Inlet Port Range

Six models feature inlet ports ranging in size from 7.13 to 86.87 square inches, offering flexibility for various flow requirements.

Benefits

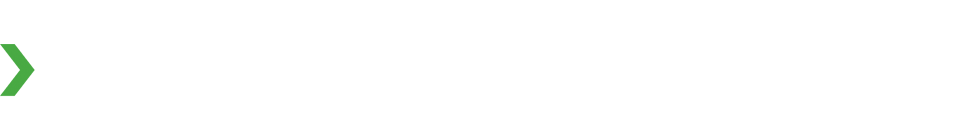

- 316 stainless steel body for corrosion resistance and durability

- Large, rectangular inlet port for improved flow efficiency

- Non-galling Waukesha "88" alloy rotors for long-lasting performance

- Maximum pressure: 200 psi (13.8 bar) *

- Temperature range: -40°F (-40°C) to 300°F (149°C)

*Contact Application Engineering for higher pressure or temperature requirements.

Explore our eXpress app pump services for more details.

|

MODEL |

DISPLACEMENT |

NOMINAL |

MAXIMUM |

|---|---|---|---|

| 014-U2 | 0.0142 GAL. (0.054 Liter) | 5.68 GPM (1.3 m³/hr.) | 200 PSI (13.8 bar) |

| 034-U2 | 0.060 GAL. (0.227 Liter) | 24 GPM (5.5 m³/hr.) | 250 PSI (17.2 bar) |

| 064-U2 | 0.153 GAL. (0.579 Liter) | 61 GPM (13.9 m³/hr.) | 300 PSI (20.7 bar) |

| 134-U2 | 0.253 GAL. (.958 Liter) | 101 GPM (22.9 m³/hr.) | 200 PSI (13.8 bar) |

|

184-U2

|

0.380 GAL. (1.438 Liter)

|

152 GPM (34.5 m³/hr.)

|

450 PSI (31.0 bar)

|

| 214-U2 | 0.502 GAL. (1.90 Liter) | 200 GPM (45.4 m³/hr.) | 500 PSI (34.5 bar) |

| 224-U2 | 0.521 GAL. (1.972 Liter) | 208 GPM (47.2 m³/hr.) | 300 PSI (20.7 bar) |

| 324-U2 | 0.752 GAL. (2.847 Liter) | 300 GPM (68.1 m³/hr.) | 300 PSI (20.7 bar) |

