.06

|

15.77

|

7.31

|

1.625

|

5.37

|

10.75

|

|

MM

|

210

|

389

|

149

|

512

|

566

|

606

|

243

|

89

|

105

|

13

|

279

|

129

|

401

|

186

|

41.28

|

136

|

273

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 305 lb. (138.3 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-180-U2

0-600 RPM speed range. 3" (76.2 mm) port sizes available; suitable to 450 PSI (31.0 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.50

|

19.13

|

9.00

|

23.26

|

25.32

|

28.51

|

12.38

|

3.75

|

7.25

|

.53 slot

|

14.80

|

6.38

|

18.25

|

9.38

|

2.0

|

6.53

|

13.06

|

|

MM

|

216

|

486

|

2.29

|

591

|

643

|

724

|

314

|

95

|

184

|

13 slot

|

376

|

162

|

464

|

238

|

50.8

|

168

|

337

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 520 lb. (236.0 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-210-U2

0-600 RPM speed range. 4" (101.6 mm) port sizes available; suitable to 500 PSI (34.5 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

12.00

|

22.38

|

11.63

|

27.08

|

28.58

|

--

|

13.88

|

5.25

|

8.00

|

.66

|

17.80

|

6.88

|

21.24

|

10.38

|

2.375

|

7.37

|

14.73

|

|

MM

|

305

|

568

|

295

|

688

|

726

|

--

|

353

|

133

|

203

|

17

|

452

|

175

|

539

|

264

|

60.45

|

187

|

374

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 915 lb. (415.0 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-220-U2

0-600 RPM speed range. 4" (101.6 mm) port sizes available; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.50

|

19.13

|

9.00

|

24.00

|

26.06

|

29.25

|

12.38

|

3.75

|

7.25

|

.53 slot

|

14.80

|

6.38

|

18.49

|

9.38

|

2.000

|

6.63

|

13.25

|

|

MM

|

216

|

486

|

229

|

610

|

662

|

743

|

314

|

95

|

184

|

13 slot

|

376

|

162

|

470

|

238

|

50.80

|

168

|

337

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 590 lb. (268.0 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-320-U2

0-600 RPM speed range. 6" (152.4 mm) port sizes available; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

CP4

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

12.00

|

22.38

|

11.63

|

27.66

|

29.16

|

--

|

13.88

|

5.25

|

8.00

|

.66

|

17.80

|

6.88

|

21.63

|

10.38

|

2.375

|

8.00

|

16.00

|

|

MM

|

305

|

568

|

295

|

703

|

741

|

--

|

358

|

133

|

203

|

17

|

452

|

175

|

549

|

264

|

60.45

|

203

|

406

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 895 lb. (406.0 kg.).

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Model SP-370-U2

0-600 RPM speed range. 6" (152.4 mm) port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AO

|

B

|

CP

|

CP1

|

D

|

E

|

F

|

G

|

I

|

J

|

L

|

O

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

12.00

|

22.38

|

11.63

|

29.16

|

30.66

|

13.88

|

5.25

|

8.00

|

.66

|

17.80

|

6.88

|

22.32

|

10.38

|

2.38

|

8.50

|

17.00

|

|

MM

|

305

|

568

|

295

|

741

|

779

|

353

|

133

|

203

|

17

|

452

|

175

|

567

|

264

|

60.5

|

216

|

432

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U2 to 030-U2, 1"-11-½ NPT on Models 042-U2 to 220-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320 U2).

Approximate shipping weight 945 lb. (428.6 kg.)

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Ports

- Standard Sanitary Clamp Type Is available in a variety of styles including S-Line, I-Line and Q-Line

- Bevel Seat Available

- Optional European Types; DIN, SMS, RJT

- Male NPT and 150 lb. flanges optional on Models 006 through 220 size

- 150 lb. flanges standard

- Contact factory for available rectangular flange inlets.

Rotors

- Twin Wing - Standard; suitable for most applications.

- Twin Wing with wear ring - option

Rotor clearance

- Standard for most applications up to 180°F (82°C).

- Hot clearance rotors option for applications up to 300°F (149°C).

- Other special clearances available.

O-Rings Standard: Fluoroelastomer (FKM) Options:

- Buna-N

- Buna-N - Metal Detectable

- EPDM

- PTFM/FFKM

- Perfluoroelastomer (FFKM)

- Silicone

- Fluoroelastomer (FKM) - Metal Detectable

- EPDM - Metal Detectable

Cover & Gearcase Standard: Steel-It paint gearcase, 17-4 stainless steel shafts, stainless steel bearing retainers Options:

- Stainless steel gearcase

- 316L stainless steel shafts

- Lower shaft position

- Bearing Isolators

- Pedestal shims for side mounted pumps. Left hand shaft position standard.

- Right hand shaft position on side mounted gearcase

Tru-Fit® Close coupled Tru-Fit® pump mounted on stainless steel base with stainless steel adaptors standard. Features:

- No shaft alignment necessary. No coupling guard required.

- Special base design enhances cleanability.

- Reduces overall length of complete unit by an average of 20-25%.

- Average of 20-25 gear ratios available per horsepower.

- Separate oil sump for gear reducer and timing gears.

Options:

- 304 SS polished plate base.

- NEMA or IEC frames available. Right angle reducer also available foradditional space savings.

- 1/2 through 60 horsepower drive options available.

- Horizontal or vertical porting.