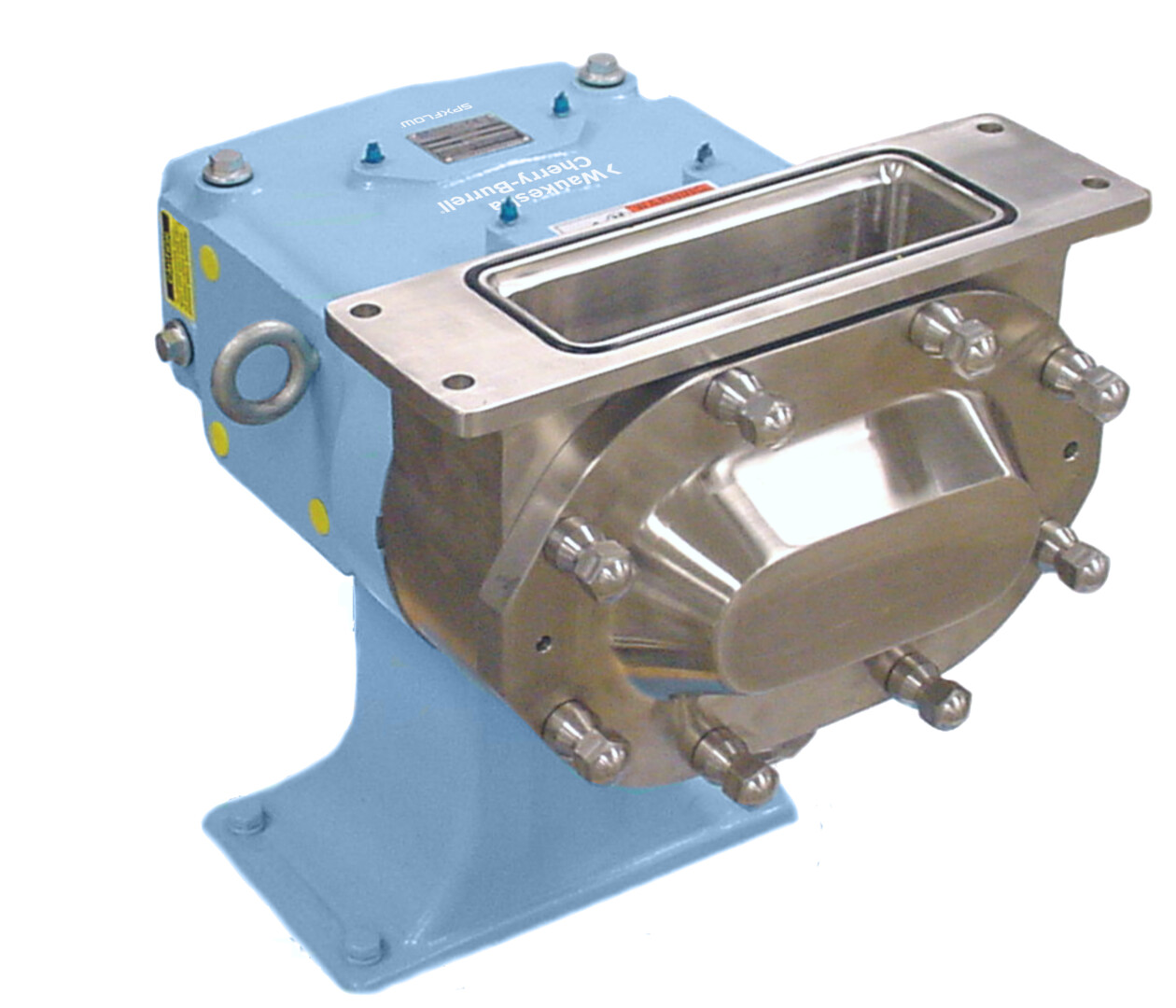

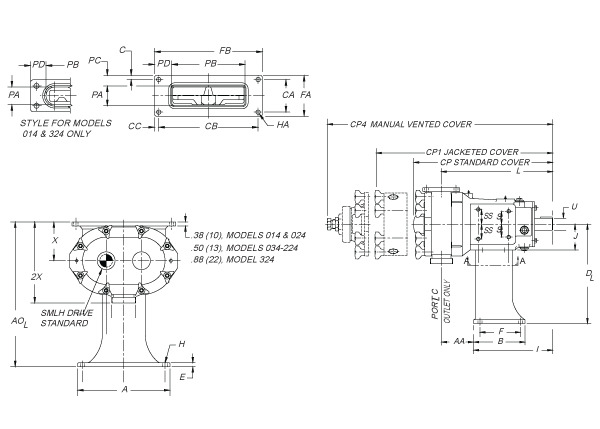

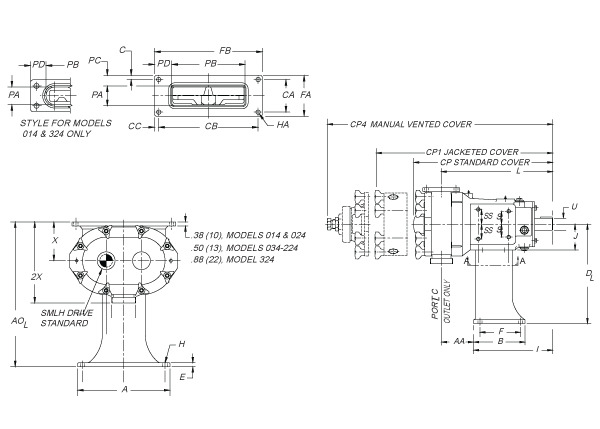

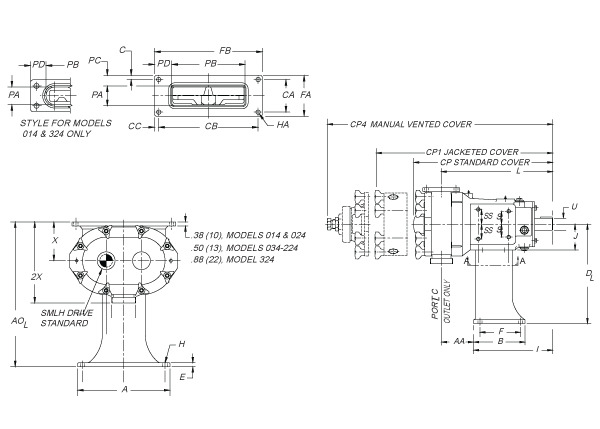

MODEL 014

0-600 RPM speed range. 1½" (38.1 mm) discharge port; suitable to 250 PSI (17.2 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

6.75

|

1.95

|

12.50

|

4.13

|

11.71

|

13.92

|

14.92

|

8.88

|

.38

|

2.31

|

.41

|

7.66

|

2.12

|

9.61

|

.875

|

3.63

|

7.11

|

|

MM

|

171

|

50

|

318

|

105

|

297

|

354

|

379

|

226

|

10

|

59

|

10

|

195

|

54

|

244

|

22.23

|

92

|

181

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.50

|

1.62

|

6.50

|

.50

|

2.63

|

7.50

|

.41

|

1.44

|

4.94

|

.59

|

1.28

|

|

MM

|

13

|

41

|

165

|

13

|

67

|

191

|

10

|

37

|

125

|

15

|

33

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 66 lb. (30 kg.) pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

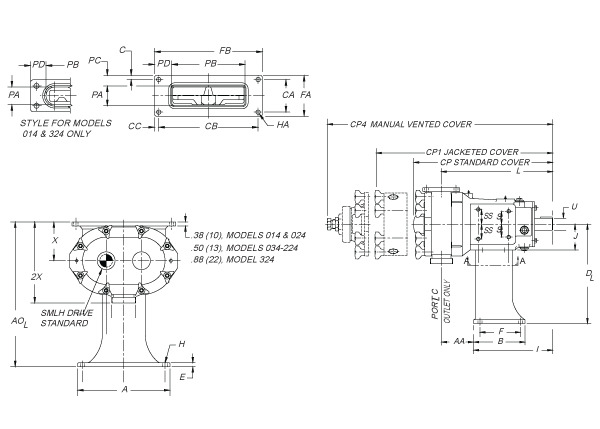

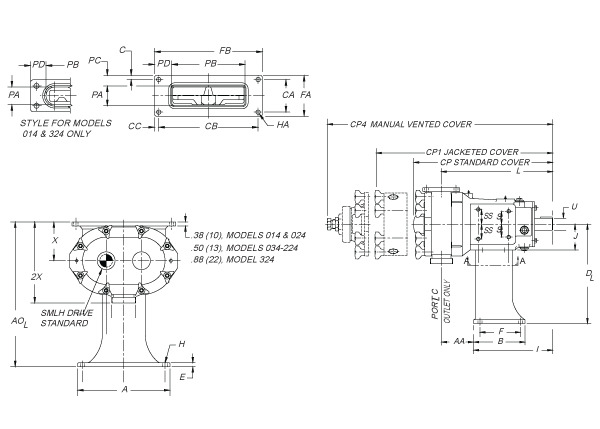

MODEL 034

0-800 RPM speed range. 2" discharge port; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.00

|

2.88

|

12.75

|

4.25

|

14.49

|

16.49

|

17.58

|

8.88

|

.38

|

3.00

|

.44

|

8.49

|

2.62

|

11.37

|

1.250

|

3.88

|

8.12

|

|

MM

|

203

|

73

|

324

|

108

|

368

|

419

|

447

|

226

|

10

|

76

|

11

|

216

|

67

|

289

|

31.75

|

99

|

206

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.62

|

1.88

|

10.75

|

.62

|

3.12

|

12.00

|

.53

|

1.81

|

6.84

|

.66

|

2.58

|

|

MM

|

16

|

48

|

273

|

16

|

79

|

305

|

13

|

46

|

174

|

17

|

66

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 140 lb. (64 kg.). pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

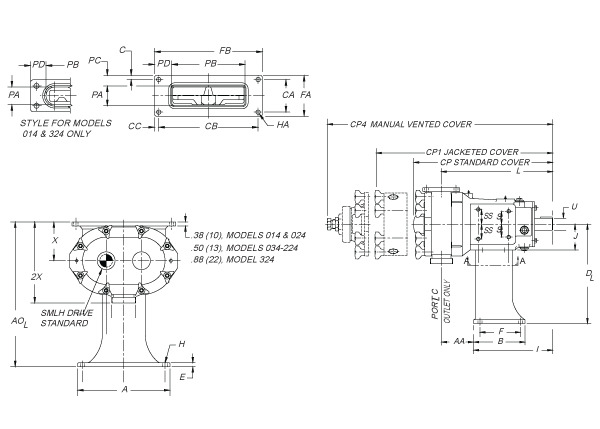

MODEL 064

0-800 RPM speed range. 2½" discharge port; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

11.75

|

4.35

|

13.94

|

7.00

|

19.14

|

21.25

|

22.83

|

9.00

|

.50

|

5.50

|

.56

|

10.77

|

3.50

|

15.16

|

1.625

|

4.94

|

10.31

|

|

MM

|

298

|

110

|

354

|

178

|

486

|

540

|

580

|

229

|

13

|

140

|

14

|

274

|

89

|

385

|

41.28

|

125

|

262

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.50

|

4.00

|

12.20

|

.52

|

5.00

|

13.23

|

.53

|

2.44

|

9.00

|

1.28

|

2.11

|

|

MM

|

13

|

102

|

310

|

13

|

127

|

336

|

13

|

62

|

229

|

33

|

54

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 297 lb. (135 kg.) pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

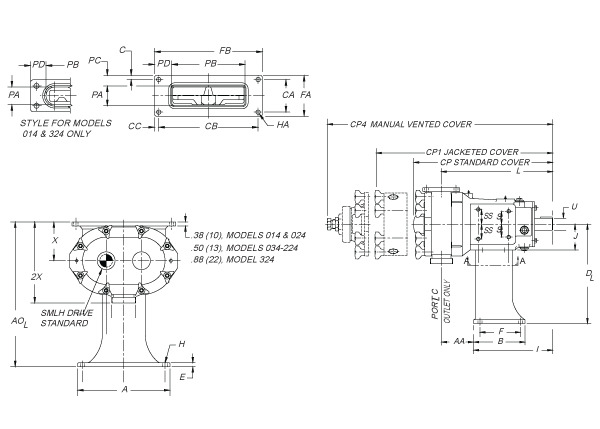

MODEL 134

0-800 RPM speed range. 3" discharge port; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

11.75

|

5.00

|

13.94

|

7.00

|

20.15

|

22.27

|

23.84

|

9.00

|

.50

|

5.50

|

.56

|

10.77

|

3.50

|

15.78

|

1.625

|

4.94

|

10.31

|

|

MM

|

298

|

127

|

354

|

178

|

512

|

566

|

606

|

229

|

13

|

140

|

14

|

274

|

89

|

401

|

41.28

|

125

|

262

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.78

|

3.00

|

14.00

|

.63

|

4.55

|

15.25

|

.53

|

3.19

|

9.38

|

.68

|

2.94

|

|

MM

|

20

|

76

|

356

|

16

|

116

|

387

|

13

|

81

|

238

|

17

|

75

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 317 lb. (144 kg.) pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

MODEL 184

0-800 RPM speed range. 3" discharge port; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

15.00

|

4.32

|

35.94

|

9.50

|

23.26

|

25.32

|

28.51

|

13.50

|

.63

|

8.25

|

.56

|

13.74

|

4.50

|

18.31

|

2.00

|

7.25

|

13.78

|

|

MM

|

381

|

110

|

913

|

241

|

591

|

643

|

724

|

343

|

16

|

210

|

14

|

349

|

114

|

465

|

50.80

|

184

|

350

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.63

|

5.75

|

16.75

|

.63

|

7.00

|

18.00

|

.53

|

3.28

|

11.25

|

1.86

|

3.38

|

|

MM

|

16

|

146

|

425

|

16

|

178

|

457

|

13

|

83

|

286

|

47

|

86

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 535 lb. (243 kg.) pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

MODEL 214

0-800 RPM speed range. 4" discharge port; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

18.00

|

4.38

|

35.94

|

12.00

|

27.08

|

28.58

|

-

|

27.13

|

.75

|

9.50

|

.69

|

16.86

|

5.06

|

21.26

|

2.375

|

8.81

|

16.17

|

|

MM

|

457

|

111

|

913

|

305

|

688

|

726

|

-

|

689

|

19

|

241

|

18

|

428

|

129

|

540

|

60.33

|

224

|

411

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.75

|

7.50

|

16.5

|

.75

|

9.00

|

18.00

|

.69

|

3.45

|

12.70

|

2.78

|

2.65

|

|

MM

|

21

|

203

|

419

|

19

|

229

|

457

|

18

|

88

|

323

|

71

|

67

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 933 lb. (423 kg.) pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

MODEL 224

0-600 RPM speed range. 4" (101.6 mm) discharge port size; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

15.00

|

4.75

|

19.75

|

9.50

|

24.00

|

26.06

|

29.25

|

13.50

|

.63

|

8.25

|

.56

|

13.74

|

4.50

|

18.49

|

2.00

|

6.25

|

12.87

|

|

MM

|

381

|

121

|

502

|

241

|

610

|

662

|

743

|

343

|

16

|

210

|

14

|

349

|

114

|

470

|

50.80

|

159

|

327

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.63

|

4.37

|

16.75

|

.63

|

5.62

|

18.00

|

.53

|

4.06

|

11.25

|

.78

|

3.38

|

|

MM

|

16

|

111

|

425

|

16

|

143

|

457

|

13

|

103

|

286

|

20

|

86

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 605 lb. (274 kg.) pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

MODEL 324

0-600 RPM speed range. 6" (152.4 mm) discharge port size; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

|

|

A

|

AA

|

AOL

|

B

|

CP

|

CP1

|

CP4

|

DL

|

E

|

F

|

H

|

I

|

J

|

L

|

U

|

X

|

2X

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

18.00

|

4.79

|

35.94

|

12.00

|

27.66

|

29.16

|

-

|

27.13

|

.75

|

9.50

|

.69

|

16.86

|

5.06

|

21.63

|

2.375

|

8.81

|

17.81

|

|

MM

|

457

|

122

|

913

|

305

|

703

|

741

|

-

|

689

|

19

|

241

|

18

|

428

|

129

|

549

|

60.33

|

224

|

452

|

|

|

C

|

CA

|

CB

|

CC

|

FA

|

FB

|

HA

|

PA

|

PB

|

PC

|

PD

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

.81

|

8.00

|

16.5

|

.75

|

9.63

|

18.00

|

.69

|

4.25

|

12.70

|

2.69

|

2.65

|

|

MM

|

21

|

203

|

419

|

19

|

245

|

457

|

18

|

108

|

323

|

68

|

67

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 014-U2 to 034-U2, 1"-11-½ NPT on Models 064-U2 and 134-U2.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 913 lb. (414 kg.) pump only.

NOTES: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed. Waukesha Cherry-Burrell (WCB) curves are intended for use as an aid for preliminary selection of pumps by trained and qualified engineers. All selections must be reviewed by authorized WCB personnel prior to placing an order. WCB is not responsible for unauthorized or incorrect selections resulting from the use of these curves.

Ports Standard: Sanitary Clamp Type Is available in a variety of styles including S-Line, I-Line and Q-Line Options:

- Bevel Seat Available

- Optional European Types; DIN, SMS, RJT

- Male NPT and 150 lb. flange optional on Models 014 through 324 size

- 150 lb. flange standard on Model 324

- Contact factory for available rectangular flange inlets

Rotors Standard: Twin Wing - Standard; suitable for most application

- Single Wing - For reduced breakage on fluids with discrete particulates, such as diced tomato products

Rotor clearance Standard: up to 180°F (82°C) Options:

- Hot clearance rotors option for applications up to 300°F (149°C)

- Other special clearances available

O-Rings Standard: Buna-N Options:

- PTFE/FFKM

- Fluoroelastomer (FKM)

- Fluoroelastomer (FKM) - Class 6

- EPDM

- EPDM - SF

- EPDM - Class 6

- Silicone

- Perfluoroelastomer (FFKM)

- FEP Encapsulates

- Buna-N - Metal Detectable

- FKM - Metal Detectable

- EPDM - Metal Detectable

Cover & Gearcase Standard: cast iron powder coated gearcase, 17-4 stainless steel shafts, stainless steel bearing retainers Options:

- Stainless steel gearcase

- 316L stainless steel shafts

- Steel-It paint

- Lower shaft position

- Bearing Isolators

- Pedestal shims for side mounted pumps. Left hand shaft position standard.

- Right hand shaft position on side mounted gearcase

Tru-Fit® Close coupled Tru-Fit® pump mounted on stainless steel base with stainless steel adaptors standard. Features:

- No shaft alignment necessary. No coupling guard required.

- Special base design enhances cleanability.

- Reduces overall length of complete unit by an average of 20-25%.

- Average of 20-25 gear ratios available per horsepower.

- Separate oil sump for gear reducer and timing gears.

Options:

- 304 SS polished plate base.

- NEMA or IEC frames available. Right angle reducer also available for additional space savings.

- 1/2 through 60 horsepower drive options available.

- Horizontal or vertical porting.